Leave Your Message

-

Phone

-

E-mail

In the manufacturing industry, the choice of materials can significantly affect product performance and durability. "Forged Aluminum Parts" are gaining popularity for various applications. As Joe Smith, a leading expert in metal fabrication, states, "Forged aluminum parts bring unmatched strength and versatility to any project." This sentiment echoes the growing trend towards lightweight materials that do not compromise on strength.

Forged aluminum parts are crafted through a process that enhances their structural integrity. This results in products that withstand extreme conditions without failure. Manufacturers often find that these parts lead to more efficient and reliable machinery. However, the decision to implement forged aluminum components should not be taken lightly.

Cost considerations can be challenging, leading some manufacturers to overlook the long-term benefits. Additionally, not all forged aluminum parts meet the same quality standards. Therefore, careful supplier selection is crucial. Overall, understanding the intricate balance of advantages and challenges associated with forged aluminum parts becomes essential for making informed manufacturing decisions.

Forged aluminum parts are becoming essential in modern manufacturing. Their ability to significantly reduce weight is a major advantage. Lighter components improve efficiency, leading to enhanced performance in various applications. Industries focused on aerospace and automotive greatly benefit from this feature. A lower weight can mean better fuel efficiency and reduced emissions.

Using forged aluminum has its challenges. For instance, the initial costs can be higher compared to other materials. Additionally, sourcing quality aluminum is crucial. Poor-grade materials can lead to structural weaknesses. However, the long-term benefits often outweigh these initial hurdles.

Tips: Consider the specific needs of your project. Analyze the weight reduction against potential costs. Testing different grades of aluminum can also help improve final outcomes. Make adjustments based on feedback from practical applications. Regularly review performance to ensure that benefits are maximized. This reflective practice is vital in a world where technology is constantly evolving.

Forged aluminum components stand out due to their remarkable strength and durability. These parts are created under high pressure from aluminum billets, resulting in a refined internal structure. This process enhances their mechanical properties, making them significantly stronger than cast aluminum. The increased strength ensures these components can withstand harsh conditions and heavy loads, offering reliability in various applications.

Durability is another key advantage of forged aluminum. This material can resist corrosion, which is vital in outdoor or industrial environments. Additionally, forged aluminum components can maintain their integrity under extreme temperatures. They also exhibit improved fatigue resistance, making them suitable for high-stress applications. Over time, many manufacturers have recognized that using forged aluminum can reduce maintenance costs.

However, the forging process can be resource-intensive. Some manufacturers may struggle with initial setup costs and the need for specialized equipment. There is also a learning curve involved when switching from traditional methods. Understanding these factors is crucial for companies considering this manufacturing technology. It's essential to evaluate the trade-offs before fully committing to forged aluminum parts.

| Benefit | Description | Example Application | Impact |

|---|---|---|---|

| Enhanced Strength | Forged aluminum parts possess a higher tensile strength compared to cast or extruded aluminum components. | Aerospace components | Increased safety and reliability in critical applications. |

| Improved Durability | These parts resist wear and tear better, extending their overall service life. | Automotive parts | Lower maintenance costs and increased time between replacements. |

| Weight Reduction | Forged aluminum components are lightweight, contributing to overall reduction in product weight. | Sports equipment | Improved performance and fuel efficiency in vehicles. |

| Corrosion Resistance | Special treatments can enhance the corrosion resistance of forged aluminum. | Marine applications | Increased lifespan of components in harsh environments. |

| Design Flexibility | Forging allows for complex shapes and designs that may not be achievable with other methods. | Custom tooling and jigs | Enhanced functionality tailored to specific applications. |

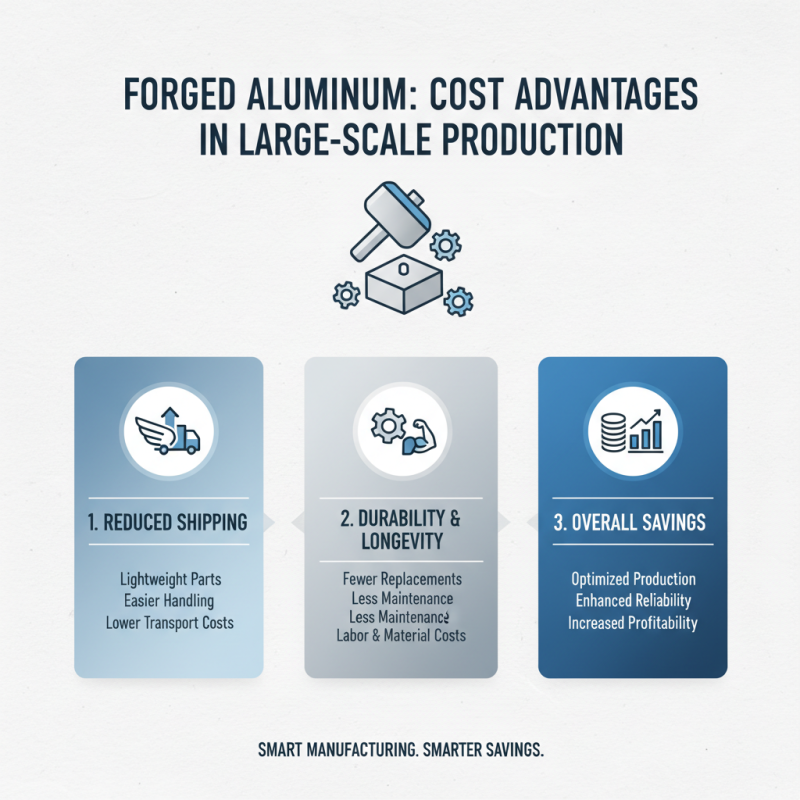

Forged aluminum parts offer clear cost advantages in large-scale production. They are lightweight, making shipping and handling easier. This reduces transportation costs significantly. In addition, their durability means fewer replacements are needed. Companies can save on material expenses and labor costs associated with maintenance and repairs.

However, the initial investment in forging technology can be high. Smaller manufacturers may struggle with this upfront expense. It may take time to see a return on investment. Despite these challenges, the long-term savings can be substantial. Businesses find themselves balancing short-term costs against the long-term gains.

The production process for forged aluminum parts is efficient. It generally has lower scrap rates compared to other methods. This means more usable material and less waste. That said, forging requires precision and expertise. Mistakes can lead to wasted resources and costly reworks. Companies must continuously evaluate their processes to ensure they are maximizing efficiency.

Forged aluminum parts offer significant advantages in manufacturing, particularly due to their improved corrosion resistance. Unlike steel or other metals, forged aluminum naturally forms a protective oxide layer when exposed to air. This layer acts as a barrier, preventing oxidation and deterioration. For many applications, this reduces the need for additional coatings or treatments, saving time and costs in production.

However, it's essential to note that not all aluminum alloys exhibit the same level of corrosion resistance. Some may still be prone to pitting or other forms of wear. Manufacturers should closely evaluate the specific alloy used to ensure it meets the necessary performance criteria. There are instances where users might overlook these details, leading to unexpected failures.

In environments with heavy exposure to moisture or chemicals, forged aluminum parts shine. They can endure harsh conditions that would quickly corrode other materials. Still, it's vital to monitor the maintenance of these parts. Regular inspections can help detect any early signs of wear or damage. These proactive measures can mitigate risks and enhance longevity in manufacturing applications.

Forged aluminum parts play a crucial role in both aerospace and automotive industries. These components offer high strength-to-weight ratios, which is vital for performance. For example, the aerospace sector often demands materials that can withstand extreme conditions while minimizing weight. According to a 2022 industry report, aluminum forgings can reduce vehicle weight by as much as 20%. This reduction in weight directly correlates to improved fuel efficiency.

In automotive applications, forged aluminum is increasingly popular for engine components and chassis parts. A study by the Aluminum Association indicated that using aluminum can enhance a vehicle's performance and lower carbon emissions. With stringent emissions standards, manufacturers must find innovative solutions. Forged aluminum not only addresses these demands but also provides long-term durability.

Tip: Consider using forged aluminum parts for projects requiring both lightweight and durable materials.

Still, challenges exist. The forging process can be costly. It requires specialized equipment and skilled labor. Manufacturers must evaluate the overall production process to ensure cost-effectiveness.

Tip: Always analyze the trade-offs between cost and performance when selecting materials for your designs.

This chart illustrates the top five benefits of using forged aluminum parts in manufacturing, rated on a scale of 1 to 10. The highest rating is for weight reduction and strength, making these parts highly valuable in aerospace and automotive applications.