Leave Your Message

-

Phone

-

E-mail

Forging machine parts play a vital role in various industries, shaping the components we rely on daily. According to industry expert John Smith, "The strength of a product often comes from the forge." This highlights the importance of forging in enhancing the durability and performance of machine parts.

These parts undergo a unique manufacturing process, involving the application of pressure to shape metal. Hot and cold forging methods create versatile and resilient pieces. However, the process is not without challenges. Ensuring precision while maintaining material integrity can be tricky.

As manufacturing technology evolves, some may overlook the flaws in current forging techniques. There is always room for improvement in efficiency and sustainability. Exploring advancements in forging machine parts can lead to innovative solutions. Understanding these intricacies is crucial for manufacturers aiming to optimize their production and embrace quality.

Forging machines play a crucial role in manufacturing various metal parts. These machines apply compressive forces to raw metal, shaping it into desired forms. The process begins with heating the metal to a malleable state. This stage is critical. If the metal isn’t heated properly, the results can be disastrous, leading to cracks or incomplete shapes.

In a typical forging process, large hammers or presses deliver force to the heated metal. The metal flow needs to be observed closely. An uneven strike can create weak spots in the final product. Operators must maintain a delicate balance between speed and pressure. Too much pressure can warp the part; too little can fail to shape it correctly.

Interestingly, the skill of the operator directly influences the quality of the forged parts. Not all operators use the same techniques. Some experiment with different striking patterns, hoping for innovation. This trial-and-error approach can lead to inconsistencies. Manufacturers must reflect on these variations to improve their processes. Ultimately, the goal is to create durable parts that meet exact specifications. It's a complicated yet fascinating aspect of modern manufacturing.

Forging is a crucial method for producing machine parts. It transforms metal into desired shapes through compressive forces. There are several types of forging processes, each suited for different applications. The primary types include open-die forging, closed-die forging, and hot forging.

Open-die forging allows flexibility in shape. Large metal pieces, such as shafts, can be easily manipulated. However, achieving precise dimensions may be challenging. In contrast, closed-die forging uses a mold to create specific shapes. This process results in better accuracy but can be limited by mold design and material.

Hot forging heats metal to improve ductility, reducing the risk of cracking. This method enables the forging of complex shapes. On the downside, it requires careful temperature control. For effective forging, it’s essential to select the right process. Tips: Make sure to consider material properties. Analyze how well each process aligns with your project needs. Reflect on any potential trade-offs to ensure optimal results.

Forging machine parts rely on specific materials that enhance their durability and performance. Steel is the most common choice. Its strength and flexibility make it ideal for various applications. Carbon steel, for example, provides excellent tensile strength as well as fatigue resistance. Furthermore, alloy steel introduces a combination of elements to improve hardenability. This results in stronger, more resilient parts.

Other materials include aluminum and titanium. Aluminum is lightweight yet strong. Its resistance to corrosion makes it popular in industries like aerospace. Titanium, on the other hand, is incredibly strong and lightweight. It performs well in high-temperature environments. However, it can be expensive and challenging to work with, which poses some limitations for manufacturers.

An often overlooked material is brass. It’s not as strong as steel but offers excellent corrosion resistance. This makes it suitable for specialized applications. Each material has its pros and cons. The challenge lies in choosing the right one for the specific needs. Balancing cost, performance, and manufacturability is key. Mistakes in material selection can lead to failure in the final product, requiring careful consideration.

| Material Type | Properties | Common Applications | Advantages |

|---|---|---|---|

| Steel | High tensile strength, ductility, and hardness | Automotive parts, aerospace components | Durability, cost-effectiveness |

| Aluminum | Lightweight, corrosion-resistant, good thermal conductivity | Aircraft structures, automotive engine parts | Lightweight, easy to machine |

| Titanium | High strength-to-weight ratio, excellent corrosion resistance | Marine applications, medical implants | Biocompatibility, high strength |

| Brass | Good machinability, corrosion resistance | Plumbing fittings, electrical components | Aesthetic appeal, excellent corrosion resistance |

| Carbon Steel | Fair tensile strength, good wear resistance | Tooling, construction equipment | Versatility, affordability |

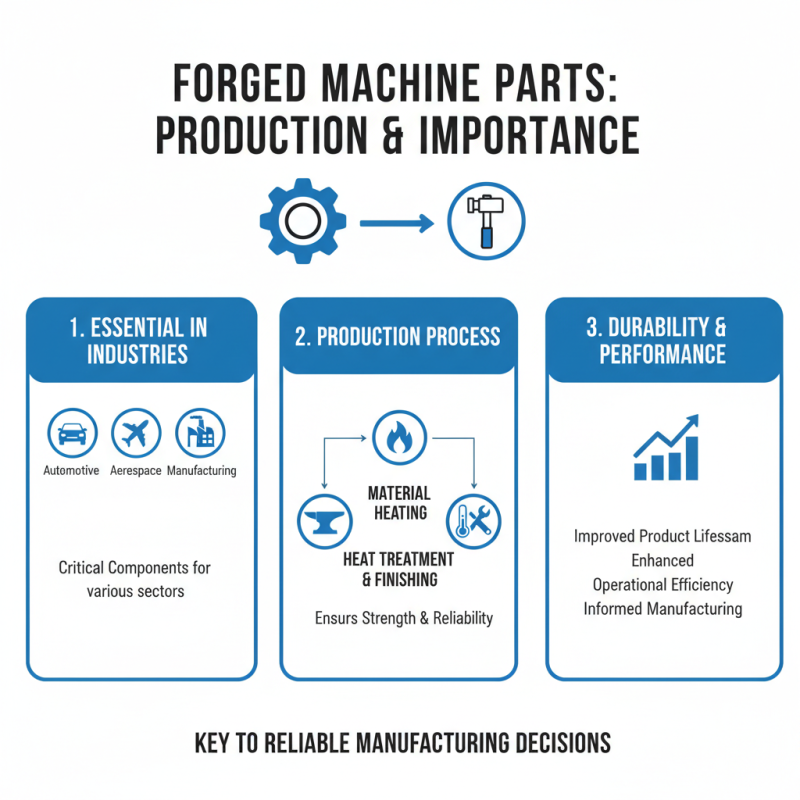

Forged machine parts are essential in various industries. The production process is vital to ensure product durability and performance. Understanding this process can lead to better manufacturing decisions.

The first step in forging is material selection. Metallurgists often prefer carbon steel or alloy steel due to their excellent mechanical properties. Next, the material is heated to its recrystallization temperature. This is usually between 1,100 and 1,200 degrees Celsius. At this point, the metal becomes pliable, allowing it to be shaped efficiently.

Once heated, the metal is transferred to a forging die. The die impacts the workpiece under high pressure. This pressure can reach up to 2,000 tons depending on the part’s design. After shaping, the forged parts undergo cooling. The cooling rate significantly influences the final properties. Improper cooling can lead to internal stresses.

Tips: Monitor temperature precisely. A small deviation can ruin the forging process. Always ensure tools are maintained. This can prevent delays and quality issues.

In terms of quality control, non-destructive testing is often employed. This ensures that any flaws are detected early. Studies show that 80% of forging-related defects stem from improper processing techniques. Thus, a comprehensive review of production methods is crucial.

Tips: Regularly update training for workers. Knowledge gaps can lead to increased error rates. Assess the production line frequently to identify areas of improvement.

In the production of forging machine parts, quality control measures are crucial. According to a 2022 report by the International Organization for Standardization (ISO), up to 30% of manufacturing defects arise from poor quality control. Effective control measures can significantly reduce this percentage.

Inspection processes begin as soon as raw materials arrive. Metallurgical tests check the composition and structure of alloys, ensuring they meet specifications. Visual inspections follow during each forging stage. These checks help identify surface defects early. Automated systems also play a role. They can detect inconsistencies with precision.

Despite advancements, challenges persist. Some manufacturers report a gap between quality expectations and actual outcomes. A recent survey indicated that 25% of forging operations struggle with consistent quality due to outdated equipment. Continuous training for staff is vital. Skilled workers bring a keen eye for details. They can spot issues a machine might miss. Quality in forging is not just a process; it’s a culture of constant improvement.