Leave Your Message

-

Phone

-

E-mail

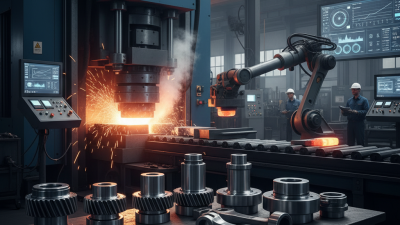

In the world of metalworking, forging machines play a pivotal role in shaping materials to achieve desired specifications and optimal performance. To ensure the efficiency and longevity of these machines, understanding the essential components that make up forging machine parts is crucial. The right selection and maintenance of these parts can significantly impact the overall productivity and quality of the forged products.

This article explores the top 10 forging machine parts that every operator and technician should be familiar with. From the primary components that facilitate the actual forging process to those that support the machine's functionality and reliability, each part plays a vital role in achieving excellence in production. Gaining insights into these components not only aids in informed purchasing and maintenance decisions but also empowers users to optimize the performance of their forging machines, ultimately enhancing their operational success in a competitive market.

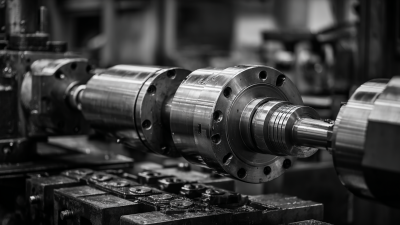

When it comes to the optimal performance of forging machines, understanding the essential parts is crucial. The heart of any forging operation lies in its components, which determine not only efficiency but also the quality of the final product. Key parts such as dies, which shape the material during forging, and hammers, which provide the necessary mechanical force, are fundamental to the process. Maintaining these components ensures that they operate smoothly and contribute to consistent results.

Another vital aspect of forging machines includes the hydraulic systems that provide the necessary pressure for forging operations. These systems must be regularly inspected and serviced to prevent failures that could lead to downtime. Similarly, the control systems, which manage the machine's operation and ensure precision, are indispensable for modern forging operations. Investing in the right spare parts and proactively maintaining them can significantly enhance productivity and extend the lifespan of the forging machine. Understanding these essential components is key to achieving optimal performance in any forging endeavor.

This bar chart represents the importance of various forging machine parts in achieving optimal performance. Each part is ranked based on its impact on efficiency and productivity in forging operations.

In the world of forging, anvils play a pivotal role in shaping and molding metal. Anvils provide a solid surface upon which raw materials are hammered and manipulated, allowing for precise control over the forging process. Their robust construction and design are essential for enduring the repeated impact of hammers and other forging tools, ensuring that they maintain their integrity and effectiveness over time. The effectiveness of an anvil is often determined by its weight, shape, and the quality of its surface, which must be hard enough to absorb and distribute the force exerted during forging.

Moreover, the type of anvil used can significantly influence the outcome of the forged product. Different anvils are designed for various forging techniques, such as blacksmithing or industrial forging. For instance, a flat anvil might be suitable for general-use applications, while more specialized anvils may include features such as horns or rounded surfaces to facilitate specific shapes and contours in the metal. Understanding the nuances of anvils is crucial for any forging operation aiming for optimal performance, as the right anvil can enhance efficiency, precision, and the overall quality of the final product.

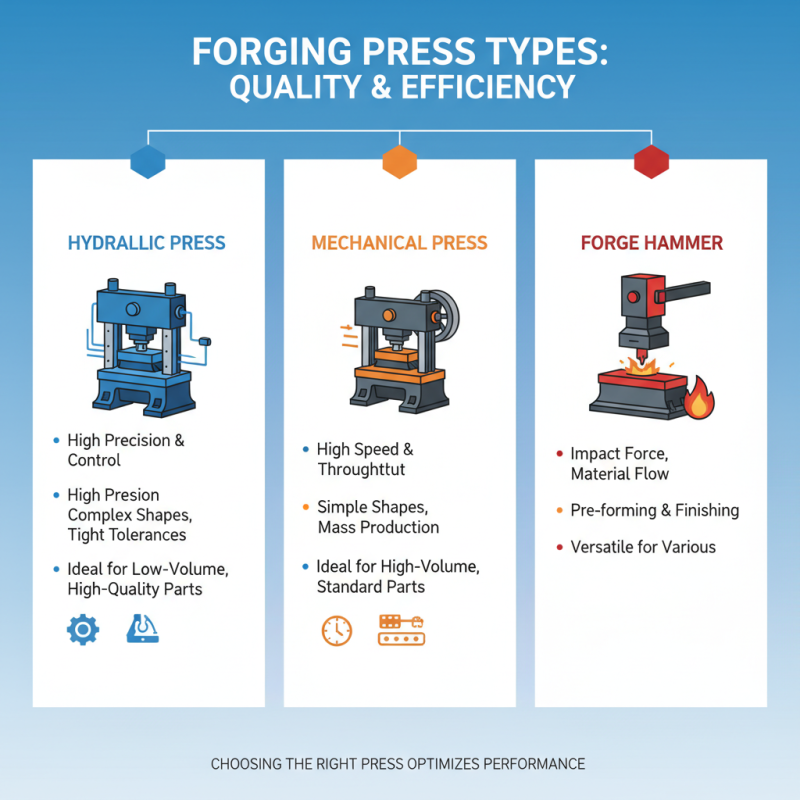

The choice of forging press type significantly influences both product quality and production efficiency. Different types of forging presses, such as mechanical, hydraulic, and forge hammers, each have unique operational characteristics that affect the forging process. For instance, hydraulic presses offer high precision and control, making them ideal for producing complex shapes with tight tolerances. On the other hand, mechanical presses often provide higher speeds, which can enhance productivity in high-volume production environments. Understanding these differences is critical for manufacturers aiming for optimal performance in their operations.

Tips for achieving the best results with your chosen forging press include regularly maintaining machinery to prevent wear and tear, thus ensuring consistent performance. Additionally, calibrating the equipment to suit the specific requirements of each forging job can further enhance both quality and efficiency. Finally, training operators on the nuances of each press type can reduce errors and improve overall output, as a knowledgeable workforce can make better decisions on how to adjust parameters for varying materials and designs.

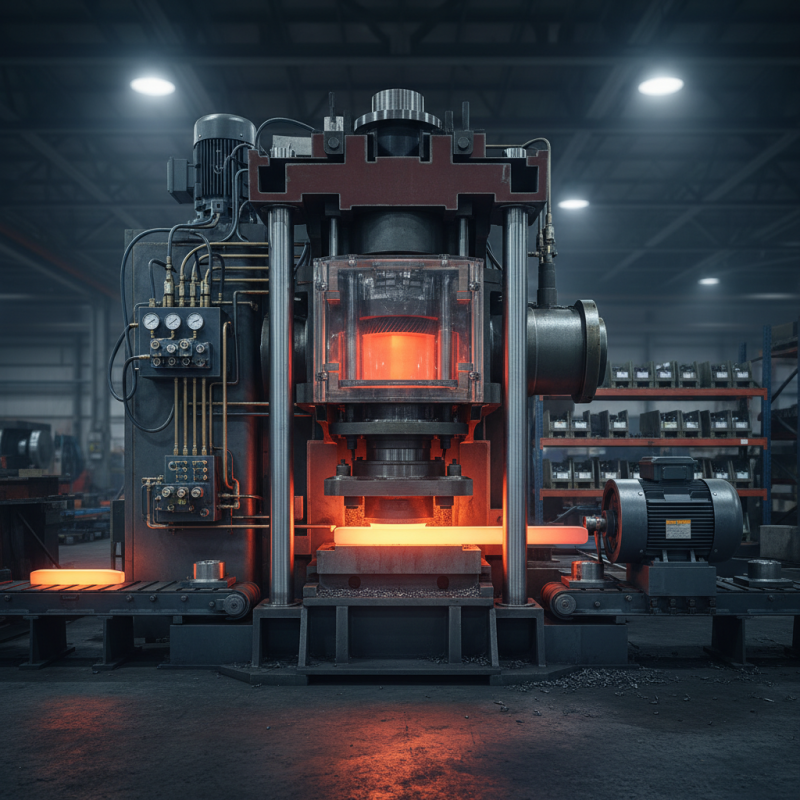

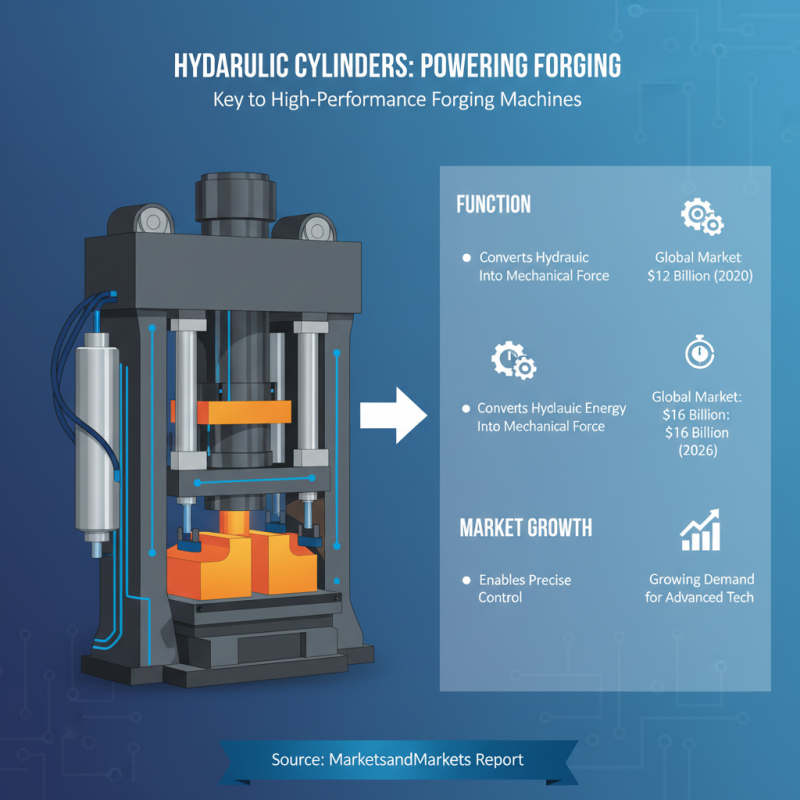

Hydraulic cylinders play a crucial role in the performance of high-performance forging machines, offering the necessary force to drive the forging process effectively. These cylinders convert hydraulic energy into mechanical energy, enabling precise control over the forging operation. According to a report by MarketsandMarkets, the global hydraulic cylinder market was valued at approximately $12 billion in 2020 and is projected to reach $16 billion by 2026, indicating a growing demand for advanced hydraulic technologies in manufacturing processes.

One of the key features of hydraulic cylinders in forging machines is their ability to provide high force output while maintaining compact sizes. This is vital for applications that require significant pressure levels, often exceeding 3,000 psi in forging operations. The use of advanced materials and designs, such as double-acting cylinders and multi-stage configurations, enhances the efficiency and durability of these components. Furthermore, the incorporation of seals and cushioning mechanisms reduces wear and tear, increasing the lifecycle of hydraulic systems. As industries push for greater efficiency and precision, the continuous evolution of hydraulic cylinder technology remains essential for optimizing performance in forging applications.

In the realm of forging, dies play a critical role in ensuring precision and efficiency in manufacturing processes. According to a report by the Forging Industry Association, nearly 80% of the quality of a forged part can be attributed to the die design and maintenance. This highlights the necessity of investing in high-quality dies and regularly maintaining them to preserve their effectiveness over time. Properly designed dies not only enhance the accuracy of each part produced but also significantly reduce material waste, contributing to more sustainable manufacturing practices.

Maintenance is equally essential, as improperly cared for dies can lead to defects and inconsistencies in the final product. Studies indicate that routine inspections and timely replacements of worn-out components can improve overall productivity by up to 25%. Regular maintenance routines, including cleaning, lubricating, and checking for signs of wear, can extend die life and ensure that forging operations remain within specified tolerances, thus guaranteeing that end products meet rigorous quality standards. By prioritizing the maintenance of dies, manufacturers can achieve optimal performance and enhance their competitiveness in the market.

| Part Name | Material | Function | Maintenance Tips | Impact on Performance |

|---|---|---|---|---|

| Die | Tool Steel | Shapes the metal during forging | Regular cleaning and inspection for wear | Ensures forging accuracy and surface finish |

| Punch | High Carbon Steel | Creates holes or shapes in forgings | Sharpen regularly and check for alignment | Impacts precision of holes and dimensional control |

| Anvil | Cast Iron | Provides a stable surface for forging | Keep clean and check for cracks | Stability affects accuracy of the forging process |

| Hammer | Alloy Steel | Applies force to the workpiece | Inspect regularly for damage and alignment | Inconsistent force can lead to defects |

| Bearing | Stainless Steel | Reduces friction in moving parts | Lubricate regularly and remove debris | Smooth movement enhances operational efficiency |

| Clamping Device | Aluminum | Holds the workpiece in place | Ensure tightness and check for wear | Stability during forging prevents errors |

| Feed Mechanism | Carbon Steel | Controls metal flow into the die | Regularly adjust for optimal flow | Proper flow improves consistency of forgings |

| Die Inserts | Tool Steel | Can be changed for different shapes | Replace when worn to maintain precision | Flexibility enhances productivity in designs |

| Cooling System | Copper | Regulates temperature of the die | Check for clogs and leaks regularly | Maintains die performance and extends life |

| Control System | Electronic components | Automates machine operations | Regular software updates and checks | Precision automation improves overall quality |

The article "Top 10 Forging Machine Parts You Must Know for Optimal Performance" delves into the essential components that ensure the efficiency and quality of forging operations. Key elements such as anvils are highlighted for their critical role in shaping materials during the forging process, while different types of forging presses are examined for their influence on product quality and overall operational efficiency.

Hydraulic cylinders are identified as vital components in high-performance forging machines, providing the necessary force for various applications. The significance of maintaining dies is also emphasized, as proper maintenance is crucial for ensuring forging accuracy. Additionally, the article explores the importance of control systems in modern forging equipment, illustrating how they enhance performance and reliability. Understanding these forging machine parts is key to achieving optimal results in any forging endeavor.