Leave Your Message

-

Phone

-

E-mail

Cold forging die techniques are essential for maximizing efficiency and precision in the manufacturing process. As industries increasingly seek to enhance product quality while minimizing production costs, mastering these techniques becomes paramount. However, several problems often arise during the cold forging process, leading to suboptimal outcomes and increased waste.

Understanding the complexities of cold forging die design and implementation can mitigate these challenges. This blog will explore seven essential tips that address common issues associated with cold forging die techniques, providing insights into best practices that can improve both the quality of the final product and the overall efficiency of the production process.

By focusing on these critical aspects, manufacturers can achieve greater consistency and reliability in their cold forging operations, ultimately contributing to a more streamlined and cost-effective manufacturing environment.

Cold forging die techniques are essential for maximizing efficiency and precision in the manufacturing process. As industries increasingly seek to enhance product quality while minimizing production costs, mastering these techniques becomes paramount. However, several problems often arise during the cold forging process, leading to suboptimal outcomes and increased waste.

Understanding the complexities of cold forging die design and implementation can mitigate these challenges. This blog will explore seven essential tips that address common issues associated with cold forging die techniques, providing insights into best practices that can improve both the quality of the final product and the overall efficiency of the production process.

By focusing on these critical aspects, manufacturers can achieve greater consistency and reliability in their cold forging operations, ultimately contributing to a more streamlined and cost-effective manufacturing environment.

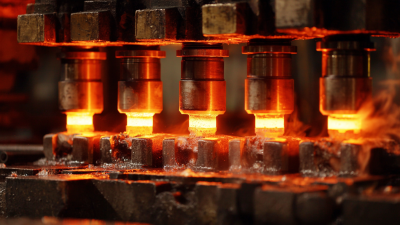

Cold forging is a crucial manufacturing process that shapes metals at room temperature, resulting in enhanced mechanical properties and surface finishes. This technique not only allows for the complex shaping of materials but also improves the strength of the final product. According to a report by MarketsandMarkets, the global cold forging market is projected to reach USD 28.8 billion by 2026, highlighting its increasing significance in various industries including automotive and aerospace.

Understanding the basics of cold forging is essential for mastering its die techniques. One key tip is to ensure the right temperature management; while the process occurs at room temperature, maintaining the ambient conditions can significantly affect the workpiece material properties. Another important aspect is the design of the die itself; incorporating proper draft angles and radii can lead to better material flow and reduced wear on the die. A study from the Journal of Materials Processing Technology found that optimizing die design can improve production efficiency by up to 25%.

As cold forging continues to evolve, mastering these techniques becomes increasingly important. Regularly updating your knowledge of materials and best practices can provide a competitive edge in this expanding market.

| Tip Number | Tip Description | Importance | Best Practices |

|---|---|---|---|

| 1 | Understand Material Properties | High | Research material compatibility and properties. |

| 2 | Optimize Die Design | Critical | Use CAD software for precise design modeling. |

| 3 | Control Temperature | High | Monitor temperature closely to prevent defects. |

| 4 | Choose the Right Lubrication | Important | Select lubricants suitable for cold forging. |

| 5 | Utilize Simulation Techniques | Highly Recommended | Run simulations to predict die performance. |

| 6 | Regular Maintenance Checks | Essential | Schedule routine inspections of die equipment. |

| 7 | Educate and Train Staff | Very Important | Offer training programs for staff on best practices. |

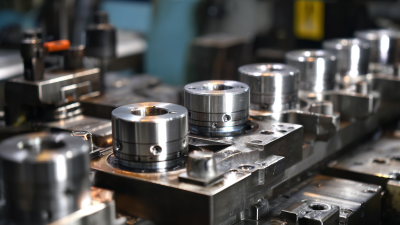

Cold forging is an advanced manufacturing process known for its efficiency and ability to produce

high-precision components. Mastering cold forging die techniques is essential for

manufacturers looking to enhance productivity and ensure the longevity of their tools. Key tools required

for these techniques include hydraulic presses, precision dies, and monitoring systems

that gauge loads during the forging process. Industry reports indicate that effective load monitoring can significantly reduce the

likelihood of static overload breakage in components like punches, which typically face increased

stress under high-pressure conditions.

Cold forging is an advanced manufacturing process known for its efficiency and ability to produce

high-precision components. Mastering cold forging die techniques is essential for

manufacturers looking to enhance productivity and ensure the longevity of their tools. Key tools required

for these techniques include hydraulic presses, precision dies, and monitoring systems

that gauge loads during the forging process. Industry reports indicate that effective load monitoring can significantly reduce the

likelihood of static overload breakage in components like punches, which typically face increased

stress under high-pressure conditions.

Advancements in technology have facilitated the development of smart cold forging die life cycle management systems. Such systems rely on real-time data acquisition to assess the performance and integrity of dies throughout their operational life. Research highlights that the implementation of in-process monitoring strategies can improve the predictability of tool failures, enabling proactive maintenance and reducing downtime. For instance, studies have shown that monitoring parameters such as force and temperature can lead to enhanced decision-making, thereby mitigating risks associated with fatigue failure in dies, which are traditionally designed through processes including shrink fitting to endure intense load conditions.

In today's competitive manufacturing landscape, optimizing die design is crucial for enhancing performance and durability in cold forging processes. Recent industry forecasts suggest that the die and mold market is projected to grow from $3.76 billion in 2025 to $5.47 billion by 2033, reflecting a compound annual growth rate (CAGR) of 4.79%. This growth highlights the increasing demand for innovative die designs that not only improve product quality but also ensure longevity and efficiency during production.

To achieve optimum die design, engineers must focus on advanced materials and techniques that reduce weight without compromising strength. The trend towards lightweighting in various industries, including robotics, illustrates the importance of material optimization. By employing innovative cooling structures and minimizing the modular form factor, manufacturers can enhance die performance while simultaneously decreasing overall weight. This approach not only extends the lifespan of dies but also facilitates more efficient operations, resonating with the industry's shift towards sustainable and high-performance solutions. As the demand for high-quality forged components grows, mastering these die techniques will be essential for staying competitive in the market.

Mastering cold forging techniques can significantly improve production efficiency and component precision, but there are common pitfalls that practitioners should navigate carefully. One prevalent mistake is improper material selection. Using the wrong material can not only lead to poor results but also compromise the integrity of the die. It's crucial to choose materials that are compatible with the intended forging process to ensure durability and performance.

Another frequent error arises from inadequate die design. A poorly designed die can create uneven pressure distribution, leading to defects in the forged part. Therefore, investing time in the initial design phase to analyze and simulate the forging process can save countless hours of rework later. Additionally, neglecting the importance of maintenance can lead to die wear, impacting the quality and consistency of the output. Regular inspections and timely repairs are essential for maintaining optimal die performance and achieving the best results in cold forging.

Mastering cold forging die techniques requires not only practical skills but also an understanding of advanced methods that enhance efficiency and precision. As industries increasingly demand lightweight components, particularly in aerospace, the cold forging market is experiencing significant growth, projected to reach USD 7.49 billion by 2032. This trend underscores the necessity for manufacturers to adopt innovative approaches and refine their die techniques to meet the stringent requirements of modern applications.

To improve efficiency, it's essential to utilize high-performance lubricants that facilitate smoother die operations and reduce wear. The cold forming lubricant market is also witnessing expansion, with expectations to increase from USD 1.2 billion in 2024 to USD 1.8 billion by 2033. Implementing the right lubricants not only optimizes production rates but also enhances precision in the forging process, ultimately resulting in better product quality.

Additionally, integrating techniques from advanced material science, such as high-entropy alloys, can further revolutionize the design and functionality of forged components, making it crucial for professionals to stay updated on the latest advancements in the field.