Leave Your Message

-

Phone

-

E-mail

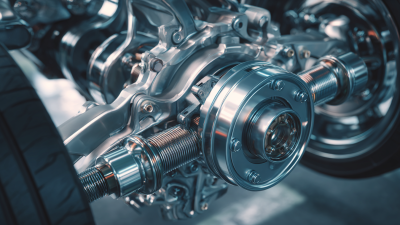

In the ever-evolving landscape of manufacturing, the importance of precision tools cannot be overstated, and among these, the Cold Heading Die stands out as a pivotal component in optimizing production efficiency. According to a recent report by Technavio, the global cold heading market is projected to grow by 4.3% annually, highlighting the increasing reliance on this technology in various industrial applications. This growth reflects the ongoing demand for cost-effective and high-quality manufacturing processes, particularly in automotive and aerospace sectors.

Industry expert Dr. Emily Ward, a leading authority in metal forming technologies, emphasizes the impact of Cold Heading Die on operational efficiency, stating, "The adoption of advanced Cold Heading Die techniques not only reduces material wastage but also enhances the overall quality of the end product." With its ability to produce complex shapes with minimal scrap, the Cold Heading Die significantly contributes to sustainable manufacturing practices, aligning with the industry's shift towards greener solutions.

As manufacturers look to streamline processes and improve productivity, understanding the top benefits of integrating Cold Heading Die into their operations becomes essential. From cost savings to enhanced product durability, the potential advantages are substantial, making it a focal point for companies aiming to stay competitive in 2025 and beyond.

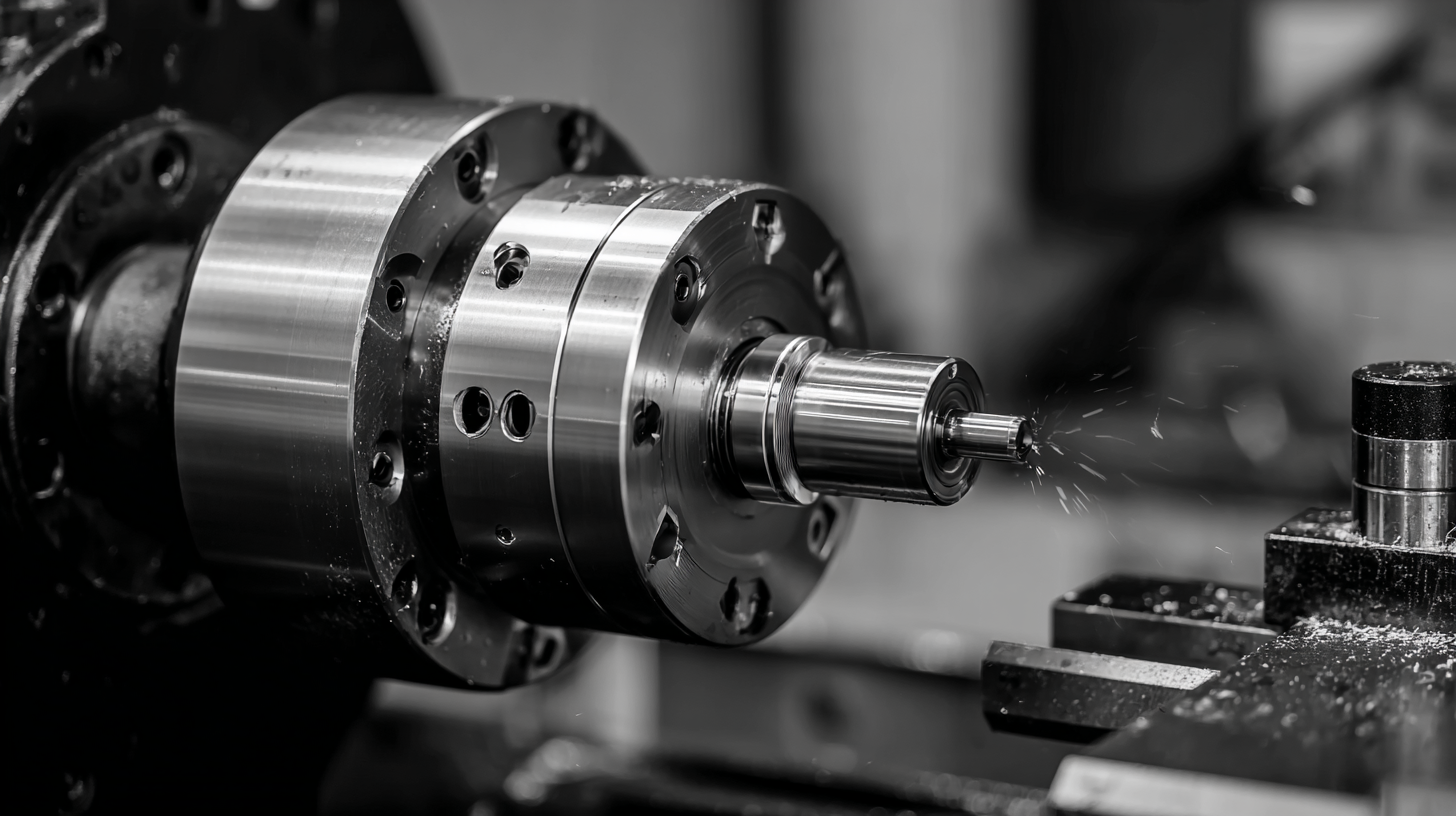

Cold heading die technology has significantly transformed precision manufacturing techniques, offering numerous advantages that enhance production efficiency and product quality. One of the primary benefits is the ability to produce complex shapes with minimal material waste. By using cold heading, manufacturers can create intricate geometries without extensive machining, thereby optimizing material usage and reducing costs.

Cold heading die technology has significantly transformed precision manufacturing techniques, offering numerous advantages that enhance production efficiency and product quality. One of the primary benefits is the ability to produce complex shapes with minimal material waste. By using cold heading, manufacturers can create intricate geometries without extensive machining, thereby optimizing material usage and reducing costs.

Moreover, cold heading processes lead to improved mechanical properties in the finished products. The cold working involved in heading enhances the material's strength through work hardening, resulting in components that can withstand demanding applications. This characteristic is particularly crucial in industries such as automotive and aerospace, where the reliability and durability of parts are paramount. Additionally, the precision achieved through cold heading die technology ensures that components meet tight tolerances, which is essential for maintaining the integrity of complex assemblies.

The cold heading process is revolutionizing manufacturing efficiency by streamlining production and reducing waste. This method utilizes high-pressure forging to transform metal into precise shapes without the need for extensive machining. By significantly minimizing material loss and energy consumption, cold heading emerges as a cost-effective option for manufacturers looking to enhance their operational efficiency.

In addition to improved material utilization, cold heading allows for rapid production rates. As the process requires fewer steps compared to traditional machining, cycle times are drastically reduced. This enables manufacturers to meet higher demand without sacrificing quality. Moreover, the production of components with precise tolerances enhances their functionality and performance, giving businesses a competitive edge in various industries. Through innovative cold heading techniques, manufacturers can achieve enhanced production efficiency while maintaining the integrity and reliability of their products.

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| High Material Utilization | Minimizes waste by utilizing metal effectively during the forming process. | Reduces raw material costs and maximizes yield. |

| Increased Production Speed | Allows for rapid processing, increasing the number of parts produced per hour. | Accelerates delivery times and boosts overall productivity. |

| Enhanced Dimensional Accuracy | Provides precise control over dimensions, reducing the need for secondary operations. | Increases consistency and quality of parts, decreasing rework time. |

| Lower Production Costs | Reduces cycle times and labor costs, leading to lower overall manufacturing expenses. | Increases profitability for manufacturers. |

| Versatile Applications | Can be used for producing a wide range of components in various industries. | Enhances adaptability to different production needs. |

| Reduced Need for Machining | Minimizes machining requirements by achieving near-net shape in the die. | Cuts down on machining time and costs significantly. |

| Improved Mechanical Properties | Cold heading enhances tensile strength and other physical properties of the material. | Leads to longer-lasting and more reliable components. |

| Environmentally Friendly | Produces less waste and consumes less energy compared to traditional methods. | Contributes to sustainable manufacturing practices. |

| Short Setup Times | Quick setups facilitate faster transitions between different production runs. | Maximizes operational efficiency and reduces downtime. |

| Consistent Quality | Automated processes ensure quality consistency across large production volumes. | Maintains customer satisfaction and minimizes defects. |

Cold heading dies are instrumental in enhancing cost-effectiveness within manufacturing processes. By utilizing these dies, manufacturers can significantly reduce material waste, as the cold heading process involves deforming metal at room temperature, transforming it into the desired shape without cutting. This minimizes scrap material, allowing companies to optimize their raw material usage and lower overall production costs. The precision and efficiency of cold heading also mean that fewer machining processes are required post-production, further decreasing expenses associated with labor and additional machinery.

Furthermore, the longevity and durability of cold heading dies contribute to increased profit margins. These dies are built to withstand the rigors of high-volume production, resulting in lower replacement rates compared to conventional shaping tools. This reliability allows manufacturers to maintain consistent output levels, ensuring that production schedules are met without the interruptions that can arise from equipment failures or the need for tool changeovers. Ultimately, the cost savings from reduced waste and increased operational efficiency translate to a healthier bottom line, reinforcing the value of investing in cold heading dies for manufacturing.

Cold heading techniques have revolutionized manufacturing processes by enhancing material strength and durability. This method involves deforming metal at room temperature, which allows for a uniform grain structure—resulting in improved mechanical properties. Unlike traditional methods, cold heading minimizes material wastage and energy consumption while producing components with outstanding tensile strength. The result is products that can withstand higher loads and resist wear over time, making them ideal for critical applications in various industries.

Additionally, cold heading contributes to the overall integrity of the components produced. By employing this technique, manufacturers can achieve precise dimensions and complex shapes without compromising the physical properties of the material. The cold working process introduces strain hardening, which increases the yield strength of the metals utilized. Consequently, components created through cold heading not only exhibit enhanced durability but also a longer lifecycle. As industries continue to prioritize efficiency and reliability, the adoption of cold heading dies becomes increasingly beneficial, providing a competitive edge in producing robust, high-quality products.

Cold heading die applications play a crucial role in streamlining complex component designs within manufacturing processes. By utilizing cold heading technology, manufacturers can produce intricate shapes and forms with remarkable precision. This method allows for the creation of complex geometries that would be difficult or impossible to achieve through conventional machining techniques. The capability to form materials at room temperature not only preserves their structural integrity but also reduces the risk of defects and ensures high-quality end products.

Additionally, the efficiency provided by cold heading dies significantly enhances production rates. Manufacturers can rapidly produce large volumes of parts with tight tolerances, minimizing the need for secondary operations. This not only saves time but also cuts costs, making it a preferred choice for industries seeking to optimize their manufacturing processes. The versatility of cold heading dies allows for the adaptation to various materials and design specifications, further expanding their applicability across different sectors, including automotive, aerospace, and electronics. As companies continue to innovate, cold heading die technology will play an increasingly important role in meeting the demands for complex and high-performance components.