Leave Your Message

-

Phone

-

E-mail

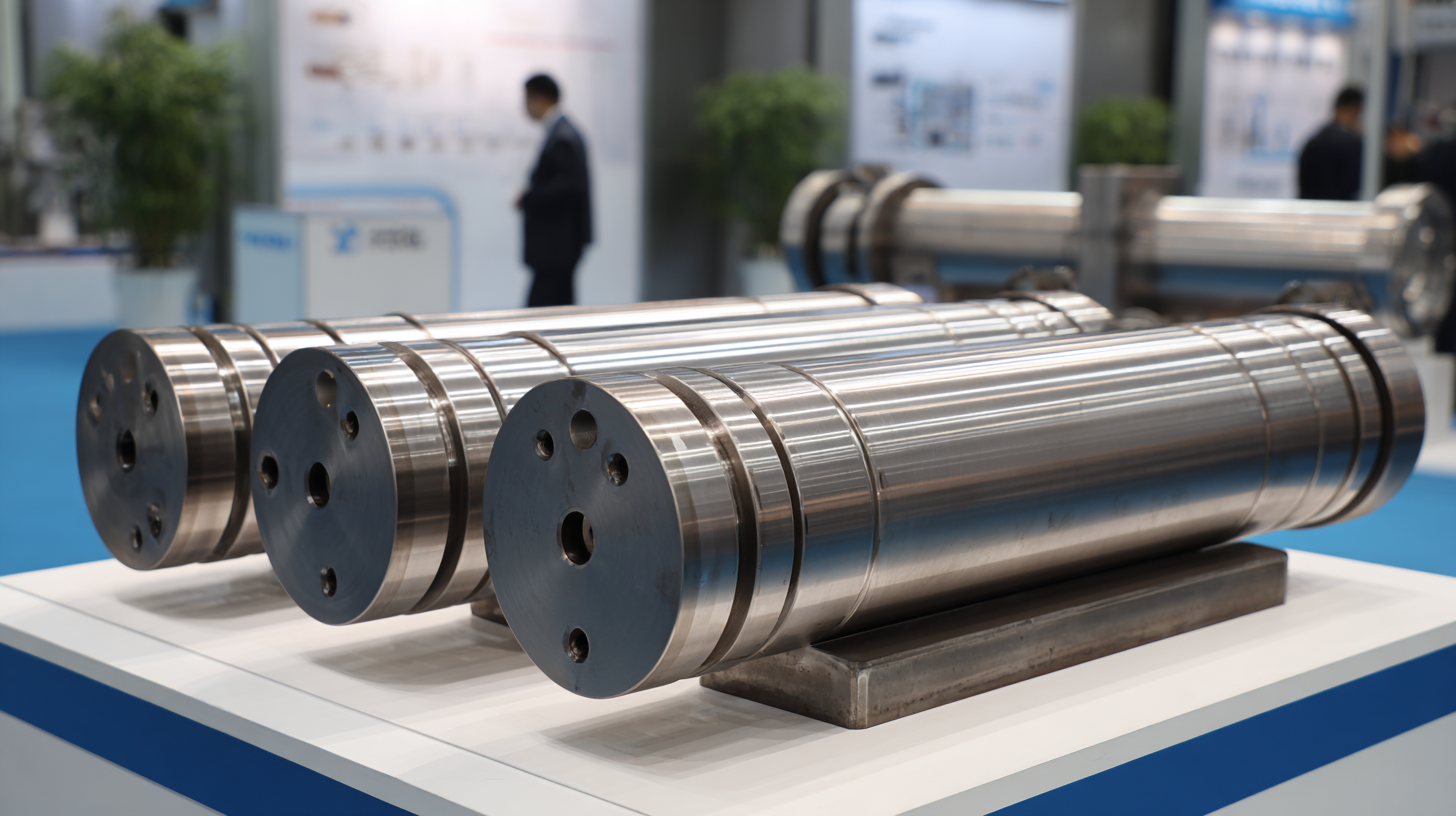

The 138th China Import and Export Fair in 2025 presents a pivotal opportunity to explore emerging trends in the forged cylinders industry, which has shown robust growth driven by increasing demand across various sectors. According to a recent market research report, the global forged cylinders market is projected to reach approximately USD 4.5 billion by 2027, expanding at a CAGR of 5.1% from 2022. This growth can be attributed to the rising adoption of forged components in automotive, aerospace, and manufacturing industries due to their enhanced durability and strength. As manufacturers continue to innovate and improve production processes, the focus on sustainability and lightweight materials showcases the industry's response to evolving consumer expectations. The fair will serve as a crucial platform for stakeholders to exchange insights, establish business partnerships, and showcase advancements in technology and design for forged cylinders, ultimately shaping the future landscape of this dynamic market.

The 138th China Import and Export Fair in 2025 is set to showcase groundbreaking advancements in the forged cylinder manufacturing sector. Emerging innovations are not just enhancing production efficiency but also addressing the industry's pressing challenges. According to a recent market analysis by ResearchAndMarkets, the global forged cylinder market is projected to grow at a CAGR of 4.5% from 2023 to 2030, driven by the increasing demand in automotive and aerospace applications. This growth opens up opportunities for manufacturers to adopt advanced techniques such as precision forging and smart manufacturing, which utilize AI and automation to optimize production processes.

Tips: As manufacturers look to innovate, investing in research and development is crucial. Keeping abreast of emerging technologies like additive manufacturing can also provide a competitive edge. Moreover, attending industry fairs, such as the upcoming event in China, can facilitate networking and collaboration, which are vital for staying ahead in a rapidly evolving market.

Another exciting area is the integration of sustainable practices in the forging process. The use of recycled materials in forge manufacturing and energy-efficient production techniques are gaining traction. Reports indicate that companies adopting green technologies see a significant reduction in production costs, with savings of up to 30%. Embracing these innovations not only benefits the environment but also enhances brand reputation and customer loyalty.

The demand for forged cylinders in 2025 is anticipated to be significantly influenced by several market dynamics, particularly within the automotive and industrial sectors. As automobile manufacturers focus on enhancing engine efficiency and performance, the need for high-quality components like forged cylinders is surging. The market analysis indicates a robust growth trajectory, with projections suggesting a continued rise alongside advancements in manufacturing technologies and increased investments in research and development.

Moreover, the automotive balance shaft market's growth, which is valued at over USD 15 billion, reflects a broader trend impacting the forged cylinder sector. The push for lightweight and durable materials is driving manufacturers to adopt forging processes, thereby improving strength and performance. Additionally, the sustainability initiatives within the industry are directing attention towards more responsible sourcing and manufacturing practices, shaping the demand for forged products that meet both regulatory and consumer expectations. These trends collectively portray a vibrant and evolving landscape for forged cylinders in 2025.

The 138th China Import and Export Fair in 2025 is set to spotlight critical sustainability trends within the forged cylinder industry. As environmental awareness grows, manufacturers are increasingly adopting eco-friendly practices. According to a recent report by MarketsandMarkets, the global market for sustainable manufacturing is projected to reach $420 billion by 2027, with a compound annual growth rate (CAGR) of 8.5%. This shift reflects a broader movement towards reducing carbon footprints and utilizing sustainable materials in production processes.

In the forged cylinder sector, innovations like the adoption of recycled metals and energy-efficient forging techniques are becoming commonplace. A study from the International Journal of Advanced Manufacturing Technology highlights that companies implementing these practices have already reduced emissions by up to 30%. Furthermore, integrating sustainable design principles not only meets regulatory demands but also enhances product lifecycle, which aligns with the growing consumer preference for environmentally responsible products. As manufacturers gather at the 138th China Import and Export Fair, they will have the opportunity to share insights, showcase advancements, and collaborate on solutions that prioritize sustainability in forged cylinder production.

| Trend | Description | Impact (1-5) | Adoption Rate (%) |

|---|---|---|---|

| Eco-friendly Materials | Increased use of recyclable and sustainable materials in cylinder manufacturing. | 4 | 65 |

| Energy-efficient Processes | Adopting manufacturing techniques that reduce energy consumption. | 5 | 70 |

| Carbon Footprint Reduction | Strategies aimed at reducing overall emissions during production. | 5 | 60 |

| Circular Economy Practices | Implementing closed-loop systems to minimize waste. | 4 | 50 |

| Digital Transformation | Using advanced technologies for improved efficiency and tracking. | 3 | 55 |

The 138th China Import and Export Fair serves as a pivotal platform for the presentation of forged cylinder innovations, attracting prominent manufacturers and suppliers from around the globe. This year, industry leaders are showcasing their latest advancements and technologies designed to enhance the efficiency and durability of forged cylinders. Major players in the sector are emphasizing sustainable manufacturing practices and the integration of smart technologies to meet the evolving demands of various applications, ranging from automotive to aerospace.

A dynamic competitive landscape has emerged, characterized by both established firms and emerging startups vying for market share. Key players, including renowned manufacturers, are leveraging strategic partnerships and investments in R&D to differentiate their offerings. Notable discussions at the fair are expected to revolve around the adoption of advanced materials and the trends influencing pricing and supply chain dynamics. As the industry continues to innovate, the insights gained at this event will be crucial for stakeholders looking to navigate the complex market of forged cylinders.

The forged cylinder sector is poised for significant developments beyond 2025, shaped by technological advancements and changing market dynamics. As industries increasingly prioritize sustainability, the demand for lightweight and durable materials is expected to surge. Manufacturers will need to invest in innovative forging processes and smart manufacturing solutions to optimize production efficiency and reduce waste, thus meeting the evolving needs of various applications from automotive to aerospace.

Tips for staying ahead in the forged cylinder market include keeping an eye on emerging technologies such as AI-driven predictive maintenance and automated quality control systems. These innovations can enhance operational workflows, ensuring that manufacturers maintain a competitive edge. Additionally, forming strategic partnerships with suppliers and research institutions can foster collaboration, leading to the development of cutting-edge materials that meet the highest standards of performance and environmental responsibility.

Moreover, as globalization continues to influence trade, understanding international market trends will be crucial. Companies should actively seek insights into regional demands and regulatory changes to create tailored solutions that align with customer expectations and compliance requirements. By preparing for these shifts, businesses can establish themselves as leaders in the evolving landscape of forged cylinders.