Leave Your Message

-

Phone

-

E-mail

Forged steel parts play a crucial role in various industries, from automotive to aerospace. According to a report by Allied Market Research, the global forged steel market is projected to reach $143.2 billion by 2028. This growth highlights the increasing demand for high-quality, durable materials in manufacturing.

These components offer significant advantages over cast or machined parts. Their superior strength-to-weight ratio makes them ideal for applications requiring high performance. For example, forged steel parts can withstand extreme conditions, reducing the risk of failure in critical applications. However, the forging process requires careful monitoring, and any flaws can lead to substantial losses in production.

Maintaining quality and precision in forged steel parts is essential. As the technology advances, it is crucial for manufacturers to address challenges in material consistency. This ongoing journey towards excellence in forging reflects a commitment to safety and reliability in every sector.

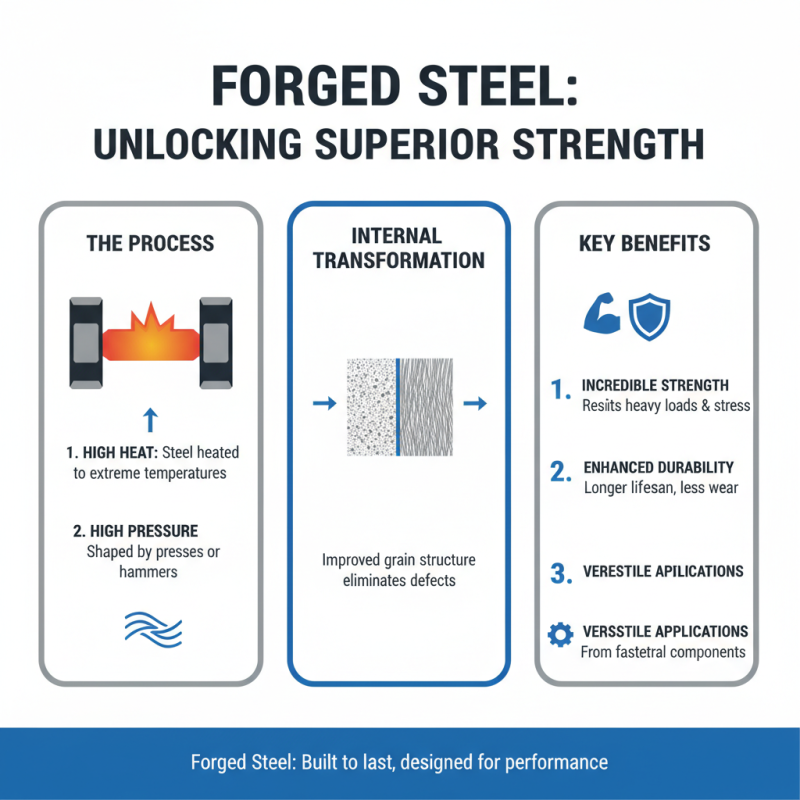

Forged steel parts are created through a process of shaping steel using high pressure and heat. This process enhances the internal structure of the metal. As a result, forged steel demonstrates remarkable strength and durability. The method can produce a wide range of components, from small fasteners to large industrial parts.

The manufacturing process begins with heating the steel to a high temperature, making it malleable. Once the steel reaches the right temperature, it is subjected to mechanical force. This force shapes the steel while also refining its grain structure. After forging, the parts may undergo additional processes like machining or heat treatment. These steps refine the dimensions and properties further.

While forged steel parts are known for their strength, the process is not without challenges. It requires precise control over temperatures and forces. Any errors can result in defects, impacting performance. The complexity of this process demands a skilled workforce and careful planning. The benefits, however, truly outweigh the drawbacks when the process is executed well.

Forged steel parts are essential in various industries due to their strength and durability. There are several common types of forged steel parts, each serving specific purposes. For instance, crankshafts are vital in automotive applications. They endure high stress and require exceptional resilience. In fact, the Automotive Engineering Society reports that properly forged crankshafts can improve engine performance by up to 15%.

Another significant category is gears, frequently used in machinery and appliances. Forged gears offer superior wear resistance, reducing replacement costs. Their precision engineering ensures reliable operation in high-load environments. A recent study by the Manufacturing Institute indicates that nearly 70% of industrial failures stem from gear malfunctions. Thus, using forged gears can mitigate these risks significantly.

However, it's important to acknowledge challenges. The forging process requires substantial energy input, raising cost concerns. Additionally, waste production is a critical issue. Finding ways to improve efficiency in forging remains an ongoing challenge for manufacturers. Despite these hurdles, the benefits of forged steel parts continue to drive innovation in various sectors.

Forged steel parts stand out for their unique properties. These parts undergo a manufacturing process that enhances their strength and durability. Unlike cast or machined options, forged steel exhibits superior structural integrity. This is crucial for components that face extreme stress.

The advantages of forged steel parts are significant. They tend to be denser than those made from other materials. This density translates to improved performance in demanding applications. Additionally, forged steel components can withstand high temperatures and pressures. They are less likely to crack or break when faced with harsh conditions. Forged steel also offers better fatigue resistance.

While the benefits are clear, it’s important not to overlook potential drawbacks. Forged steel can be more expensive due to the complex manufacturing process. Not every application requires these robust properties. There are instances where lighter materials might suffice. Balancing costs and benefits is essential for making informed decisions. Understanding the specific needs of a project can lead to better outcomes.

Forged steel parts play a crucial role in various industries. The automotive sector is a significant user. These parts enhance the strength of vehicle components, leading to improved safety and reliability. They withstand high stress and temperature. For instance, crankshafts and connecting rods are commonly forged. However, the challenge lies in adjusting the manufacturing processes to meet specific needs.

The aerospace industry benefits from forged steel parts as well. Components like landing gear and structural supports require high durability. Moreover, the weight-to-strength ratio is essential for performance. It’s complex, and sometimes it’s difficult to strike the right balance. Mistakes in forging can lead to flaws, affecting the entire assembly. Each piece must be carefully tested to ensure safety.

Manufacturers in the heavy machinery sector also rely on forged steel parts. These parts resist wear and tear, extending equipment lifespan. Yet, the challenge is to maintain quality across different batches. Variability can arise from raw materials or methods. Continuous improvement in processes is critical to minimize defects and improve reliability.

The production of forged steel parts is evolving rapidly. Industry reports indicate a projected growth rate of 5.4% in the forged steel market over the next five years. This growth stems from increasing demand in the automotive and aerospace sectors. Innovations in manufacturing processes are driving efficiency. Advanced techniques such as precision forging are gaining traction. These methods reduce waste and improve material properties.

However, challenges persist. The steel forging industry faces pressure to adopt sustainable practices. Rising energy costs and environmental regulations push manufacturers to rethink their processes. Many companies are exploring hybrid techniques. These blend traditional forging with modern technologies like additive manufacturing. Despite the potential, integration remains complex. Training and investment in new equipment pose significant hurdles.

The trend toward digitalization is also noteworthy. Smart manufacturing solutions are being implemented to enhance production. For instance, real-time data collection helps pinpoint inefficiencies. But, the transition can be slow and fraught with technical glitches. The need for skilled workers in this new era is critical. A focus on education and training is essential to prepare the workforce. As the demand for forged steel parts rises, the industry must adapt or risk falling behind.