Leave Your Message

-

Phone

-

E-mail

Forged cylinders are vital components in various industries. They offer strength and reliability in demanding applications. These cylinders undergo a series of processes that enhance their durability compared to other manufacturing methods.

The creation of forged cylinders involves immense pressure and heat. This combination shapes raw materials into strong, precise forms. However, achieving consistent quality can be challenging. Each step, from heating to forging, must be monitored closely.

Forged cylinders may not be perfect. Some defects can arise during production. It is essential for manufacturers to reflect on these moments. Continuous improvement is necessary to ensure optimal performance. Despite the challenges, the benefits of forged cylinders make them a preferred choice in many sectors.

A forged cylinder is a specific type of mechanical component. It is created through a process called forging. This method involves applying high pressure to metal. As a result, the material becomes denser and stronger. Forged cylinders are widely used in automotive and aerospace industries. Their reliability under extreme conditions is notable.

One key characteristic of forged cylinders is their excellent structural integrity. They can withstand high levels of stress. Additionally, their resistance to fatigue makes them appealing for various applications. These cylinders can handle heavy loads without deforming. However, not every forged cylinder is perfect. Some may develop micro-cracks due to improper heating. This can compromise their strength.

Another important aspect is the material used. Commonly, steel alloys are preferred for their durability. However, the choice of alloy can influence performance. A wrong selection could lead to failures in critical applications. It is essential to test and analyze each forged cylinder thoroughly. Quality control is a must in production processes. Ignoring this step can result in issues later on.

This chart illustrates the estimated production time for each step in the forged cylinder manufacturing process. Each bar shows how many hours are typically spent on materials preparation, heating, forging, cooling, and finishing of the cylinder.

Forged cylinders are critical components in various industries. Their production relies heavily on specific materials. Common choices include steel and aluminum due to their strength and durability. Each material has its own unique properties, shaping the final product's performance.

Steel is often favored for its impressive tensile strength. It can withstand high pressures and extreme temperatures. Aluminum, on the other hand, is lighter and has excellent corrosion resistance. However, it may not provide the same level of strength as steel. Engineers must carefully choose between these materials based on the intended application.

The forging process involves heating the material to a malleable state, followed by shaping it under pressure. This method enhances the grain structure, leading to a stronger cylinder. However, imperfections can arise during production. Sometimes, inclusions or air pockets may be present. These flaws can affect performance. Regular inspection is essential to identify and rectify these issues before the cylinder is put to use.

The forging process for a cylinder involves several key steps. It begins with heating metal to a high temperature. This softens the material, making it malleable. Once heated, the metal is placed into a forge. Here, tools apply pressure, shaping it into a rough cylinder. This step uses a hammer or press. The force alters the grain structure, increasing strength.

After shaping, the cylinder is cooled. This cooling process can create imperfections. Sometimes, cracks occur due to rapid temperature changes. The next step involves machining to achieve precise dimensions. It’s crucial for fitting and functionality. Still, there is room for error. A miscalculation can lead to a poor fit in the final assembly.

Polishing and finishing follow machining. This enhances appearance and prevents corrosion. However, even the best processes have flaws. A finished product might reveal minute scratches or uneven surfaces. Each step in the forging process has its challenges. Understanding these can lead to improvements in future production.

Quality control is crucial in the production of forged cylinders. Each step must meet high standards. Any small error can lead to major issues. Forged cylinders are often used in heavy machinery. They must withstand high pressures and stresses. A defect could result in severe failures.

One common measure is visual inspection. Workers examine each cylinder for obvious flaws. They look for cracks or surface imperfections. However, this method has limitations. It may not catch hidden defects. Advanced techniques like ultrasonic testing are also employed. These methods can detect internal issues. Yet, they require skilled operators and can be costly.

Another critical aspect is material testing. The composition of the metal must match specifications. Variations can affect strength and durability. Some batches may not meet quality standards. In such cases, it's imperative to reevaluate the process. Regular audits and continuous training help improve outcomes.

Quality control is a never-ending journey, not a destination. Each cylinder tells a story of its creation, often revealing lessons learned along the way.

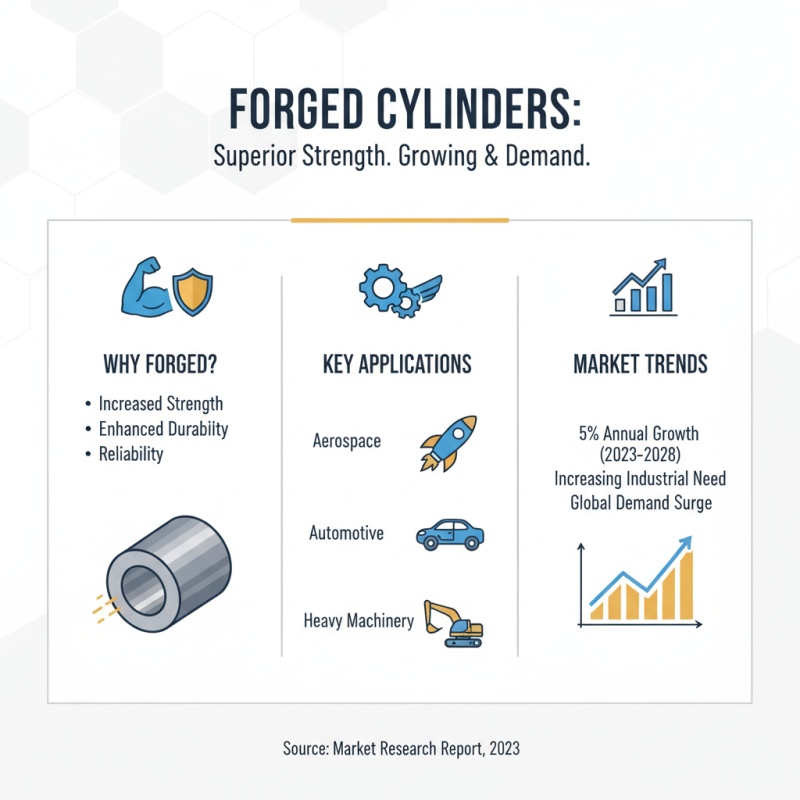

Forged cylinders are critical components in many industries. They offer superior strength and durability compared to other manufacturing methods. These qualities make them a preferred choice in applications such as aerospace, automotive, and heavy machinery. According to a recent market research report, the global demand for forged products is expected to grow by 5% annually over the next five years. This trend reflects the increasing need for reliable components in various sectors.

In the automotive industry, forged cylinders are widely used for engine components. Their ability to withstand high pressures and temperatures is essential for performance. A study from the Welding Journal reported that using forged components can enhance the lifespan of engine parts by up to 30%. Similarly, in oil and gas, these cylinders help in drilling and extraction processes. Their robustness is crucial for operations under extreme conditions. However, the forging process can sometimes lead to imperfections that may affect performance. Continuous improvement in manufacturing techniques is necessary to address these challenges.

Other industries like aerospace also benefit from forged cylinders. These components are vital in aircraft engines and landing gear, ensuring safety and efficiency. The global aerospace sector is projected to spend over $300 billion on advanced manufacturing technologies, including forging techniques. Yet, the complexity of these processes can lead to inconsistencies. Ongoing research and collaboration among industry professionals aim to mitigate these issues and enhance the reliability of forged products.