Leave Your Message

-

Phone

-

E-mail

In today's competitive industrial landscape, selecting the optimal Hot Forging Part is crucial for enhancing operational efficiency and product durability. According to a recent market analysis from Grand View Research, the global hot forging market is expected to reach USD 63.83 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.4%. This growth is driven by an increasing demand for lightweight and high-strength components in various sectors, including automotive and aerospace.

However, the success of any production process hinges on choosing the right forging part that meets specific operational requirements, material properties, and cost considerations. With myriad options available, understanding the factors that influence the selection process is imperative for manufacturers aiming to optimize performance and minimize production costs.

This guide will explore essential criteria and expert insights to help you navigate the complexities of selecting the ideal Hot Forging Part for your industrial applications.

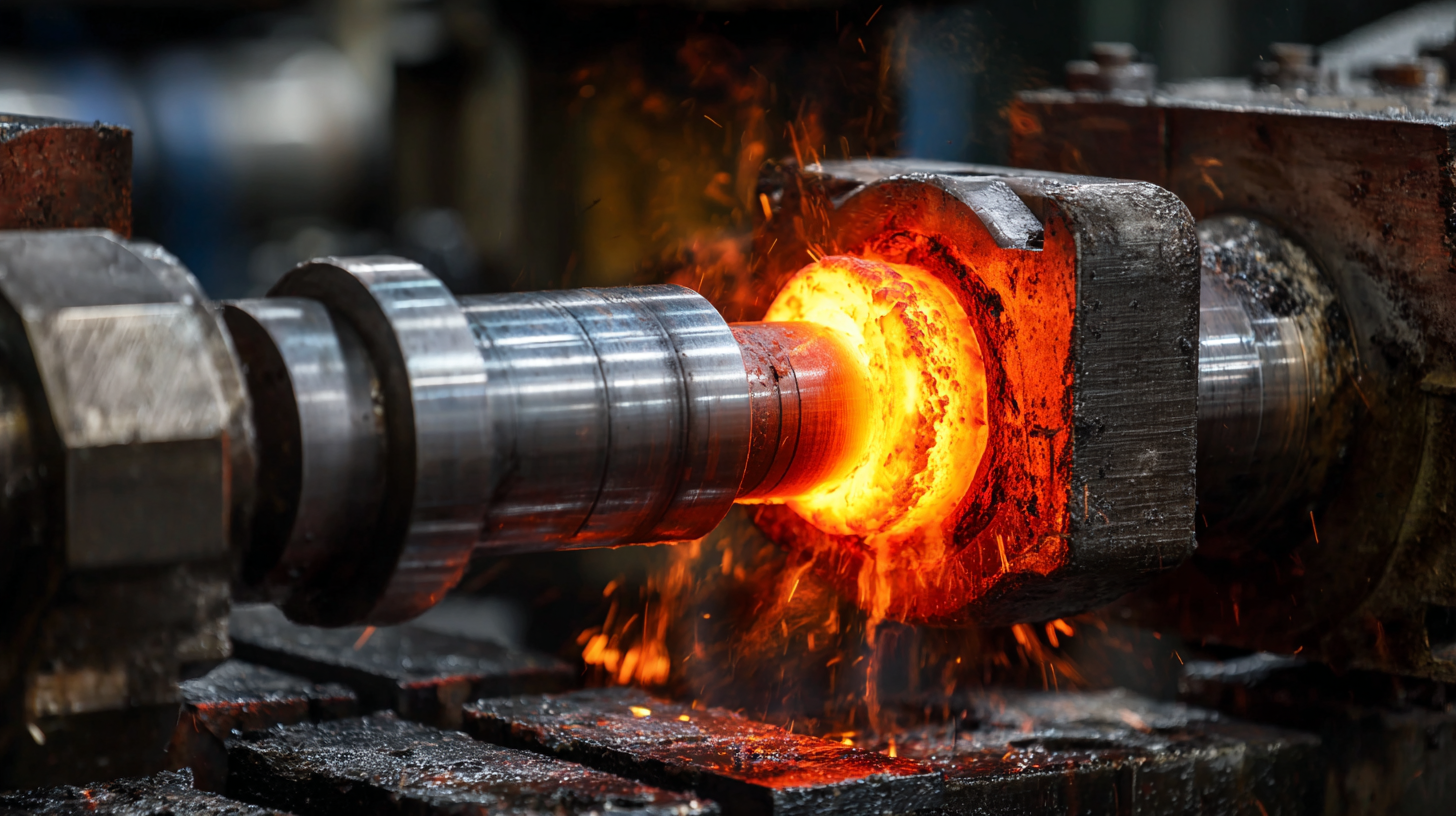

Hot forging is a manufacturing process that shapes metal by heating it to a high temperature and applying pressure. This technique enhances the mechanical properties of metals, making them stronger and more durable, which is crucial for various industrial applications. Industries like automotive, aerospace, and heavy machinery rely on hot forging for producing components that need to withstand high stress and strain.

When selecting the right hot forging parts, it’s essential to consider the specific industrial application and the material properties required. Different metals react differently to the hot forging process, which influences the final product's performance. For instance, steel is commonly used for its strength and versatility, while aluminum is favored for its lightweight and corrosion resistance. Understanding the unique demands of your application will guide you in choosing the most suitable forging method and material.

**Tip:** Collaborate with your supplier to discuss your project requirements in detail. They can provide valuable insights into the best materials and forging techniques available.

**Tip:** Always request samples or prototypes of hot forged parts before making large orders. This ensures that the components meet your quality standards and fit seamlessly into your production line.

When selecting the right hot forging part for industrial applications, several key factors must be considered to ensure optimal performance and durability. One important consideration is the material composition, as advanced lightweight materials like aluminum and high-strength steel are becoming increasingly popular in industries such as automotive. Recent reviews highlight the potential of these materials to enhance vehicle performance while reducing weight, ultimately contributing to better fuel efficiency and lower emissions.

Another critical aspect involves the understanding of the forging process parameters, particularly for materials like titanium alloys. Research indicates that nonisothermal forging processes can help optimize the mechanical properties while minimizing residual stresses, which can otherwise lead to component failure. For instance, studies on the Ti-6Al-4V alloy have demonstrated significant improvements in efficiency and product quality through multi-objective optimization, showcasing that the right combination of temperature and force can enhance the forging results significantly.

In addition to material and process specifications, in-process monitoring strategies are essential to maintain quality control throughout the forging process. Techniques that measure key variables such as temperature and deformation provide insights that can lead to better decision-making and adjustments in real-time, ultimately yielding parts that meet the rigorous demands of modern industrial applications.

| Material Type | Tensile Strength (MPa) | Ductility (%) | Applications | Cost (USD/kg) |

|---|---|---|---|---|

| Carbon Steel | 400-600 | 15-30 | Automotive, Machinery | 2.5 |

| Alloy Steel | 600-800 | 10-25 | Aerospace, Oil & Gas | 3.5 |

| Stainless Steel | 500-700 | 35-50 | Food Processing, Medical | 4.0 |

| Titanium Alloy | 900-1200 | 15-25 | Aerospace, High-Performance Applications | 7.0 |

| Aluminum Alloy | 300-500 | 10-20 | Construction, Transportation | 2.0 |

When considering the right hot forging part for your industrial needs, it’s essential to understand how hot forging compares to other forging methods, such as cold forging and warm forging. Hot forging involves shaping metal at high temperatures, which enhances its ductility and allows for complex shapes with reduced risk of cracking. In contrast, cold forging is performed at room temperature, leading to increased strength but limiting the complexity of the shapes produced. Warm forging sits between the two, allowing for some material flow without the full requirements of heat.

**Tips:** When deciding between these forging methods, consider the specific requirements of your project. If precision and tighter tolerances are critical, cold forging may be preferable. However, if you’re working with larger components or require intricate designs, hot forging should be your go-to method.

Another important aspect is the material compatibility. Certain materials perform better under specific forging conditions. For instance, metals like aluminum and titanium often benefit from hot forging due to their enhanced formability at elevated temperatures. Therefore, evaluating the material properties alongside your forging method will help ensure you select the most suitable process for your industrial application.

**Tips:** Always consult with material engineers to determine the best material choice for your forging needs, as this can greatly influence the performance and durability of the final product.

When selecting hot forging parts for industrial applications, accurately evaluating tolerances and specifications is critical. Precision in tolerances can significantly influence the performance and longevity of forged components. According to a recent report by the Forging Industry Association, adherence to specified tolerances can lead to cost reductions of up to 20% over the product lifecycle due to improved fit and reduced rework. The industry standard often emphasizes a tolerance range of ±0.5% to ±2% depending on part complexity and size, which should be carefully considered when making selections.

Tips: Always consult with your supplier to understand their capabilities regarding tolerances. Reviewing their manufacturing process can provide insights into whether they can meet your specific requirements. Additionally, consider the intended application of the part; for critical components, tighter tolerances may be necessary to ensure optimal functionality.

Specifications such as material grade, heat treatment processes, and surface finish are equally important. The American Society for Testing and Materials (ASTM) standards provide guidelines that can be referenced to ensure quality and performance. In the quest for the right hot forging part, it's essential to compare specifications against performance expectations to ensure that each component meets both the structural and performance criteria for your application.

When selecting hot forging parts for industrial applications, the importance of quality certification cannot be overstated. Certified components not only assure the integrity and reliability of the products but also signify adherence to stringent industry standards. According to a report from the American Society for Quality (ASQ), approximately 94% of organizations that implement quality management systems see improvements in their processes. This emphasizes that choosing certified hot forging components can substantially enhance operational efficiency.

Additionally, quality certification helps mitigate risks associated with product failure. The International Organization for Standardization (ISO) reports that companies with ISO 9001 certification experience up to 80% fewer product defects. This statistic illustrates that certified manufacturers are more likely to provide components that meet both safety and performance expectations, allowing businesses to maintain their production standards and reduce the likelihood of costly downtimes. Consequently, incorporating certified hot forging parts into manufacturing processes not only boosts product quality but also enhances overall trust in the supply chain, fostering long-term industrial relationships.