Leave Your Message

-

Phone

-

E-mail

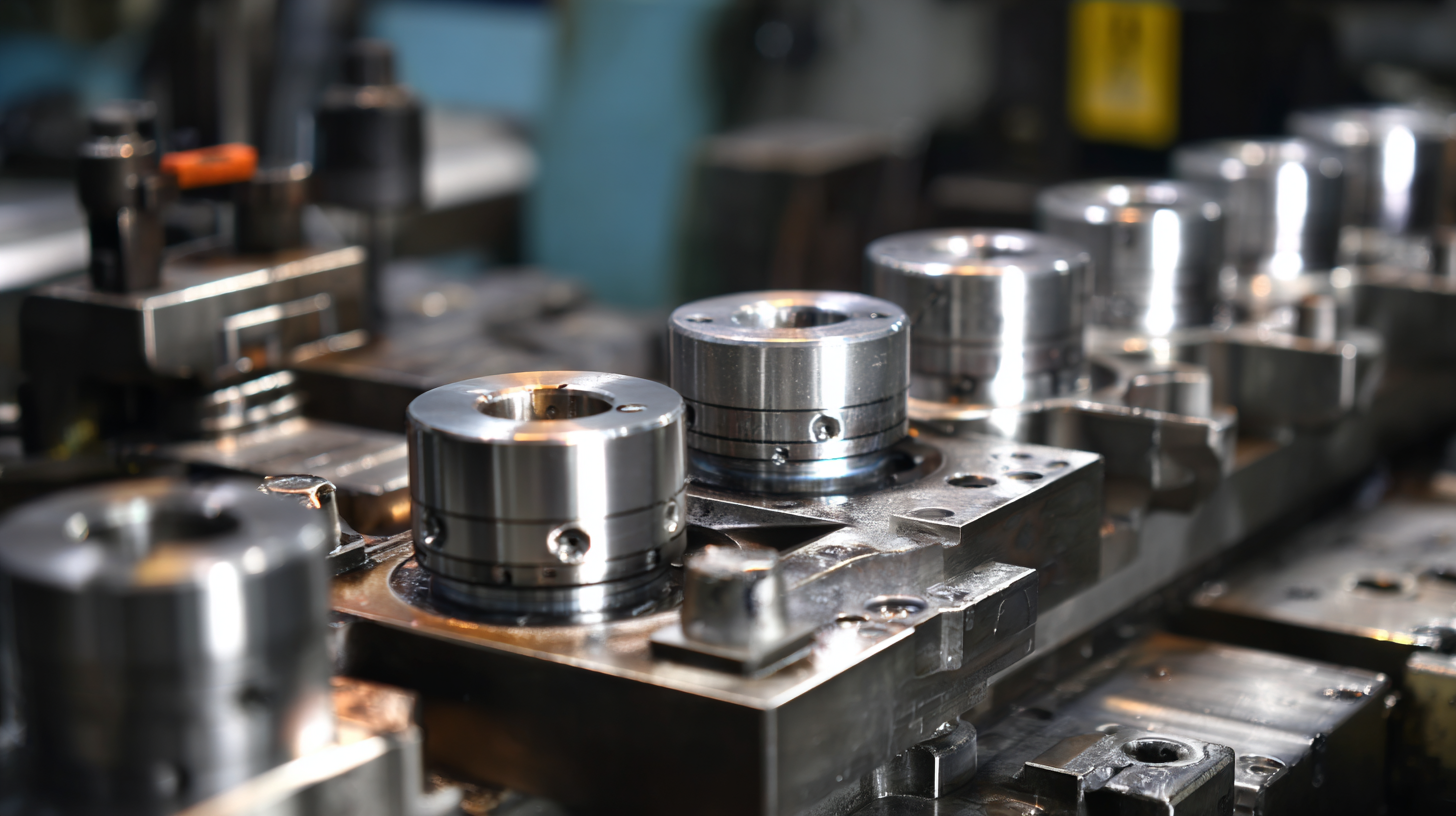

The global cold forging die market is witnessing significant growth, driven by the increasing demand for lightweight and high-strength components across various industries such as automotive, aerospace, and construction. According to a recent market analysis, the cold forging die segment is expected to expand at a CAGR of over 6% through 2025, emphasizing the need for effective procurement strategies to capitalize on this trend. Cold forging die technology enables manufacturers to create complex shapes with superior dimensional accuracy and surface finish while reducing material waste. As industries continue to emphasize efficiency and sustainability, understanding the intricacies of the cold forging die market becomes crucial for procurement professionals aiming to secure reliable and cost-effective solutions. This blog will delve into key insights about the market, emerging trends, and practical tips for successful procurement in the evolving landscape of cold forging dies.

The manufacturing of cold forging dies presents several key challenges that industry players must navigate to ensure efficiency and product quality. One significant challenge is the ability to withstand high-pressure loads during the forging process. Cold forging dies are typically produced using the shrink fit method, which enhances durability. However, even with robust construction, fatigue failure remains a persistent issue over time, necessitating careful monitoring and maintenance of die life cycles.

Moreover, the contemporary forging industry is under increasing pressure to adopt new technologies and efficiency practices. With the ongoing demand for energy savings and reduced environmental impact, manufacturers are exploring innovative energy-efficient methods in metal forming processes. Implementing smart systems for real-time monitoring of forging loads can significantly improve the lifespan of cold forging dies and optimize production processes. As the industry evolves, addressing these challenges will be crucial for ensuring long-term success and competitiveness in the metal forging market.

The global cold forging die market faces several common deficiencies that can impact production efficiency and product quality. As industries continue to adopt advanced forging technologies, addressing these deficiencies becomes crucial for sustained growth. Stakeholders in the cold forging sector must emphasize the importance of high-quality die manufacturing, as the market is projected to grow from $67.43 billion in 2024 to $94.88 billion by 2032, at a CAGR of 4.4%. This growth underscores the need for robust procurement strategies to combat challenges such as die wear, inadequate surface textures, and dimensional inaccuracies.

Recent studies highlight the significance of adopting innovative forging processes to enhance die performance. For instance, implementing cold-press forming methods can produce high-efficiency surface textures at lower costs. Additionally, research into multi-stage cold forging has demonstrated improvements in the mechanical properties of components, showing that dies designed for specific applications can reduce waste and increase overall productivity. By recognizing and addressing these common deficiencies, manufacturers can ensure the longevity and reliability of their forging dies, ultimately leading to better performance in the increasingly competitive market.

The material selection for cold forging dies plays a crucial role in determining their performance and longevity. According to a study by Research and Markets, the global cold forging die market is expected to grow significantly, driven by the increasing demand for high-performance components in the automotive and aerospace sectors. It is reported that using high-carbon and alloy steels can enhance wear resistance and toughness of the dies, allowing for better quality and precision in forged components.

Furthermore, the choice of material directly impacts the die's ability to withstand the high pressures and temperatures involved in the forging process. A recent industry analysis highlighted that the use of special coatings, such as titanium nitride (TiN) or chromium nitride (CrN), can increase the lifespan of cold forging dies by up to 50%, making them more cost-effective over time. As manufacturers seek to optimize production efficiency, understanding the relationship between die material and performance is essential for successful procurement and sustained competitive advantage.

The cold forging die market is witnessing significant advancements, but challenges remain that can impede successful procurement. One of the primary issues faced by manufacturers is the precision required in die design. According to a recent report by MarketsandMarkets, the global cold forging market is expected to grow from USD 5.5 billion in 2020 to USD 8.1 billion by 2025, underscoring the importance of effective procurement strategies. To overcome die design challenges, manufacturers should engage in collaborative design processes with their die suppliers, leveraging their expertise to achieve optimal results.

Another common issue is die wear, which can greatly affect production efficiency. Research indicates that the wear rate of cold forging dies can reach up to 30%, leading to increased production costs and downtime. Implementing advanced coating technologies and materials such as tungsten carbide can significantly enhance die longevity. Additionally, operators should invest in real-time monitoring systems to track die performance and preemptively identify wear patterns, ensuring that maintenance is conducted before any major disruptions occur. By addressing these critical issues proactively, companies can streamline their operations and improve their overall procurement strategies in the cold forging die market.

This chart displays the projected market size and growth rate of the Global Cold Forging Die Market from 2023 to 2025. The data illustrates the anticipated demand and provides insights into potential procurement strategies.

The quality and durability of cold forging dies are paramount for manufacturers aiming to meet increasing production demands and achieve optimal efficiency. To ensure that dies withstand the rigors of manufacturing processes, it is essential to implement best practices during procurement. Firstly, selecting the right materials is crucial; dies made from high-quality steel or specialized alloys are more likely to resist wear and deformation, extending their functional lifespan.

Moreover, meticulous attention to design and engineering is necessary. Advanced simulation technologies can help in identifying stress points and optimizing die geometries before production begins. Regular maintenance and inspections also play a significant role in prolonging the life of dies, enabling manufacturers to foresee potential issues and address them proactively. By prioritizing these practices, companies can enhance the overall productivity of their operations while minimizing unexpected downtime caused by equipment failure.

| Dimension | Value |

|---|---|

| Market Size (USD Million) | 450.5 |

| CAGR (2021-2025) | 6.2% |

| Key Applications | Automotive, Aerospace, Electronics |

| Main Materials Used | Steel, Aluminum, Brass |

| Top Regions | North America, Europe, Asia-Pacific |

| Quality Assurance Practices | Regular Inspection, Testing, and Certification |

| Durability Factors | Material Hardness, Heat Treatment, Die Design |