Leave Your Message

-

Phone

-

E-mail

When it comes to manufacturing, choosing the right materials is crucial. Forged Aluminum Parts stand out as a preferred option in various industries. Renowned expert Dr. Emily Johnson states, "Forged Aluminum Parts combine strength and lightweight properties, making them ideal for performance applications."

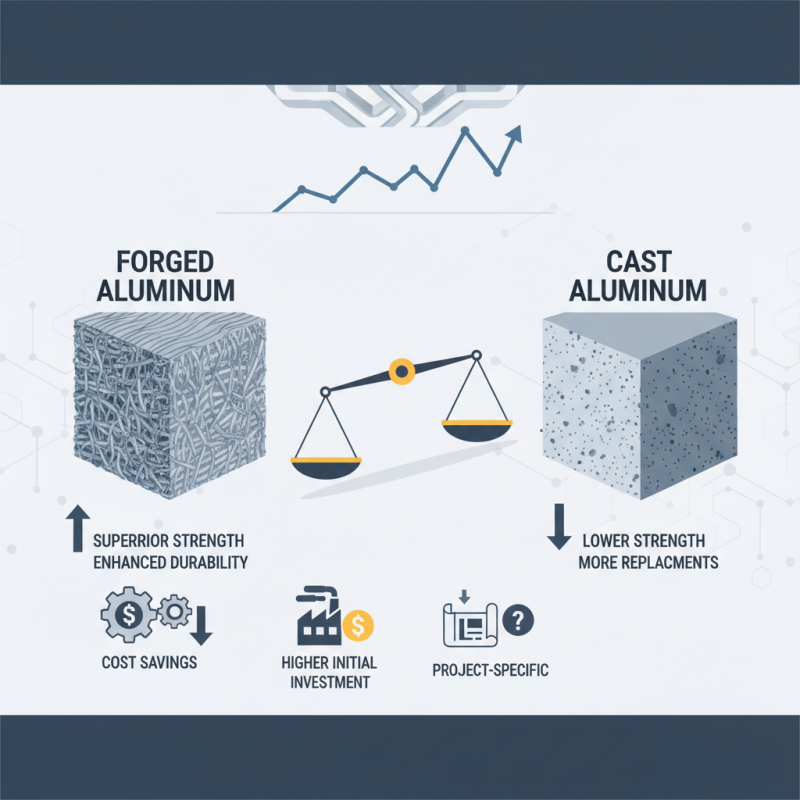

The forging process enhances the material's density. This results in superior strength compared to cast aluminum. Many manufacturers are realizing the benefits of this. Enhanced durability means fewer replacements and repairs. This can lead to significant cost savings over time.

However, it's important to consider potential downsides. The initial investment in forged parts can be higher. Not all manufacturing processes suit forged aluminum. Therefore, evaluating each project's unique requirements is essential. Forged Aluminum Parts may not always be the perfect solution, but their advantages are hard to overlook.

Forged aluminum parts are gaining popularity in various manufacturing applications. These components are created by shaping aluminum under high pressure. This process enhances the material's strength and durability. This is a key characteristic that sets forged parts apart from others. The final products often exhibit excellent fatigue resistance, making them suitable for demanding environments.

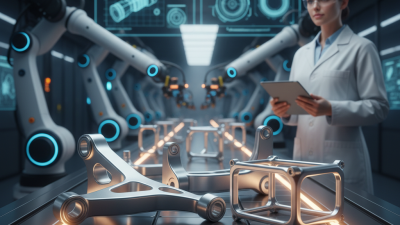

Another important characteristic is their lightweight nature. Forged aluminum parts have a great strength-to-weight ratio. This means they can support heavy loads without adding excessive weight. Such features are crucial in industries like aerospace and automotive. However, a downside can be the initial cost. While they are more expensive to produce, the long-term benefits often justify the investment.

Manufacturers need to weigh their options carefully. Forged parts may not be necessary for all applications. Some processes could lead to waste if not carefully evaluated. It’s essential to analyze the specific requirements before deciding on forged aluminum parts. The advantages are clear, but they come with their own set of complexities.

Forged aluminum parts offer distinct advantages in manufacturing applications. Their strength-to-weight ratio is impressive. This means that products are lightweight yet durable. Engineers often prefer these components for automotive, aerospace, and other high-performance fields. The forging process enhances the metal's internal structure, resulting in superior mechanical properties.

The ability to withstand high stress is crucial. Forged aluminum parts resist fatigue better than cast or machined options. They can endure harsh conditions without significant wear, making them ideal for demanding environments. Additionally, these parts exhibit excellent corrosion resistance. This quality extends the lifespan of products, reducing maintenance costs over time.

However, there are some challenges to consider. The initial investment in forging equipment can be high. Smaller manufacturers might hesitate due to costs. Also, the design flexibility is limited compared to other methods. Complex shapes may require alternative approaches. Striking a balance between performance and cost-effectiveness is essential for successful manufacturing.

| Advantage | Description | Applications |

|---|---|---|

| Strength | Forged aluminum parts have higher strength-to-weight ratios compared to other materials. | Aerospace, automotive components, structural applications. |

| Durability | Excellent resistance to wear and tear, leading to longer service life. | Heavy machinery, industrial equipment. |

| Corrosion Resistance | Natural resistance to rust and corrosion, suitable for harsh environments. | Marine applications, outdoor structures. |

| Lightweight | Significantly lighter than steel, improves fuel efficiency in vehicles. | Transportation, aerospace engineering. |

| Versatility | Can be used in a wide range of manufacturing processes and applications. | Electronics housing, sports equipment, medical devices. |

When manufacturing components, the choice of material is critical. Forged aluminum stands out against other materials like cast aluminum and steel. It offers superior strength-to-weight ratios. This means parts are lighter yet stronger, which is invaluable in industries like aerospace and automotive. However, it’s not without challenges. Forged aluminum can be more expensive and requires specialized equipment.

Comparing forged aluminum to cast alternatives, the latter may be easier to produce. Cast aluminum is good for intricate shapes and designs. Yet, it often lacks the durability of forged parts. Steel, while robust, is heavier and can lead to increased operational costs. The decision hinges on specific applications. Forged aluminum is ideal for high-stress environments, but it demands precise engineering. Not every manufacturer can meet these standards. Reflecting on these factors is essential for better outcomes.

Forged aluminum parts are increasingly popular across various industries due to their impressive strength-to-weight ratio. The aerospace sector, for example, relies on these parts for aircraft components. They offer durability and performance while keeping weight low. This is crucial for fuel efficiency and safety in aviation.

Another key application lies in automotive manufacturing. Forged aluminum components are ideal for engine parts and chassis applications. They withstand high stress while providing excellent performance. Moreover, the cycling industry also benefits. Bicycle frames made from forged aluminum are lightweight and robust, enhancing the rider’s experience.

However, there are challenges. Forging requires precise techniques and skilled labor. The initial cost can be higher compared to other methods. Companies must weigh quality against budget constraints. There's often pressure to innovate quickly, but taking the time for research ensures the right choices are made. Balancing these factors is essential for success in using forged aluminum parts.

When considering forged aluminum for your manufacturing project, a few key factors stand out. The weight-to-strength ratio of forged aluminum is impressive. This material is lightweight yet strong, making it ideal for many applications. However, it’s essential to evaluate the specific needs of your project. Will the finished product need to withstand high stress or extreme conditions?

Cost efficiency is another crucial factor. Forged aluminum parts can be more expensive initially, yet their durability often leads to lower maintenance costs. You should weigh the long-term benefits against the short-term budget constraints. At times, companies neglect to account for these expenses, leading to larger issues down the line.

Quality and precision play significant roles as well. The forging process allows for tighter tolerances and superior surface finishes. But not every manufacturer achieves the same level of quality. Researching suppliers and understanding their capabilities is vital. Often, the quest for the lowest price can overlook quality assurance, which can be detrimental. Each of these factors deserves careful consideration to ensure the best outcome for your project.