Leave Your Message

-

Phone

-

E-mail

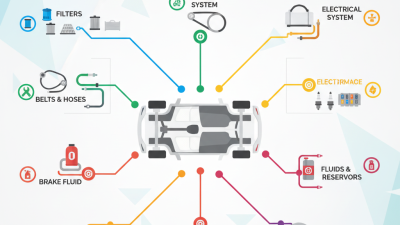

When it comes to engineering and manufacturing projects, selecting the right materials is crucial to ensure quality and durability. Among the various materials available, brass is renowned for its strength, corrosion resistance, and aesthetic appeal. Brass forging parts have gained popularity in diverse applications, from automotive components to decorative hardware, due to their ability to withstand stress while maintaining shape and functionality. However, choosing the appropriate brass forging parts for your specific project needs is not a straightforward task, as it demands a comprehensive understanding of material properties, manufacturing processes, and performance requirements.

In this guide, we aim to simplify the selection process for brass forging parts by addressing essential considerations that can influence your decision. Factors such as alloy composition, dimensional accuracy, surface finish, and the intended application will play a pivotal role in determining the ideal parts for your operation. By carefully analyzing these aspects, engineers and project managers can enhance the efficiency and effectiveness of their final products. Ultimately, making informed choices will not only improve the overall quality of the project but also contribute to long-term durability and reliability in the field.

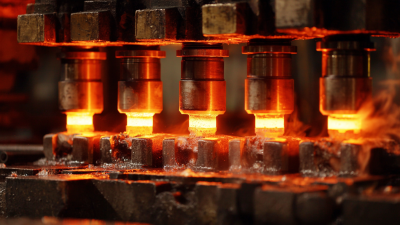

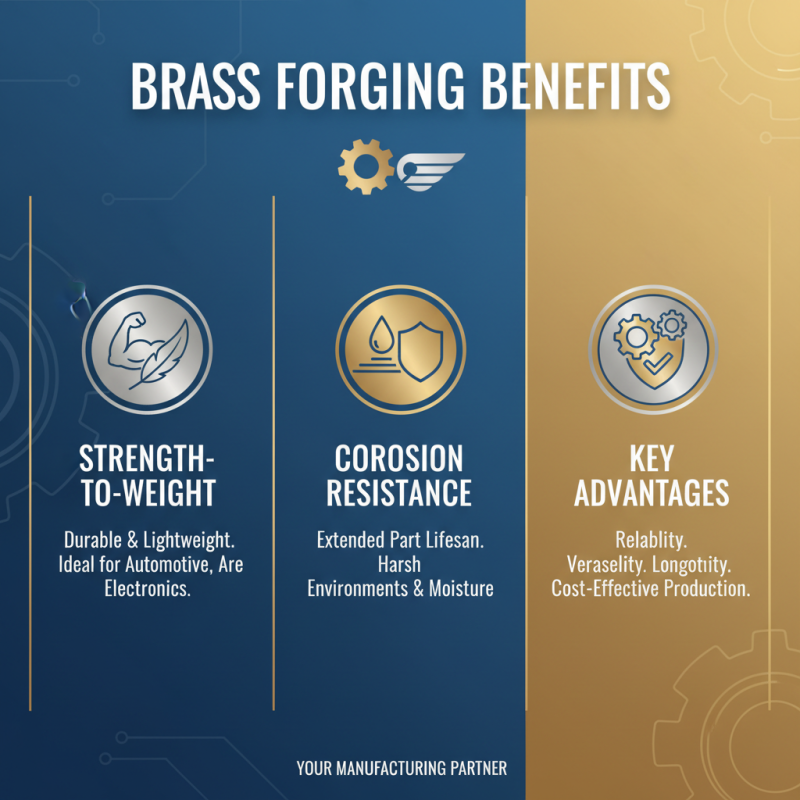

Brass forging is a manufacturing process that offers numerous advantages, making it a popular choice in various applications. One of the primary benefits of brass forging is its excellent strength-to-weight ratio. Forged brass parts are not only durable but also lightweight, making them ideal for use in sectors such as automotive, aerospace, and electronics. Additionally, brass exhibits excellent corrosion resistance, which extends the longevity of the parts made from it. This property is particularly valuable in applications that involve exposure to harsh environments or moisture.

When selecting brass forging parts, it’s crucial to consider the specific requirements of your project. The application will dictate the material's composition and the design specifications needed for optimal performance. Here are some tips to keep in mind: First, evaluate the environmental conditions the parts will face. This will help in choosing the right brass alloy. Secondly, consider the manufacturing tolerances required for your project; precision is key in ensuring the parts will fit and function as needed. Lastly, consult with your supplier about the best forging techniques available, as this can significantly influence the quality and performance of the final product.

When embarking on a project that requires brass forging parts, the first step is to clearly identify your project requirements. Understanding the specific characteristics you need—from dimensions and tolerances to mechanical properties—is crucial.

Consider factors such as the environment in which the parts will operate, the load they will bear, and any corrosion resistance they must offer.

These elements will guide your selection process and ensure that the final products meet the necessary standards for performance and durability.

Tips: Before making a decision, create a detailed list of your project specifications. This should include not only the physical dimensions, but also the intended use and any industry standards that need to be adhered to.

Engaging with engineers or design specialists can provide valuable insights into what types of brass alloys and forging processes might best suit your needs.

In addition to the technical specifications, consider the manufacturing capabilities of potential suppliers. Assess their experience with brass forging and their ability to scale production as your project grows.

Establishing a clear line of communication with suppliers can also help clarify any uncertainties and ensure that your requirements are met consistently throughout the production process.

Strong collaboration can lead to innovative solutions that enhance the performance of your brass forging components.

When selecting brass forging parts for your project, understanding the specifications tailored to your specific requirements is essential. The first step involves recognizing the mechanical properties required for your application, such as tensile strength, hardness, and ductility. These properties will determine how well the brass parts can withstand operational stresses and environmental conditions. Additionally, the choice of brass alloy is crucial, as different alloys exhibit varying characteristics, like corrosion resistance and thermal conductivity, which can significantly impact the performance of your project.

Another important aspect is the size and geometry of the forging parts. Accurate dimensions and tolerances must be defined to ensure proper fitment and functionality within your design. Considerations such as wall thickness, surface finish, and any specific features or features that need to be incorporated are critical. Furthermore, it’s vital to assess the manufacturing processes that will yield the desired results, ensuring that the chosen specifications align with the production capabilities and limitations, allowing for both efficiency and quality in the final products.

When evaluating manufacturers and suppliers of brass forging components, it is essential to consider several key factors that can impact the quality and suitability of the parts for your specific project needs. First, assess the manufacturer's experience and expertise in the brass forging industry. A company with a solid track record and technical know-how can offer valuable insights and better product quality. Look for certifications and compliance with industry standards, which can serve as indicators of reliable manufacturing practices.

Next, prioritize communication and customer service when selecting a supplier. A responsive and knowledgeable supplier can help you navigate the complexities of brass forging, ensuring that your requirements are met effectively. Additionally, consider their production capabilities and lead times. Suppliers that can demonstrate flexibility and a willingness to adapt to your project timeline are often more valuable partners. Finally, request samples or prototypes to gauge the craftsmanship of their products firsthand, which will help you make an informed decision based on tangible evidence of their capabilities.

| Feature | Description | Rating (1-5) | Lead Time (Days) | Min Order Quantity |

|---|---|---|---|---|

| Material Quality | High-grade brass alloy with excellent corrosion resistance. | 5 | 15 | 100 |

| Manufacturing Process | Advanced forging techniques ensuring precision and strength. | 4 | 20 | 50 |

| Customizability | Options for custom dimensions and specifications. | 5 | 30 | 20 |

| Pricing | Competitive pricing based on market standards. | 4 | 10 | 150 |

| After-sales Support | Reliable customer service and warranty options. | 5 | N/A | N/A |

Ensuring quality control in brass forging part production is paramount to the success of any project. The properties of brass, including its strength and corrosion resistance, make it a popular choice for numerous applications, but these advantages can only be realized if the forging process is meticulously controlled. From the selection of raw materials to the final inspection of the finished parts, each step plays a critical role in determining the overall quality of the products. Implementing standards and practices such as statistical process control can help monitor the production process, ensuring that any variations are detected and addressed promptly.

Additionally, thorough inspections should be an integral part of the production workflow. This includes not only visual checks for surface defects but also dimensional checks to ensure that components meet specified tolerances. Non-destructive testing methods, such as ultrasonic or magnetic particle inspection, can further enhance quality assurance by detecting internal flaws that may not be visible externally. By prioritizing these quality control measures, manufacturers can significantly reduce the chances of defects, ensuring that the brass forging parts produced are fully compliant with the desired specifications and capable of performing reliably in their intended applications.