Leave Your Message

-

Phone

-

E-mail

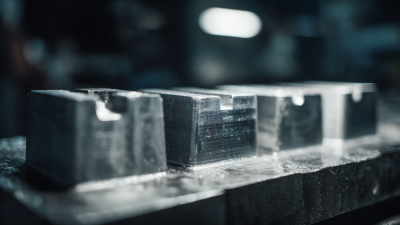

As the manufacturing industry evolves in 2025, the incorporation of advanced materials continues to drive efficiency and innovation. Among these materials, "Forged Aluminum Parts" stand out for their exceptional strength-to-weight ratio, making them a preferred choice across various sectors, including aerospace, automotive, and consumer goods. Industry expert Dr. Emily Carter, a leading metallurgist, emphasizes the transformative role of these components, stating, "Forged Aluminum Parts not only enhance performance but also reduce material waste, paving the way for a more sustainable manufacturing future."

The benefits of utilizing forged aluminum parts are increasingly recognized by manufacturers aiming to enhance product durability without compromising weight and overall efficiency. These parts are integral to lightweight design trends that are vital for modern applications, where performance and fuel efficiency are paramount. Moreover, advancements in forging technology have allowed for enhanced precision, further establishing forged aluminum parts as a key player in 2025's manufacturing landscape.

As industries continue to prioritize sustainability and innovation, the adoption of forged aluminum parts is expected to escalate. Their unique properties set the foundation for enhanced product design and improved lifecycle performance, affirming the importance of this material in the future of manufacturing.

In the modern manufacturing landscape, forged aluminum parts are gaining significant traction due to their exceptional strength-to-weight ratio and superior mechanical properties. According to a recent report by the Aluminum Association, the use of forged aluminum components in industries such as aerospace, automotive, and construction has experienced a remarkable growth rate, projected to reach a market value of approximately $85 billion by 2025. This rise is attributed to forging techniques that enhance the grain structure of aluminum, leading to increased durability and performance.

Moreover, forged aluminum parts offer notable advantages in terms of sustainability. The manufacturing process allows for efficient recycling of aluminum, resulting in reduced energy consumption and minimized waste. According to a study published by the International Aluminum Institute, recycling aluminum saves up to 90% of the energy needed to produce new aluminum from raw materials. This alignment with sustainable practices is particularly appealing for manufacturers looking to enhance their environmental credibility while adhering to increasingly stringent regulations regarding carbon emissions and material sourcing.

As industries evolve, incorporating forged aluminum components is not just a trend but a strategic move towards operational efficiency and sustainability.

Forged aluminum parts are becoming increasingly prominent in the manufacturing industry due to their exceptional combination of strengths and properties. One of the key attributes of forged aluminum is its outstanding strength-to-weight ratio. This characteristic makes it an ideal choice for sectors that require materials that can withstand significant stress while remaining lightweight, such as aerospace and automotive industries. The forging process enhances the material's integrity and resilience, resulting in components that are not only durable but also capable of performing optimally under various conditions.

Another significant property of forged aluminum is its excellent corrosion resistance. This makes it suitable for applications in harsh environments where exposure to moisture and chemicals is common. The ability to maintain structural integrity over time, even in challenging conditions, ensures that forged aluminum parts contribute to the longevity and reliability of the products they are used in. Furthermore, forged aluminum can be easily machined and welded, providing versatility in production and allowing for complex designs and structures that meet specific industrial needs efficiently.

In 2025, forged aluminum components are making significant strides across various sectors due to their exceptional strength-to-weight ratio and design flexibility. In the automotive industry, manufacturers are increasingly utilizing forged aluminum parts to enhance fuel efficiency while meeting stringent safety standards. These components provide the durability required for high-performance vehicles, enabling automakers to produce lighter cars without compromising on safety or structural integrity.

The aerospace sector is also witnessing a growing application of forged aluminum parts, where weight savings play a crucial role in operational efficiency. These components can withstand extreme conditions during flight while offering superior corrosion resistance. Additionally, the construction industry is capitalizing on forged aluminum for structural applications, such as in bridges and buildings, where load-bearing capabilities and lightweight properties are essential for innovative architectural designs. This trend underscores the versatility of forged aluminum, establishing it as a pivotal material in advancing manufacturing technologies across various fields in 2025.

The cost-effectiveness of forging aluminum parts in production has become increasingly prominent in the manufacturing industry as companies seek innovative ways to enhance performance while reducing expenses. In 2025, studies indicate that forged aluminum components can reduce material waste by up to 30% compared to traditional casting methods. This significant reduction not only minimizes material costs but also streamlines the overall production process, leading to lower labor costs and increased throughput. According to the Aluminum Association, utilizing forged aluminum can improve component strength and durability, reducing the likelihood of failures and the associated costs of replacements.

Moreover, the demand for lightweight materials in sectors like automotive and aerospace has driven the forging of aluminum parts into a competitive position within the market. A report by Deloitte estimates that the lightweighting strategies could save the automotive industry around $90 billion by 2025 through improved fuel efficiency and reduced emissions. As manufacturers turn to forged aluminum, the ability to produce complex shapes with minimal machining offers both time and cost savings. The combination of improved material properties and the efficiency of the forging process positions forged aluminum parts as a cost-effective solution for various applications, solidifying their role in the evolving landscape of modern manufacturing.

The sustainability and environmental impact of forged aluminum manufacturing have become key considerations in the 2025 manufacturing landscape. As industries increasingly prioritize environmentally friendly practices, forged aluminum stands out due to its high recyclability and lower carbon footprint compared to other materials. Forged aluminum parts can be recycled indefinitely without degradation in quality, thereby significantly conserving natural resources and reducing energy consumption during production. This closed-loop lifecycle not only minimizes waste but also supports the transition toward a circular economy, which is essential for sustainable industrial practices.

Furthermore, innovations in the forged aluminum manufacturing process have led to advancements that further reduce environmental impacts. Modern techniques have improved energy efficiency and minimized emissions associated with production. These advancements often involve utilizing renewable energy sources and optimizing manufacturing operations, leading to a notable decrease in greenhouse gas emissions. By adopting sustainable practices in forged aluminum manufacturing, companies can not only comply with increasing regulatory demands but also enhance their market competitiveness by appealing to eco-conscious consumers. This shift towards sustainability signals a transformative change in the manufacturing sector, positioning forged aluminum as a cornerstone of a greener future.