Leave Your Message

-

Phone

-

E-mail

When it comes to maintaining your vehicle, making the right choice for auto parts is crucial. Among the various materials available, stainless steel auto parts have emerged as a popular option for many car enthusiasts and everyday drivers alike. This durable and versatile material offers numerous benefits that enhance the longevity and performance of your vehicle. From improved corrosion resistance to the ability to withstand extreme conditions, choosing stainless steel auto parts can significantly impact the overall functionality of your car.

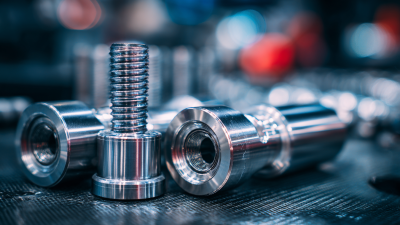

In addition to their robust nature, stainless steel auto parts are also known for their aesthetic appeal. Their shiny, sleek finish not only complements the design of your vehicle but also ensures that maintenance becomes easier, as these parts are less prone to rust and deterioration. Whether you're replacing a worn-out exhaust system, upgrading brake components, or investing in fasteners, stainless steel auto parts provide the reliability and performance that modern vehicles require.

Ultimately, opting for stainless steel auto parts reflects a commitment to quality and efficiency. As vehicle maintenance continues to evolve, understanding the advantages of these components becomes essential for both DIY mechanics and professional auto technicians. By prioritizing stainless steel options, you set the foundation for a smoother, more reliable driving experience while ensuring your vehicle remains in optimal condition for years to come.

Using stainless steel auto parts in vehicle maintenance offers numerous benefits that make them an ideal choice for car owners. One of the primary advantages is their exceptional resistance to corrosion and rust, which can significantly extend the lifespan of various components. Unlike conventional materials, stainless steel can withstand harsh environmental conditions, making it particularly suitable for vehicles exposed to moisture, road salts, and chemicals. This durability not only enhances the performance of auto parts but also reduces the need for frequent replacements, leading to long-term cost savings.

Additionally, stainless steel auto parts contribute to improved overall vehicle performance. The strength and lightweight nature of stainless steel can reduce the overall weight of the vehicle, which may enhance fuel efficiency and handling. Furthermore, stainless steel components can better maintain their structural integrity under extreme temperatures and stress, ensuring reliable operation even in demanding conditions. As a result, choosing stainless steel for vehicle maintenance can lead to a more reliable and efficient automotive experience, appealing to both everyday drivers and automotive enthusiasts alike.

| Benefit | Description | Durability | Corrosion Resistance |

|---|---|---|---|

| Longevity | Stainless steel parts outlast many other materials, reducing the need for frequent replacements. | High | Excellent |

| Maintenance | Easier to keep clean and requires less maintenance compared to other metals. | Moderate | Very Good |

| Aesthetics | Provides a sleek, modern appearance that enhances the look of any vehicle. | Good | Good |

| Performance | High heat resistance, enhancing the performance of various components. | High | Excellent |

| Eco-Friendly | Recyclable material, contributing to sustainability in automotive manufacturing. | Moderate | Good |

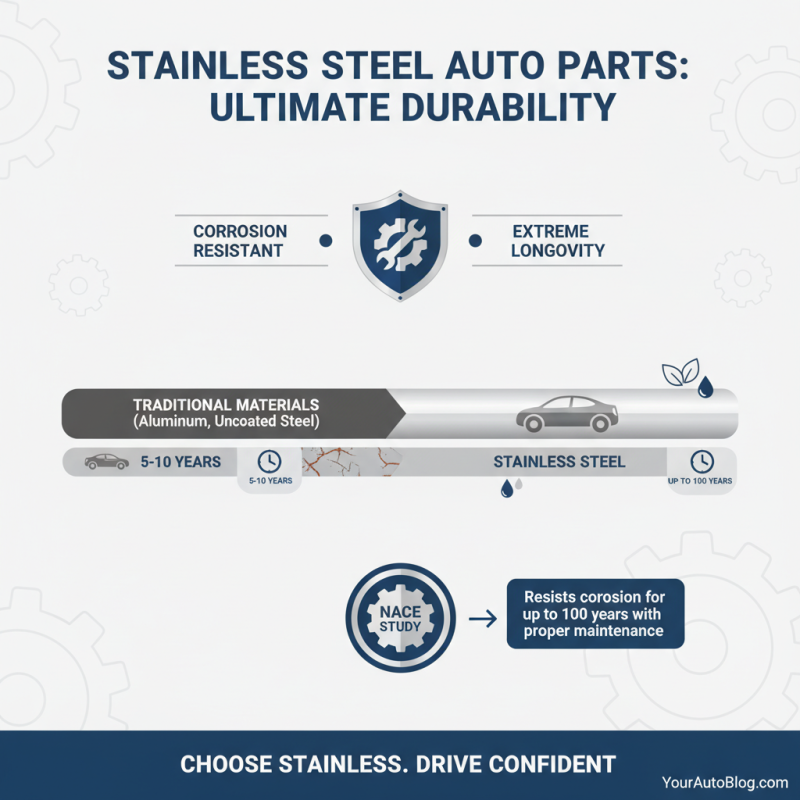

When it comes to automotive maintenance, opting for stainless steel auto parts is a decision driven by their remarkable durability and longevity. Stainless steel offers exceptional resistance to corrosion, a crucial feature in automotive applications where components are constantly exposed to moisture, road salt, and other harsh environmental factors. According to a study by the National Association of Corrosion Engineers (NACE), stainless steel can resist corrosion for up to 100 years when properly maintained, significantly outlasting traditional materials like aluminum or uncoated steel.

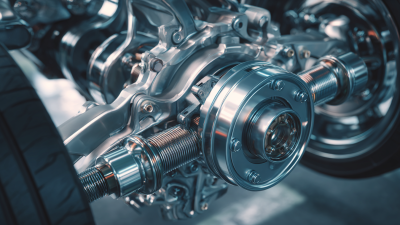

Additionally, stainless steel parts have high tensile strength, which allows them to withstand the stresses and strains of vehicle operation without breaking or deforming. Data from the American Iron and Steel Institute (AISI) reveals that stainless steel components can maintain their structural integrity under extreme conditions, including high temperatures and fluctuating pressures, making them ideal for critical automotive systems such as exhaust and brake systems. By incorporating stainless steel into vehicle maintenance routines, users not only enhance the lifespan of individual components but also ensure more reliable performance over time, ultimately resulting in cost savings on repairs and replacements.

When it comes to vehicle maintenance, the choice of materials for auto parts can significantly impact performance and longevity. One of the standout choices is stainless steel, particularly due to its exceptional corrosion resistance. Automotive components are regularly exposed to harsh environments, including moisture, road salt, and varying temperatures. These conditions can lead to rust and deterioration in traditional metal parts. However, stainless steel's unique alloy composition—including chromium—forms a protective layer that reacts with oxygen in the environment, effectively preventing rust and corrosion from taking hold.

The advantages of stainless steel extend beyond mere resistance to corrosion. Its durability and strength provide enhanced structural integrity, making it a reliable option for critical components. Unlike alternatives that may weaken over time or require frequent replacement, stainless steel parts can withstand the rigors of everyday use while maintaining their functionality and appearance. As a result, opting for stainless steel auto parts not only ensures a longer lifespan but also contributes to overall safety and vehicle reliability, making it a smart investment for any vehicle owner.

The cost-effectiveness of stainless steel auto parts has gained significant attention in recent years as vehicle maintenance practices evolve. According to a report by the International Stainless Steel Forum, stainless steel is known for its durability and resistance to corrosion, which can lead to reduced replacement and repair costs over time. While the initial investment in stainless steel components may be higher compared to traditional materials, the longevity and low maintenance requirements can result in significant savings. Studies indicate that stainless steel parts can last approximately 2.5 to 5 times longer than standard carbon steel parts, making them a financially sound choice for vehicle owners.

Moreover, maintenance costs can be reduced by as much as 30% when using stainless steel auto parts, as they often require less frequent servicing and are less prone to failure. A report from the Automotive Parts Manufacturers Association highlights that, despite higher upfront costs, the life-cycle costs of stainless steel components are lower due to their strong performance in harsh environments. The ability to withstand extreme temperatures and resist rust leads to fewer breakdowns, reducing the total cost of ownership for vehicle operators. As the automotive industry continues to prioritize sustainability and longevity, the shift towards stainless steel auto parts is not just a trend, but a strategic investment for vehicle maintenance.

Choosing stainless steel auto parts for vehicle maintenance not only enhances performance but also significantly reduces the environmental impact of automotive repairs. Stainless steel is renowned for its durability and resistance to corrosion, which leads to a longer lifespan for auto parts. This longevity minimizes the frequency of replacements, subsequently resulting in less waste entering landfills. By opting for stainless steel, consumers contribute to a more sustainable approach to vehicle maintenance by reducing the demand for new materials and the associated energy consumption required for production.

Moreover, the recycling potential of stainless steel further enhances its environmental advantage. Unlike many traditional automotive materials, stainless steel can be recycled multiple times without losing its essential properties. This closed-loop system fosters a circular economy within the auto parts industry, promoting resource conservation and reducing the carbon footprint associated with manufacturing. By selecting stainless steel parts, vehicle owners not only support eco-friendly practices but also partake in the movement towards sustainable automotive solutions that align with modern environmental consciousness.