Leave Your Message

-

Phone

-

E-mail

The cold forging die industry continues to evolve, driven by the need for efficiency and quality. Renowned expert Dr. Robert Lane explains, "Effective die design is the backbone of success in cold forging." His words resonate in an era where precision manufacturing defines competitive advantage.

Understanding cold forging die techniques is essential for optimal performance. These techniques influence material flow and shape accuracy. The selection of die materials impacts tool longevity. Moreover, cooling methods play a crucial role in maintaining die temperatures during high-speed processes.

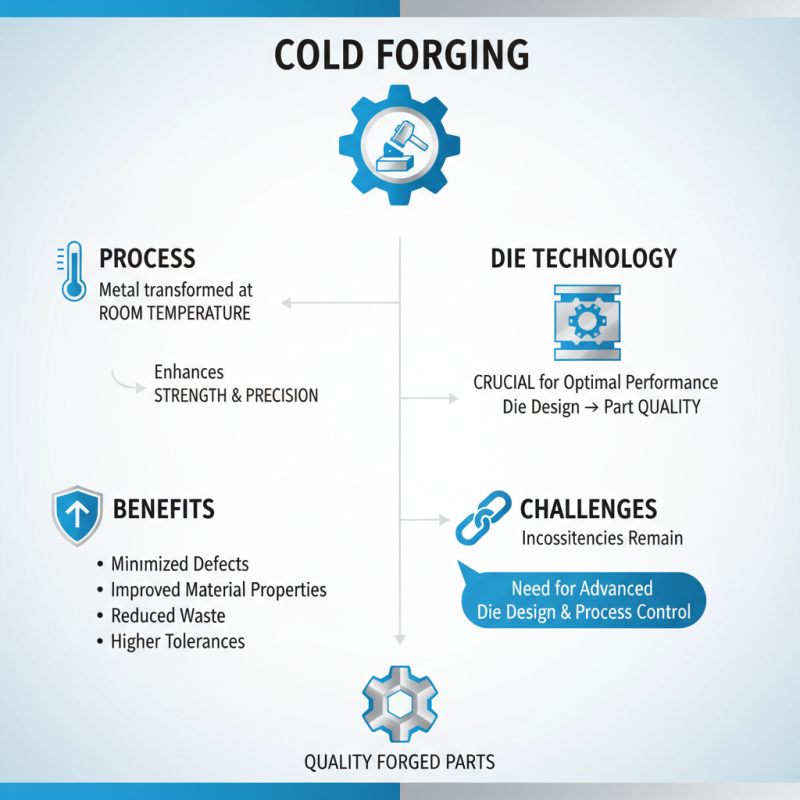

Despite advancements, challenges remain. Some designs still suffer from defects or manufacturing inconsistencies. There is always a need for improvements and a reevaluation of existing practices. Companies must be willing to reflect on past failures to maximize their innovation capabilities and the efficiency of cold forging die technology.

Cold forging is a widely adopted technique in the manufacturing industry, known for producing high-strength components efficiently. Understanding optimal die techniques is crucial for enhancing performance. A recent industry report indicates that nearly 40% of production defects come from die wear and misalignment. This highlights the need for precision in design and maintenance.

One effective technique is the use of specialized die materials. Tool steels with high hardness and wear resistance can significantly extend die life. Data shows that choosing the right material can reduce wear rates by up to 30%. However, the challenge lies in the cost and availability of these materials. Some manufacturers still opt for lower-quality dies, leading to unforeseen breakdowns.

Another impactful approach is the implementation of advanced computer simulations. These simulations can predict potential failure points in the die design. Research indicates that utilizing this technology can minimize trial-and-error processes by 50%. While many companies are adopting these innovations, ongoing staff training is often overlooked, which can hinder progress. Emphasizing staff skill development alongside technology can create a more robust approach to die performance.

Cold forging is a pivotal process in metal forming. It transforms metal at room temperature, enhancing strength and precision. Understanding die technology is crucial for optimal performance. The design of the die directly influences the overall quality of the forged parts. A well-designed die can minimize defects. However, many processes still struggle with inconsistencies.

Die materials play a vital role in this process. Hardened steel is commonly used, but it's not infallible. The choice depends on factors like cost, durability, and complexity. In some cases, dies wear out too quickly, leading to production delays. This indicates the need for better wear resistance and coating technologies.

Moreover, cooling techniques are essential. Many fail to recognize how temperature affects metal flow and die life. Ineffective cooling can result in uneven dies and poor part quality. Troubleshooting these issues requires careful observation and adjustment. Embracing innovative techniques can lead to significant improvements in cold forging outcomes. Understanding the nuances of die design and material selection is vital for success.

Cold forging is a precise manufacturing process. The performance of cold forging dies is influenced by several key factors. Material selection is critical. High-quality steel is often essential for durability. However, not all forms of steel are suitable for every application. Some may wear out quickly, leading to inconsistent part quality.

Die design plays a significant role. A well-designed die can reduce stress and improve flow. But, achieving the right balance between complexity and functionality is challenging. Miscalculations during the design phase may lead to increased rates of failure. Additionally, the cooling process after forging is vital. If not managed well, it could disrupt the die's integrity.

Maintenance routines impact performance too. Regular inspections help identify wear issues. Yet, many manufacturers overlook this step. Neglected dies can cause production delays. Operators must also be trained well. A lack of knowledge can result in improper handling. This, in turn, affects product quality and overall efficiency. Balancing these factors is essential for achieving optimal results in cold forging.

Cold forging die materials play a crucial role in the manufacturing process. Selecting the right one can significantly impact performance. Tool steel is among the most common materials used. It's durable and offers good wear resistance. However, tool steel can be brittle under certain conditions. This brittleness requires careful design and maintenance.

Another popular option is aluminum. Aluminum dies are lightweight and can withstand high impact. They are more flexible than steel. This flexibility can be advantageous during design changes. However, aluminum does not have the same lifespan as steel. This trade-off can lead to higher long-term costs.

Some manufacturers experiment with composite materials. These can provide a unique blend of properties. They might offer better thermal conductivity or reduced weight. Yet, the long-term durability of composites is often a concern. Finding the right balance between performance and longevity requires ongoing evaluation and refinement in material choices.

Cold forging is a complex process, and enhancing die durability and efficiency is crucial. Advanced techniques can significantly extend die life. Reports indicate that optimizing die materials can improve performance by 30%. High-strength steel alloys show better wear resistance and are gaining popularity in the manufacturing sector.

Tips: Regular maintenance is key. Inspect dies frequently for signs of wear. This prevents unexpected downtime and maintains production efficiency.

Surface treatments can also elevate die performance. Methods like nitriding increase hardness and resistance to wear. Some studies suggest that coated dies can reduce friction by up to 50%. These improvements can lead to cost savings in the long run.

Despite these advancements, challenges remain. Not every treatment is suitable for all applications. Improper selection can cause premature failure. Always evaluate environmental factors and material compatibility before implementation. Small adjustments can yield significant benefits.

Cold forging die technology plays a crucial role in enhancing the efficiency and durability of the cold forging process. Understanding the fundamentals of cold forging and the characteristics of various die materials is essential for optimizing performance. Key factors influencing the effectiveness of cold forging dies include material properties, design parameters, and operational techniques.

Advanced methods for improving die durability involve selecting appropriate materials and implementing specialized treatments that enhance their lifespan and resistance to wear. However, challenges like die wear, material flow issues, and design complexities frequently arise in the cold forging die design process. By addressing these common obstacles and exploring innovative solutions, manufacturers can significantly improve the operational effectiveness of cold forging dies, ultimately resulting in higher productivity and product quality.