Leave Your Message

-

Phone

-

E-mail

The aerospace industry is experiencing a significant transformation, with innovations in materials playing a crucial role in enhancing performance and efficiency. Among these advancements, Forged Aluminum Parts are at the forefront, offering a combination of strength, lightweight properties, and corrosion resistance essential for modern aircraft design. According to a report from MarketsandMarkets, the global aerospace materials market is projected to reach $25.9 billion by 2025, driven largely by the increasing demand for high-performance materials in airframe construction and engine components. Forged Aluminum Parts, known for their superior mechanical properties and reduced weight, are becoming indispensable in this competitive landscape. This blog will explore the five best innovations in Forged Aluminum Parts that are not only transforming manufacturing processes but also redefining the standards for safety, efficiency, and sustainability in the aerospace sector.

Innovative forged aluminum parts are significantly transforming the aerospace industry by enhancing design efficiency and contributing to sustainability. As the aerospace market continues to expand, projected to reach USD 15152.77 million by 2032, manufacturers are increasingly turning to advanced materials like forged aluminum. These lightweight components not only lower fuel consumption and emissions but also improve the overall performance and durability of aircraft.

The rise of metal additive manufacturing further complements the innovations in forged aluminum. This technology allows engineers to create complex geometries that were previously unachievable with traditional processes, leading to reduced material waste and enhanced functionality of aero engines. Additionally, initiatives aimed at increasing circularity in the aluminum supply chain are gaining momentum, as companies focus on recycling and reusing materials from decommissioned aircraft, aligning with global sustainability goals and reducing the environmental impact of aerospace production. Such advancements not only optimize performance but also promote a more sustainable future for the industry.

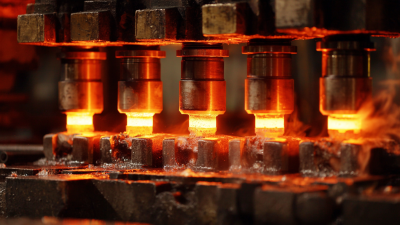

The aerospace industry is undergoing a significant transformation with the introduction of cutting-edge manufacturing techniques in forged aluminum components. Innovations such as additive manufacturing and advanced heat treatment processes have redefined the capabilities of aluminum parts, enhancing their strength-to-weight ratio. According to a report by the Global Aluminum Forging Market, the demand for lightweight materials in aerospace applications is projected to grow by over 5% annually, reflecting the industry's shift towards more efficient and sustainable manufacturing solutions.

One standout advancement is the implementation of precision forging technologies, which allows manufacturers to achieve tighter tolerances and superior mechanical properties in aluminum components. This approach not only improves component performance but also reduces waste during production. A study from the Aerospace Industries Association indicates that leveraging forged aluminum parts can result in weight savings of up to 30%, significantly impacting fuel efficiency and overall aircraft performance. As aerospace companies continue to adopt these innovative techniques, the future of aircraft design looks promising, revolving around the undeniable benefits of high-quality forged aluminum parts.

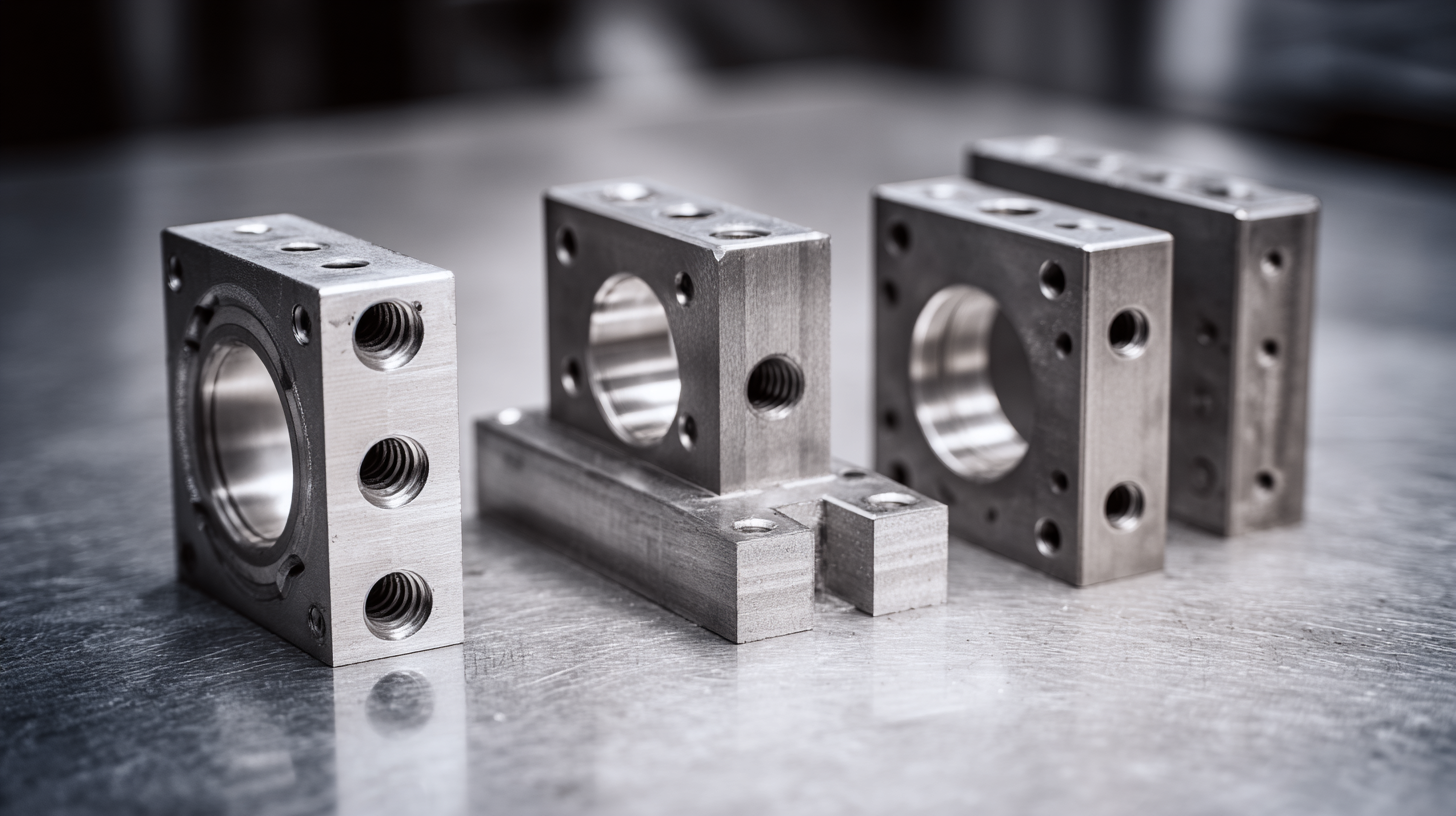

The aerospace industry is continuously evolving, with innovations in forged aluminum parts playing a pivotal role in reducing weight and enhancing overall performance. Recent studies indicate that approximately 20-30% of the total weight of an aircraft can come from its structural components. By utilizing advanced forged aluminum technologies, manufacturers can reduce this weight significantly. For instance, the implementation of forged aluminum, with its superior strength-to-weight ratio, has been shown to decrease part weight by up to 30% compared to traditional casting methods.

Moreover, these innovations also improve performance metrics, contributing to fuel efficiency and operational cost savings. According to a report by the International Air Transport Association, shifting to lightweight materials like forged aluminum can lead to fuel savings of about 1-2% per flight. This reduction might seem small, but it translates into substantial cost savings across an airline’s fleet over time. As the aerospace sector continues to seek sustainable solutions, the adoption of forged aluminum technologies underscores a promising pathway towards enhanced performance and reduced environmental impact.

The aerospace industry is continuously evolving, with a strong emphasis on safety and reliability. Forged aluminum parts have emerged as pivotal components in this transformation, offering significant improvements in strength, weight, and resistance to fatigue. By utilizing advanced forging techniques, manufacturers can produce aluminum components that not only meet but often exceed the rigorous safety standards dictated by industry regulations. These innovations ensure that aircraft can withstand extreme conditions, enhancing the overall durability and safety of the aircraft.

One of the key benefits of forged aluminum parts is their ability to reduce overall aircraft weight without compromising structural integrity. Lighter airplanes consume less fuel, leading to cost savings and lower emissions, which aligns with current environmental goals of the aerospace sector. Moreover, the superior mechanical properties of forged components mean that they are less likely to fail under stress, further improving safety margins. The integration of such innovations reflects a commitment to enhancing passenger safety and operational reliability, setting new benchmarks for aerospace manufacturing.

The aerospace industry is undergoing a significant transformation with the adoption of sustainable practices in the production of forged aluminum parts. As environmental concerns rise, manufacturers are increasingly focusing on reducing their carbon footprint and waste during the aluminum forging process. This shift not only benefits the planet but also aligns with the growing consumer demand for greener technologies in aviation.

Innovations in the production techniques of forged aluminum are at the forefront of this sustainable movement. Advanced recycling methods have emerged, enabling the reuse of aluminum scrap and reducing the reliance on virgin materials. Furthermore, companies are investing in energy-efficient machinery and practices that minimize energy consumption while maximizing output. These efforts contribute to a more sustainable supply chain, essential for meeting the projected growth in the global casting and forging market, which is anticipated to expand from USD 187.38 billion in 2025 to USD 260 billion by 2033.

By prioritizing eco-friendly strategies, the aerospace sector is not only enhancing the performance and durability of forged aluminum parts but also making a commitment to a more sustainable future. This commitment reflects a broader trend towards sustainability, paving the way for innovations that will redefine the industry landscape in the years to come.