Leave Your Message

-

Phone

-

E-mail

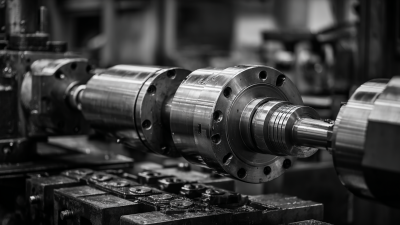

In today's industrial landscape, efficiency is crucial for maintaining competitiveness and meeting consumer demands. As businesses strive to optimize their production processes, the role of Forging Machine Parts cannot be overstated. According to John Smith, an expert in industrial engineering and the author of several key publications on manufacturing technologies, "The integration of advanced forging machine parts not only enhances operational efficiency but also significantly reduces the production costs." This insight highlights the importance of investing in high-quality forging solutions that align with modern manufacturing needs.

The evolution of Forging Machine Parts has been pivotal in driving innovations across various industries, including automotive, aerospace, and construction. By utilizing these robust components, manufacturers can achieve improved strength and durability in their products while minimizing waste. As Smith emphasizes, “Leveraging advanced forging technologies is essential for companies looking to scale their operations and enhance product reliability.” Such advancements are not merely incremental; they represent a transformative shift that can redefine industry standards.

As we delve deeper into the data insights surrounding Forging Machine Parts, it becomes clear that their role extends beyond mere functionality. They are integral to fostering a culture of efficiency and sustainability in manufacturing, paving the way for a more resilient industrial future. Understanding these dynamics is essential for stakeholders aiming to capitalize on the potential of forged components in the rapidly evolving market.

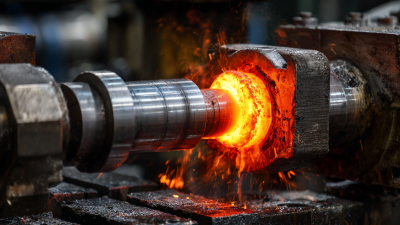

In the ever-evolving landscape of industrial manufacturing, forging plays a pivotal role in enhancing production efficiency. According to the 2022 Forging Industry Association report, forged parts are renowned for their strength and durability, achieving up to 30% better performance in terms of mechanical properties compared to their cast counterparts. This advantage is particularly crucial in sectors such as automotive and aerospace, where the integrity of components directly impacts safety and performance.

Moreover, the integration of advanced forging technologies, like automated die forging, has been shown to significantly reduce cycle times. A study from the International Journal of Advanced Manufacturing Technology highlights that implementing automation in forging processes can lead to efficiency improvements of up to 50%. This not only streamlines production but also enables manufacturers to respond more swiftly to market demands, ultimately driving growth and innovation. The data underscores the vital contribution of forging machines in optimizing industrial production and maintaining a competitive edge in the market.

Forging machine parts play a critical role in enhancing industrial efficiency, and understanding their impact requires a careful examination of key metrics. One primary metric is the yield strength of forged components, which often exceeds that of cast or machined parts. This improved strength contributes to longevity and reduces the frequency of replacements, thereby lowering operational costs. Additionally, reducing material waste during production through forging techniques supports sustainability efforts, making operations not only more efficient but also environmentally friendly.

Another important measure is the cycle time associated with production processes. Forging can significantly decrease cycle times compared to traditional machining methods, allowing manufacturers to increase throughput without compromising quality. The rapid production capability fosters a more agile manufacturing environment, enabling companies to respond quickly to market demands. Ultimately, these performance indicators highlight how forging machine parts contribute to operational excellence and competitive advantage in the industrial sector.

The manufacturing landscape has evolved with various processes to enhance efficiency and reduce costs, but forging remains a prominent choice, especially in industries like automotive. Forging processes are known for producing strong and durable machine parts due to the malleability of metals under pressure. This intrinsic quality makes forged components integral to automotive applications where reliability is critical. Compared to processes like casting, which often results in voids and weaknesses, forging ensures uniformity and structural integrity, leading to longer-lasting parts.

In the comparative analysis of forging with other methods such as machining and additive manufacturing, the advantages of forging become more evident. While machining can offer high precision, it often requires multiple steps and generates more waste material. Additive manufacturing provides design freedom but may not achieve the same material strength as forged parts. The automotive balance shaft market, projected to grow significantly, highlights the increasing demand for forged components that contribute to overall industrial efficiency. As manufacturers seek to optimize production processes, forging stands out as a reliable option that meets the demands of advanced automotive engineering.

The advancement of forging machinery has significantly influenced industrial efficiency, driven by innovations that enhance precision and productivity. Recent industry reports indicate that automated forging technology can boost production rates by up to 30%, allowing manufacturers to meet rising demand without compromising quality. These technological advancements encompass computer numerical control (CNC) systems, real-time monitoring, and advanced materials, which collectively contribute to a more streamlined forging process.

In addition to improving output, modern forging machinery also plays a vital role in the sustainability of industrial operations. Research from the Forging Industry Association reveals that energy-efficient forging processes can reduce power consumption by 20-40% compared to traditional methods. This not only lowers operational costs but also aligns with global sustainability efforts by minimizing the carbon footprint of manufacturing activities. As industries increasingly prioritize efficiency and environmental consciousness, investing in cutting-edge forging machinery is becoming indispensable for remaining competitive in the marketplace.

Forged machine parts have emerged as crucial components in various industrial applications, contributing to enhanced durability and performance. For instance, a leading automotive manufacturer implemented forged steel components in their engine production, resulting in a significant reduction in weight while improving overall strength. This transition not only optimized fuel efficiency but also extended the lifespan of the vehicles, showcasing the effectiveness of forged parts in real-world scenarios.

Another compelling case study comes from the aerospace sector, where a major airline incorporated forged titanium components into their aircraft designs. The results were dramatic: a decrease in maintenance costs and improved safety standards. By leveraging the superior mechanical properties of forged materials, this airline could ensure better performance under high-stress conditions, demonstrating that investing in forged parts can lead to long-term operational advantages.

**Tips for Implementation:** When considering the integration of forged parts into your production line, evaluate the specific performance needs of your machinery. Collaborating with suppliers who specialize in forging technology can provide insights into the best materials and designs for your applications. Additionally, conducting a cost-benefit analysis to understand potential savings in maintenance and efficiency will strengthen your decision-making process.

| Industry | Forging Process Used | Time Saved (% Reduction) | Material Waste (% Reduction) | Cost Savings (% Reduction) |

|---|---|---|---|---|

| Automotive | Closed Die Forging | 20% | 15% | 25% |

| Aerospace | Open Die Forging | 30% | 10% | 20% |

| Heavy Machinery | Hammer Forging | 25% | 5% | 15% |

| Energy | Precision Forging | 35% | 20% | 30% |

| Electronics | Roll Forging | 15% | 25% | 10% |