Leave Your Message

-

Phone

-

E-mail

In the realm of modern manufacturing, the choice of materials and production methods plays a pivotal role in determining the efficiency and quality of the final products. One of the standout options in this landscape is the use of brass forging parts, which offer a myriad of advantages that can greatly enhance manufacturing processes. Brass forging parts are renowned for their exceptional strength, durability, and resistance to corrosion, making them ideal for a variety of applications across industries such as automotive, aerospace, and electronics.

This blog will delve into the multifaceted benefits of utilizing brass forging parts, from improved structural integrity to cost-effectiveness in production. By exploring these advantages, manufacturers can make informed decisions that not only optimize their operations but also contribute to the sustainability and longevity of their products in an increasingly competitive market.

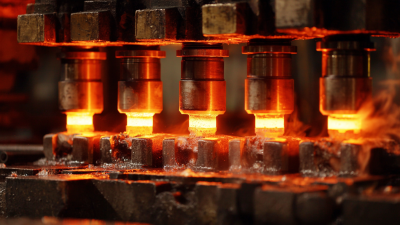

Brass forging has emerged as a vital technique in modern manufacturing, leveraging its unique properties for a range of applications. One of the key benefits of brass forging is its excellent strength-to-weight ratio, which makes it an ideal choice for components that require both durability and reduced weight. Additionally, brass exhibits superb corrosion resistance, allowing forged parts to withstand harsh environments without significant degradation. These characteristics make brass an ideal material for industries such as automotive, aerospace, and plumbing.

When considering brass forging for your manufacturing needs, it's essential to evaluate the specific requirements of your project. Tip: Focus on the appropriate alloy of brass that matches your application demands, as different compositions can significantly affect mechanical properties. Furthermore, ensuring that you partner with an experienced forging manufacturer can greatly influence the quality and precision of the final product. Tip: Always request samples or get references from previous clients to assess the manufacturer's capabilities.

Investing in brass forging technology not only enhances product longevity but can also improve overall operational efficiency. Tip: Take the time to analyze the long-term cost benefits associated with reduced maintenance and increased reliability of forged brass components. Embracing this manufacturing process can drive innovation and elevate product performance across various sectors.

| Property | Description | Advantages |

|---|---|---|

| Corrosion Resistance | Brass has a high resistance to corrosion, particularly in moist environments. | Increased durability and lifespan of parts, reducing maintenance costs. |

| Malleability | Brass is highly malleable, allowing it to be shaped without breaking. | Flexibility in manufacturing designs and custom shapes. |

| Electrical Conductivity | Brass conducts electricity well, though not as efficiently as copper. | Ideal for electrical components and connectors. |

| Aesthetic Appeal | Brass has a bright, gold-like appearance that is visually appealing. | Used in decorative applications and products. |

| Thermal Conductivity | Brass conducts heat effectively. | Beneficial for components that require heat dissipation. |

Brass forging has emerged as a key process in modern manufacturing, leveraging the unique properties of brass to produce durable and high-precision components. The forging process involves shaping heated brass through compressive forces, which aligns the metal's grain structure, enhancing its strength and ductility. According to a recent report by the U.S. Department of Commerce, brass components exhibit up to 30% higher tensile strength compared to other materials commonly used in manufacturing. This increased strength translates to longer-lasting products and reduced maintenance costs in various applications, from automotive parts to plumbing fixtures.

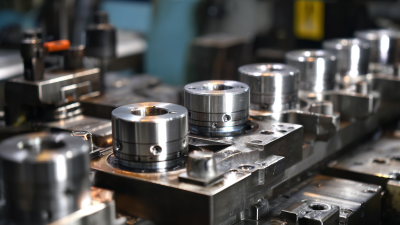

Tips for manufacturers considering brass forging include investing in advanced forging technologies, such as CNC machinery, which can significantly improve precision and reduce production times. Moreover, evaluating the alloy composition can lead to optimized performance: for instance, adding small amounts of lead can enhance machinability without compromising strength. Additionally, conducting regular quality control checks can ensure consistency in the finished products, ultimately resulting in higher customer satisfaction.

Implementing brass forging in production lines not only enhances product reliability but also supports sustainable practices. Forging utilizes less material waste compared to machining from solid blocks, with studies showing a reduction in excess material by up to 40%. Embracing brass forging thus represents a strategic move towards both efficiency and environmental responsibility in manufacturing.

In modern manufacturing, the choice of materials and fabrication methods significantly influences the efficiency, cost, and quality of the final products. When comparing brass forging parts to other metal fabrication techniques, several advantages become apparent. Brass forging offers superior strength and durability compared to methods like casting or machining, as the forging process aligns the grain structure of the metal, leading to enhanced mechanical properties. Additionally, brass components exhibit excellent corrosion resistance, making them suitable for various applications in industries such as aerospace, automotive, and plumbing.

Another key point of consideration is the versatility of brass forging. Unlike aluminum or stainless steel processes, which may require extensive finishing, brass can be efficiently forged into precise shapes with minimal material waste. This not only reduces production costs but also accelerates lead times, giving manufacturers a competitive edge in rapidly changing markets. As the U.S. metal forging market continues to evolve, understanding these comparative benefits helps businesses make informed decisions that leverage the unique qualities of brass while optimizing overall production processes.

Brass forging parts are increasingly gaining traction across various industries due to their durability, versatility, and the advanced manufacturing processes that have emerged in recent years. Industries such as aerospace, automotive, and plumbing have recognized the benefits of using brass components, particularly in applications requiring high corrosion resistance and strength. Recent trends in metal forging processes, including the integration of additive manufacturing, are transforming how these parts are produced, making them more efficient and cost-effective.

In terms of application, brass is notably utilized in the production of fittings and fixtures, thanks to its ability to withstand harsh environments while maintaining aesthetic appeal. For businesses looking to capitalize on the surging demand for forged and stamped goods—which is projected to reach significant market heights—investing in modern brass forging methods can offer a competitive edge.

**Tips:** When considering brass parts for your manufacturing needs, ensure you are sourcing from reputable suppliers that emphasize quality control in their forging processes. Additionally, staying informed about technological advancements, like the integration of additive manufacturing, can help optimize your production capabilities and efficiency. Finally, keep an eye on market trends, as the growing emphasis on smart factories could mean new opportunities for innovation and cost savings in brass part manufacturing.

The global brass market is poised for significant growth, with its size projected to expand from USD 6.5 billion in 2023 to a remarkable USD 21.08 billion by 2033. This impressive growth can largely be attributed to the industry's increasing focus on sustainability and cost efficiency, particularly in sectors like faucet manufacturing, which is expected to reach USD 58.30 billion by 2033. Brass forging parts are at the forefront of this transformation, offering manufacturers an economical choice without compromising on quality.

Tips for manufacturers looking to incorporate brass forging parts include evaluating the lifecycle costs associated with different materials. Brass, unlike other metals, can be recycled efficiently, which enhances both sustainability and overall cost-effectiveness. Furthermore, aligning with the trend of urbanization and the growing demand for smart technologies can further drive the adoption of brass products.

Investing in lead-free brass varieties not only complies with environmental standards but also appeals to a market increasingly aware of sustainability. With the demand for sustainable and efficient manufacturing processes on the rise, utilizing brass forging parts is a strategic choice for modern manufacturers looking to lead in innovation and responsible production.