Leave Your Message

-

Phone

-

E-mail

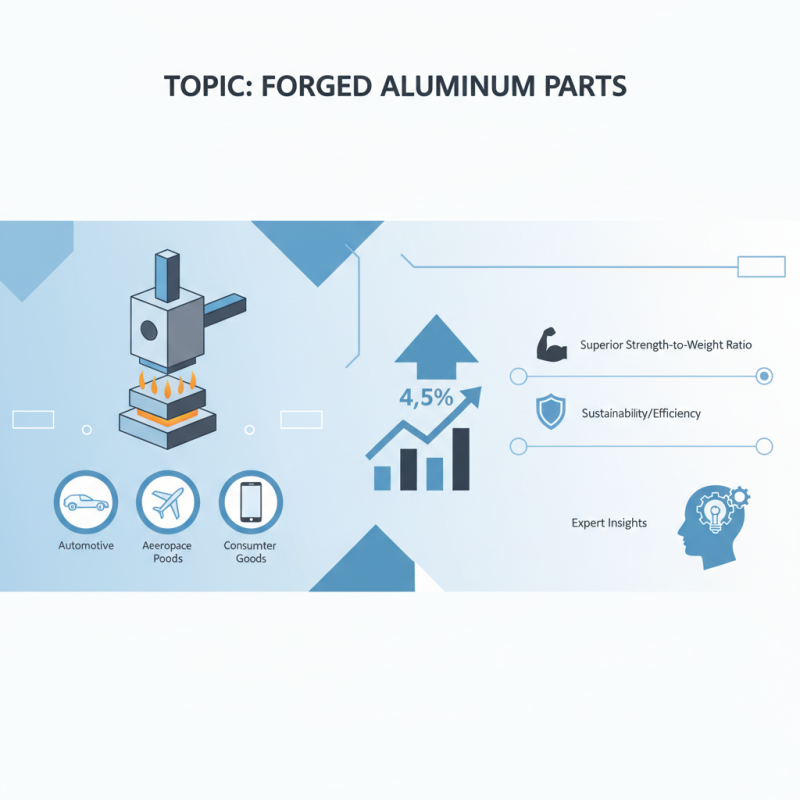

Forged aluminum parts have become increasingly prominent in various industries due to their superior strength-to-weight ratio and enhanced durability. According to a recent report by the Aluminum Association, the demand for forged aluminum products is projected to grow at a CAGR of 4.5% through 2025, driven by a surge in applications across automotive, aerospace, and consumer goods sectors. This growth reflects a broader trend towards lightweight materials that do not compromise on performance, making forged aluminum an ideal choice for manufacturers looking to improve efficiency and sustainability.

Expert Dr. John Smith, a leading authority in materials engineering, emphasizes the significance of these parts in modern manufacturing, stating, "Forged aluminum parts are revolutionizing the industry by providing a trusted solution for high-stress applications while reducing overall weight." His insights highlight the versatility and reliability of forged aluminum, which not only meets stringent industry standards but also supports innovation in design and production. As companies continue to prioritize advanced materials, understanding the benefits, applications, and manufacturing processes of forged aluminum parts will be essential for stakeholders aiming to stay competitive in the evolving market landscape.

Forged aluminum parts are essential components in various industries, known for their strength and lightweight properties. The forging process involves shaping aluminum alloy under high pressure, resulting in improved density and mechanical properties compared to cast metals. As the aluminum is shaped, its grain structure is refined, enhancing durability and resistance to fatigue, which makes it a preferred choice for applications requiring high performance under stress.

The benefits of forged aluminum parts include their exceptional strength-to-weight ratio, which allows for the design of lighter structures without compromising on strength. This attribute is particularly important in the aerospace and automotive industries, where every ounce counts. Additionally, forged aluminum can withstand harsh environmental conditions, making it suitable for use in outdoor applications and in components exposed to corrosion. The manufacturing process is also efficient, often resulting in lower production costs over time due to the reduction in material waste and the ability to create complex shapes with high precision. Overall, forged aluminum parts represent a vital technological advancement in materials engineering, providing unmatched performance and versatility across various sectors.

Forged aluminum parts have gained prominence in various industries due to their unique characteristics and the benefits they offer. One of the key advantages of using forged aluminum in manufacturing is its exceptional strength-to-weight ratio. This property makes forged aluminum an ideal choice for applications where reducing weight while maintaining strength is crucial, such as in aerospace and automotive sectors. Additionally, the forging process enhances the material's grain structure, resulting in superior mechanical properties and improved fatigue resistance.

Another significant benefit of forged aluminum is its excellent corrosion resistance. Unlike many other materials, forged aluminum can withstand harsh environments without significant degradation. This quality is particularly advantageous for components used in marine and outdoor applications. Furthermore, forged parts often exhibit better formability, allowing manufacturers to create complex shapes that meet stringent design specifications.

Tips for manufacturers considering forged aluminum parts include assessing the specific performance requirements and the environmental conditions the parts will face. Properly understanding the application’s needs will guide the selection of aluminum alloys and forging methods. Additionally, collaborating with experienced forging specialists can ensure that the best practices are employed in the manufacturing process, leading to enhanced part durability and performance.

Forged aluminum parts are widely utilized across various industries due to their superior strength-to-weight ratio and excellent durability. In the aerospace sector, these components play a critical role in reducing overall weight while maintaining structural integrity, which is essential for fuel efficiency and operational performance. Forged aluminum is commonly found in aircraft frames, engine components, and landing gear, where reliability and lightweight characteristics are paramount.

In the automotive industry, forged aluminum parts are used in various applications such as engine blocks, suspension systems, and wheels. The lightweight nature of forged aluminum contributes to improved fuel efficiency and better handling of vehicles. Additionally, industries like construction and consumer goods have begun to adopt forged aluminum due to its ability to withstand harsh conditions while being less cumbersome than traditional materials. These applications highlight the versatility and critical importance of forged aluminum parts across multiple sectors.

The manufacturing process of forged aluminum involves several key steps that ensure the production of parts with superior strength and durability. Initially, the process begins with selecting high-quality aluminum billets, which are then heated to a specific temperature. This heating enhances the material's malleability, making it easier to shape under pressure. Once heated, the billets are subjected to a forging operation, which can be done using various methods such as open-die or closed-die forging. This step specifically involves compressing the aluminum into the desired shape, significantly improving its mechanical properties through the alignment of the grain structure.

Following the forging process, the newly formed aluminum parts undergo cooling and subsequent heat treatment to further enhance their strength and ductility. This stage might include processes like quenching and aging, which stabilize the characteristics of the forged aluminum. After being treated, the parts are typically machined or processed further to achieve precise dimensions and surface finishes. Quality control checks are conducted throughout the manufacturing process to ensure that the final products meet stringent industry standards, making forged aluminum parts suitable for various applications, including automotive, aerospace, and construction industries.

When comparing forged aluminum to other metal forming techniques, several key differences emerge that highlight the advantages and applications of forging. Traditional methods such as casting and machining may offer simplicity, but they often fall short in terms of material integrity and strength. Forged aluminum parts are known for their superior mechanical properties due to the alignment of grains during the forging process, which results in increased fatigue resistance and durability. Unlike casting, which can trap impurities and form voids within the metal, forging compresses the material, enhancing its density and robustness.

Another notable advantage of forged aluminum over techniques like extrusion or stamping lies in its ability to produce complex geometries while maintaining dimensional accuracy. Forged components can sustain higher loads and perform better under extreme conditions, making them suitable for industries ranging from aerospace to automotive. While machining can provide precision, it generates waste material, ultimately increasing production costs. In contrast, forging minimizes waste and can often yield parts with near-net shapes, streamlining the manufacturing process and enhancing overall efficiency.

| Dimension | Forged Aluminum | Other Metal Forming Techniques |

|---|---|---|

| Strength | High tensile strength and impact resistance | Varies by technique, generally lower than forging |

| Weight | Lightweight due to aluminum's properties | Varies with the type of metal used |

| Cost | Higher initial costs due to forging process | Can be lower, depending on volume and complexity |

| Applications | Aerospace, automotive, electronics | Construction, machinery, consumer products |

| Manufacturing Process | Heat treatment, hammering, or squeezing | Casting, machining, stamping |