Leave Your Message

-

Phone

-

E-mail

In the contemporary landscape of manufacturing, the choice of materials plays a pivotal role in determining efficiency and durability. Among these materials, forged steel parts have emerged as a powerful component, known for their exceptional strength and resilience. The forging process enhances the grain structure of steel, resulting in components that possess superior mechanical properties compared to traditionally manufactured counterparts. As industries strive for greater reliability and performance, the impact of forged steel parts on modern manufacturing cannot be overstated. These robust components not only contribute to the longevity and functionality of machinery but also facilitate innovations that drive productivity. This exploration delves into the various types of forged steel parts, highlighting their remarkable advantages and the critical role they play in optimizing manufacturing processes for a range of applications.

Forged steel parts have become a cornerstone in modern manufacturing, offering unparalleled strength and durability compared to other materials. By definition, forging is a manufacturing process involving the shaping of metal using localized compressive forces. This method enhances the microstructure of the steel, resulting in improved mechanical properties. According to the Forging Industry Association, forged components can be up to 30% stronger than their cast counterparts, making them indispensable in industries such as automotive and aerospace.

The advantages of forged steel parts are numerous. Not only do they exhibit superior fatigue resistance and toughness, but they also demonstrate excellent dimensional consistency, essential for precision engineering applications. A study by Industry Research indicates that the global forged steel market is expected to reach USD 124.6 billion by 2026, growing at a CAGR of 4.72% from 2019. This growth reflects the industry's shift towards high-performance materials, highlighting the increasing reliance on forged steel parts to enhance overall manufacturing efficiency and product lifespan.

The manufacturing process of forged steel parts is a cornerstone of modern industrial efficiency. The techniques employed in forging, especially hot and cold forming, significantly enhance the mechanical properties of steel. For instance, research indicates that hot forging can increase the density of additively manufactured stainless steel preforms from 90% to over 99%, while also refining their microstructure by more than seven times. This results in homogeneous materials with fewer defects, which is crucial in applications ranging from automotive components to medical devices.

The manufacturing process of forged steel parts is a cornerstone of modern industrial efficiency. The techniques employed in forging, especially hot and cold forming, significantly enhance the mechanical properties of steel. For instance, research indicates that hot forging can increase the density of additively manufactured stainless steel preforms from 90% to over 99%, while also refining their microstructure by more than seven times. This results in homogeneous materials with fewer defects, which is crucial in applications ranging from automotive components to medical devices.

Innovations in forging also include advancements in specialty forgers' capabilities. These manufacturers can produce high-quality, seamless rolled rings and complex forged parts swiftly, demonstrating the increasing demand for precision and customization in the industry. A notable example is the recent $20 million expansion by a long-standing precision steel forging leader, aimed at modernizing production techniques. Such investments illustrate a broader trend in the manufacturing ecosystem, where companies are continually pushing the boundaries of technology and efficiency to meet the evolving requirements of diverse sectors, reinforcing the pivotal role of forged steel parts in the global market.

Forged steel parts have become a cornerstone in modern manufacturing, owing to their superior mechanical properties compared to other materials like cast iron or aluminum. According to a report by the Steel Forging Association, forged steel components exhibit a tensile strength of approximately 70,000 psi, significantly outperforming cast iron, which typically ranges around 25,000 psi. This enhanced strength-to-weight ratio allows manufactured products to withstand greater stress, making forged steel ideal in applications such as aerospace and automotive industries where performance and reliability are paramount.

Furthermore, the fatigue resistance of forged steel is another critical aspect that amplifies its manufacturing efficiency. A study published in the Journal of Materials Processing Technology indicates that forged steel can endure cyclic loads much longer than other materials, often exceeding those of cast or extruded alternatives by a factor of two or more. This longevity reduces maintenance costs and downtime in manufacturing processes. Additionally, the reduced waste generated during the forging process—compared to casting—further optimizes resource use, contributing to both economic and environmental sustainability in manufacturing practices.

| Material Type | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Toughness (J) | Cost per kg ($) | Machinability Score (1-10) |

|---|---|---|---|---|---|

| Forged Steel | 800 | 600 | 50 | 2.5 | 7 |

| Cast Iron | 400 | 250 | 30 | 1.8 | 5 |

| Aluminum Alloy | 400 | 250 | 20 | 3.5 | 8 |

| Stainless Steel | 600 | 450 | 40 | 4.0 | 6 |

| Carbon Steel | 500 | 350 | 35 | 2.0 | 7 |

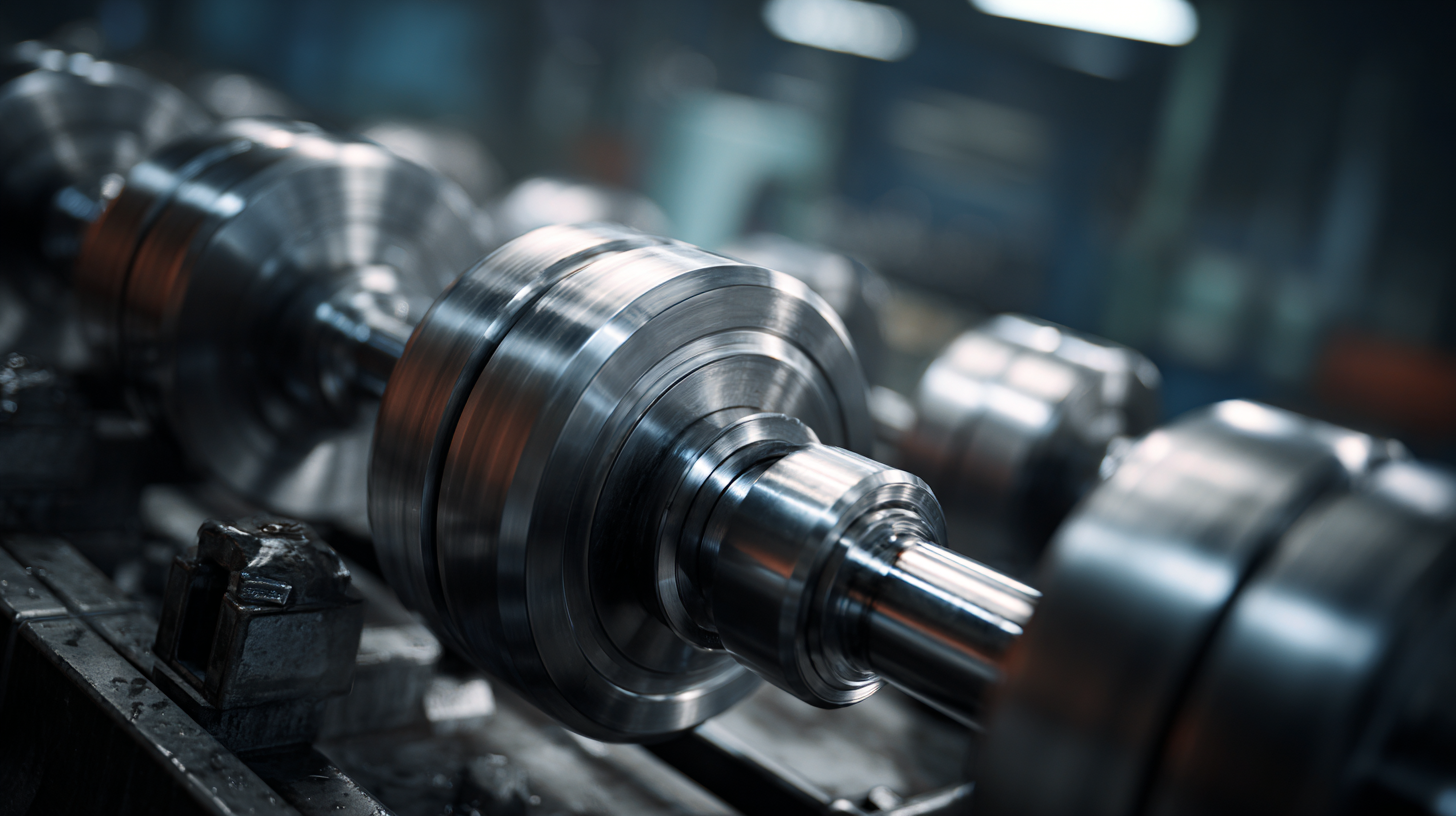

Forged steel parts are integral to various modern industries, renowned for their strength and durability. In the automotive sector, for instance, these components play a crucial role in manufacturing critical parts such as crankshafts, connecting rods, and gears. The forging process enhances the material's grain structure, resulting in superior mechanical properties that withstand immense stress and strain during operation. This transformation not only improves performance but also contributes to increased safety and longevity of vehicles.

In addition to automotive applications, forged steel parts are widely utilized in aerospace, construction, and energy sectors. For instance, in aerospace engineering, the high tensile strength of forged steel is essential for ensuring the reliability of components such as turbine blades and landing gear. Similarly, in the construction industry, forged steel is key in producing robust structural elements, including beams and connectors, that support buildings and bridges. The versatility and resilience of forged steel parts empower industries to meet demanding performance criteria, ultimately enhancing overall manufacturing efficiency.

Integrating forged steel components into production lines can significantly enhance manufacturing efficiency. First, assessing the specific needs of the operation is crucial. Identify which components can be replaced or enhanced by forged steel parts, focusing on their high strength-to-weight ratio and fatigue resistance. Such characteristics not only improve the durability of the machinery but also reduce maintenance costs and downtime, ensuring a smoother production flow.

Next, it is essential to train the workforce on the unique properties and handling requirements of forged steel materials. Familiarizing staff with the benefits and capabilities of these components promotes optimal use within production processes. Furthermore, collaborating with suppliers to establish a seamless supply chain can facilitate timely access to high-quality forged parts, reducing lead times and enhancing overall productivity. By strategically incorporating forged steel components, manufacturers can achieve a more efficient, robust, and reliable production system.