Leave Your Message

-

Phone

-

E-mail

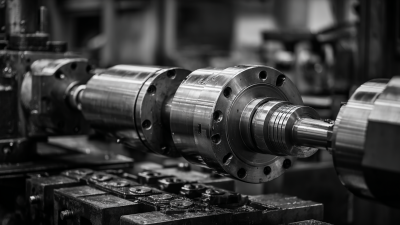

The efficiency of forging machine parts is critical to the overall productivity and profitability of manufacturing operations. According to a 2022 report by the International Energy Agency (IEA), optimizing machine performance can enhance productivity by up to 30% and significantly reduce energy consumption. As industries aim for sustainability, ensuring that forging machines operate at peak efficiency not only minimizes downtime but also leads to substantial cost savings. Implementing a comprehensive maintenance checklist is essential for identifying and addressing potential issues before they escalate. This blog will explore the top strategies for maintaining forging machine parts efficiency, providing insights into best practices that can be adopted across various manufacturing sectors to enhance operational effectiveness and ensure long-term reliability.

Maintaining the efficiency of forging machine parts is crucial for optimizing production processes and ensuring high-quality output. Several key factors influence this efficiency, including proper maintenance, the quality of raw materials, and operator training. Keeping machines well-maintained not only extends their lifespan but also minimizes downtime, allowing for smoother operations.

One important tip is to establish a regular maintenance schedule that includes inspections and servicing of all moving parts. This can help identify wear and tear early, reducing the risk of unexpected failures. Another essential aspect is sourcing high-quality raw materials, as impurities can affect the forging process and the final product’s integrity. Operators should also receive comprehensive training to understand machine functions and handle equipment effectively.

In addition, monitoring operational parameters such as temperature and pressure can greatly impact forging efficiency. Adjusting these parameters based on real-time data can help optimize the forging process, leading to better product quality and reduced waste. By focusing on these factors, manufacturers can significantly enhance the performance of their forging machines.

Regular maintenance routines are vital for boosting the performance of forging machine parts. Scheduled inspections, lubrication, and component adjustments can significantly enhance the efficiency of machinery. By routinely checking and replacing worn-out parts, operators can prevent unexpected breakdowns, ensuring smoother operations and reducing downtime. Incorporating a structured maintenance schedule not only prolongs the life of the equipment but also improves the overall productivity of the manufacturing process.

In addition to physical checks, software updates and performance monitoring should also be integral to regular maintenance. Implementing the latest technologies can optimize the equipment's functionality, allowing for real-time performance tracking. This proactive approach helps identify potential issues before they escalate, maintaining high efficiency levels and promoting consistent output quality. Investing time and resources into a comprehensive maintenance routine ultimately pays off, as it keeps forging equipment running at peak performance and minimizes costly repairs.

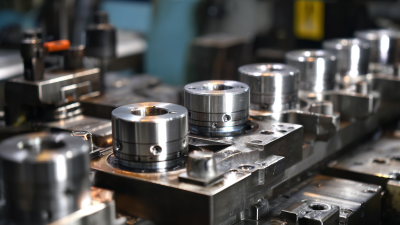

When it comes to maintaining the efficiency of forging machine parts, lubrication and cooling are critical elements that can significantly affect performance and longevity. Proper lubrication ensures that moving components function smoothly, reducing wear and tear, while effective cooling prevents overheating during the forging process. Utilizing high-quality lubricants that are specifically designed for the demands of forging operations can enhance the life of the machinery and improve product quality.

Recent advancements in cooling technologies, such as oil-cooled electric drive systems used in various automotive applications, highlight the importance of efficient heat management in mechanical operations. These innovative systems not only maintain optimal operating temperatures but also increase energy efficiency. When applied to forging machines, similar cooling solutions can be instrumental in preserving the integrity of machine parts and ensuring consistent production rates. By integrating advanced lubrication and cooling practices, manufacturers can optimize performance and achieve higher levels of productivity in their forging operations.

| Dimension | Best Practice | Frequency | Notes |

|---|---|---|---|

| Lubrication System | Regular oil changes | Every 500 hours | Use recommended oil grade |

| Cooling System | Inspect coolant levels | Daily | Top up as necessary |

| Filtration System | Replace filters | Every 1000 hours | Check for clogs |

| Temperature Monitoring | Regular temperature checks | Every shift | Ensure within safe range |

| Equipment Cleanliness | Routine cleaning | Weekly | Prevent buildup of debris |

Maintaining the efficiency of forging machine parts is crucial for maximizing production and minimizing downtime. Common issues such as wear and tear, improper lubrication, and alignment problems can greatly affect the performance of these machines. Regular inspections and preventative maintenance are key to identifying and addressing these issues before they escalate.

One important tip is to implement a diligent lubrication schedule. Proper lubrication reduces friction and wear on moving parts, enhancing machine longevity. Additionally, ensure that all lubrication points are easily accessible during maintenance checks. Consider using synthetic oils for better performance under extreme conditions.

Another common issue is misalignment of machine parts, which can lead to uneven wear and lower product quality. To mitigate this, conduct regular alignment checks using laser alignment tools. This practice not only improves the machine’s efficiency but also ensures that product tolerances are consistently met. By focusing on these critical areas, forging operations can achieve greater efficiency and reliability in their production processes.

In the modern manufacturing landscape, upgrading technology through automation is vital for enhancing forging efficiency. Automated systems streamline production processes, reduce manual labor, and significantly improve the accuracy of forged parts. By incorporating advanced robotics and control systems, manufacturers can achieve consistent quality while minimizing production time. This shift not only boosts productivity but also leads to cost savings over time.

Tip 1: Invest in training your workforce to effectively use new automated systems. Skilled operators can maximize the potential of automation, ensuring that machines run smoothly and adjustments are made swiftly when necessary.

Moreover, implementing smart technology, such as IoT devices, allows for real-time monitoring of forging processes. These systems can detect anomalies and recommend adjustments before small issues escalate into larger problems. By adopting predictive maintenance strategies, companies can prevent costly downtime and extend the lifespan of machine parts.

Tip 2: Regularly evaluate your automation setup to identify areas for improvement. A proactive approach to technology upgrades can further enhance efficiency and keep your operation competitive in the fast-evolving manufacturing sector.