Leave Your Message

-

Phone

-

E-mail

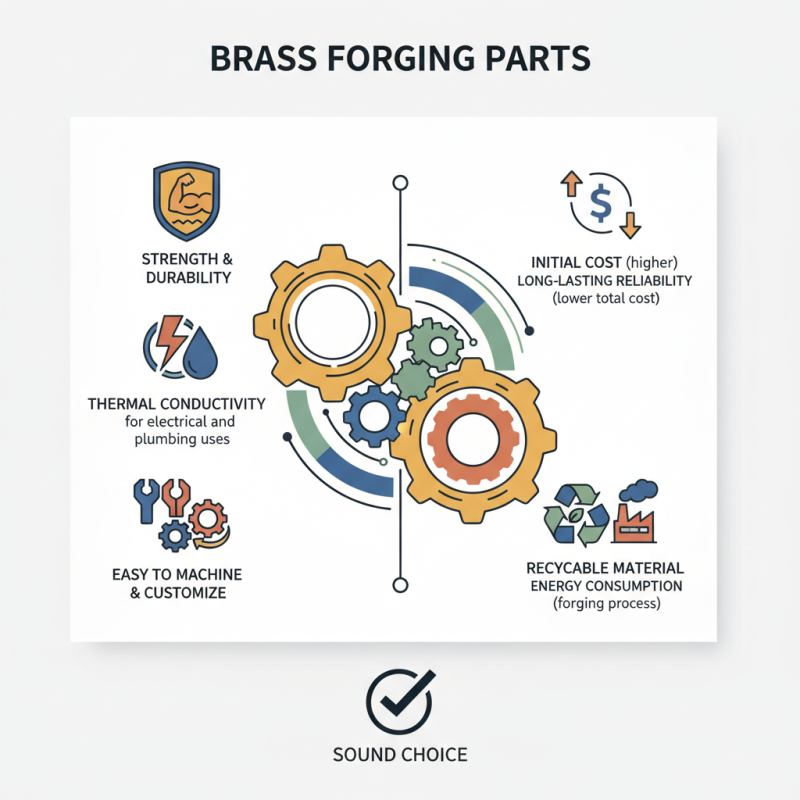

Brass forging parts offer exceptional advantages for various manufacturing applications. These components are known for their strength and durability. They perform well under stress and resist corrosion, making them ideal choices. Manufacturers appreciate the precision that forging provides. There are no added weaknesses from welding or casting. Thus, the integrity of brass remains intact.

In many industries, the choice of materials can make or break a project. Brass forging parts stand out due to their thermal conductivity. This feature is essential in electrical and plumbing applications. Additionally, manufacturers find these parts easy to machine and customize. However, the initial cost may give some pause.

Exploring brass forging might raise questions about sustainability. While brass is recyclable, the forging process consumes energy. It's essential to weigh the benefits against the environmental impact. Ultimately, brass forging can be a sound choice. It aligns performance needs with reliability for long-lasting manufacturing solutions.

Brass is a preferred material in the manufacturing industry. Its unique properties make it ideal for forging parts. Brass, an alloy of copper and zinc, offers excellent machinability and durability. The combination of these metals enhances strength while maintaining a lightweight profile. This unique balance allows for intricate designs without compromising performance.

Forged brass parts exhibit superior resistance to wear and corrosion. This durability extends the lifespan of components in harsh environments. However, some may overlook the importance of proper heat treatment. Without this step, even brass can become brittle. This is a critical consideration during the forging process. It highlights the need for manufacturers to pay close attention to their methods.

Additionally, brass offers excellent thermal and electrical conductivity. This makes it suitable for various applications like fittings and valves. However, issues can arise if incorrect alloy ratios are used. Even small deviations can impact performance. Understanding the nuances of brass forging is essential for successful outcomes in manufacturing.

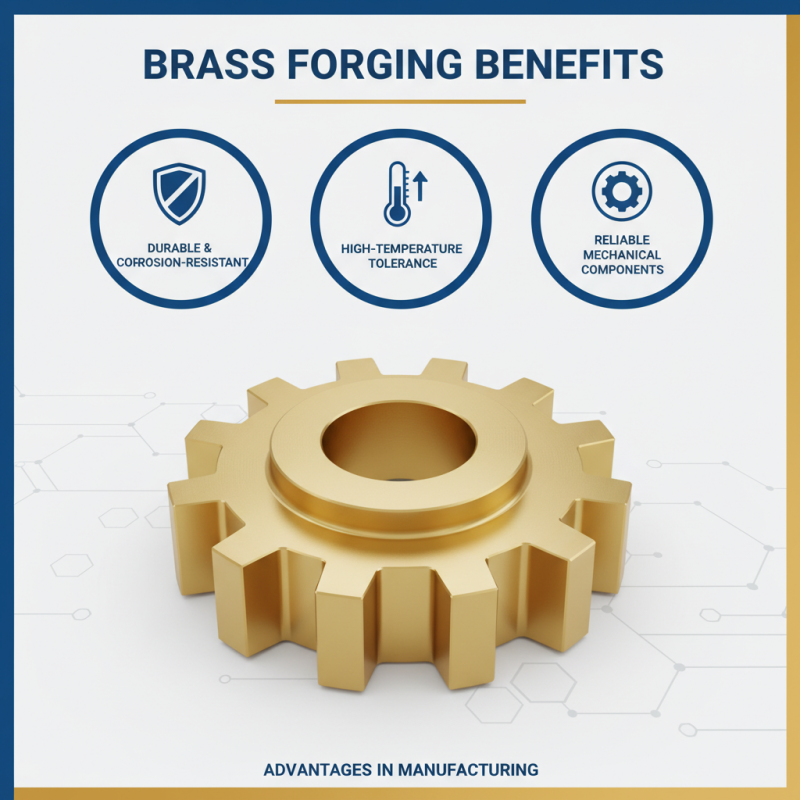

Brass forging parts have gained popularity in manufacturing. This is due to their unique benefits. Brass is durable and resistant to corrosion. It performs well in various environments, which makes it ideal for many applications. Furthermore, brass can withstand high temperatures. This enhances its reliability in mechanical components.

Choosing brass forging can save costs in the long run. The strength of forged parts reduces the need for replacements. Moreover, the precision of the forging process ensures minimal waste. This efficiency can improve your bottom line.

Tips: When selecting brass forging parts, consider their applications carefully. Evaluate the environment in which they will be used. Always check for certifications or quality standards. It might seem trivial, but overlooking details can lead to larger issues. A small mistake can disrupt production.

In manufacturing, the choice of materials is crucial. While brass offers many advantages, it is essential to weigh your options. Assess the specific requirements of your project. Are there alternatives that might fit better? Emphasizing quality over quantity can lead to better outcomes.

Brass forging parts are gaining attention in manufacturing. They are often compared to steel and aluminum. According to industry reports, brass offers improved malleability and corrosion resistance. This makes it suitable for applications in marine and plumbing sectors.

Steel has high strength yet lacks the corrosion resistance of brass. In harsh environments, steel can rust, leading to increased maintenance costs. Aluminum is lightweight but may not provide the same durability. Moreover, brass can withstand higher temperatures than aluminum, making it advantageous for certain applications.

However, the cost of brass forging parts can be a concern. They may be pricier than their aluminum counterparts. Some manufacturers hesitate to make the switch. Yet, the longevity of brass often offsets initial costs. For example, brass components can last over a decade with proper use. Manufacturers need to weigh these factors carefully.

Brass forged parts find extensive applications across various industries. The automotive sector utilizes these components for making durable, lightweight parts. Brass offers excellent corrosion resistance, which is essential in vehicles subjected to diverse climates. According to a 2022 report from the Automotive Industry Association, brass parts can reduce weight by up to 30% compared to their steel counterparts.

In the plumbing industry, brass fittings and valves are commonly forged. The material’s strength and thermal conductivity make it ideal for high-pressure applications. A 2021 study indicated that over 70% of plumbing systems in commercial buildings include brass components. This highlights the importance of brass in ensuring reliability and longevity in water supply systems.

Moreover, the electronics industry benefits from brass forged parts. These components are used in connectors and switches due to their excellent electrical conductivity. A market analysis estimated that the demand for brass in electronics will grow by 5% annually through 2025. While brass has many advantages, its cost can be a concern. Manufacturers must weigh these factors carefully when choosing materials for their production lines.

| Industry | Application | Advantages of Brass Forged Parts |

|---|---|---|

| Automotive | Connectors, valves, and fittings | Corrosion resistance and durability |

| Aerospace | Components in control systems | High strength-to-weight ratio |

| Electronics | Connectors and housings | Excellent electrical conductivity |

| Plumbing | Valves, fittings, and faucets | Good resistance to dezincification |

| Marine | Keeping components and fittings | Resistance to seawater corrosion |

When selecting brass forging parts, several key considerations come into play. The specific application is crucial. Different industries demand different properties from brass, such as strength, corrosion resistance, or aesthetic appeal. The exact requirements can vary widely based on whether parts are for plumbing, automotive, or aerospace.

Another factor is the manufacturing process itself. Brass forging can deliver high precision and strength. It often results in parts with superior mechanical properties compared to cast counterparts. However, the skill level of the workforce and the quality control measures also matter. Inconsistent practices can lead to subpar products. Always inspect samples for dimensional accuracy.

Lastly, consider the cost versus value equation. While high-quality brass may be more expensive, it often leads to longer-lasting products, saving money in the long run. This consideration is often overlooked. Companies may choose cheaper options without analyzing the potential hidden costs. Evaluate your choices carefully. The right selection can significantly impact efficiency and performance.