Leave Your Message

-

Phone

-

E-mail

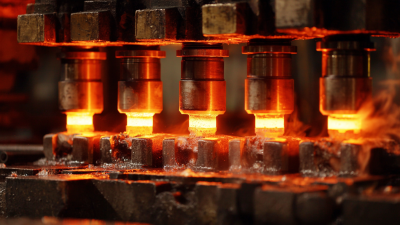

In today's rapidly evolving industrial landscape, the adoption of cutting-edge technologies and materials is crucial for enhancing efficiency and performance. Among these materials, Forged Steel Parts stand out due to their exceptional strength, durability, and versatility. As manufacturers seek innovative solutions to meet the demands of modern applications, the creative utilization of forged steel components has paved the way for advancements across various industries, including automotive, aerospace, and construction. This blog will explore a comprehensive checklist of the innovative applications of forged steel parts in contemporary industry settings, highlighting their unique benefits and the transformative impact they have on production processes. By examining these applications, we aim to showcase how forged steel parts not only optimize performance but also contribute to sustainability and cost-effectiveness, solidifying their role as a cornerstone of modern manufacturing practices.

Forged steel parts have become essential in various modern industries due to their superior strength and durability compared to casted alternatives. The manufacturing process of these components involves heating solid blocks of steel to a malleable temperature before shaping them through various methods such as open-die forging, closed-die forging, and ring rolling. According to a report by Grand View Research, the global market for forged steel is expected to reach USD 165.7 billion by 2025, with an annual growth rate of approximately 5.6%. This growth is largely driven by the demand for forged components in automotive, aerospace, and construction sectors, where structural integrity and reliability are paramount.

In the realm of manufacturing, the essential processes like heating, shaping, and cooling play a critical role in enhancing the mechanical properties of forged steel. The forging process allows for finer grain structure, leading to improved toughness and fatigue resistance. A study published in the Journal of Materials Engineering and Performance highlights that forged steel components demonstrate 20-30% higher fatigue resistance compared to non-forged equivalents. These attributes are why industries are increasingly leaning towards forged steel parts in their designs, securing an advantage in performance and longevity.

Forged steel parts are increasingly becoming a cornerstone in modern industrial applications, and their advantages are noteworthy. The robust nature of forged steel lends itself to enhanced strength and durability, making it a top choice for critical components in sectors like automotive and aerospace. This unique manufacturing process not only improves material integrity but also allows for precise control over mechanical properties, which is essential for high-performance applications.

Forged steel parts are increasingly becoming a cornerstone in modern industrial applications, and their advantages are noteworthy. The robust nature of forged steel lends itself to enhanced strength and durability, making it a top choice for critical components in sectors like automotive and aerospace. This unique manufacturing process not only improves material integrity but also allows for precise control over mechanical properties, which is essential for high-performance applications.

Tips for leveraging forged steel in your projects include conducting a thorough assessment of the operating conditions your components will face. Ensure that the design accounts for the load requirements and environmental factors. Additionally, collaborating with experienced manufacturers who specialize in forging can provide insights into optimizing your designs for efficiency and cost-effectiveness.

As industries embrace advances in technology, the growth of the forging market is projected to rise significantly. Innovations such as Artificial Intelligence (AI) are shaping trends and driving the adoption of forged steel by highlighting its impact compared to traditional fabrication methods. Emphasizing the adoption of forged parts can lead to improvements in production efficiency and product reliability, ultimately benefiting your industrial applications.

The innovative applications of forged steel parts span across various industries, highlighting their critical role in modern manufacturing. According to recent market analysis, the U.S. metal forging market is projected to witness significant growth, with estimates suggesting an increase in value as industries like automotive, aerospace, and defense continue to demand high-strength materials. By 2033, the North American forging market is expected to expand considerably, driven by the need for durable and lightweight components to optimize performance and reduce emissions.

In particular, carbon and alloy steel forgings are essential in applications requiring exceptional resilience and machinability. The advancements in machining and welding technologies further amplify the potential of forged steel parts in meeting stringent industry standards. Innovative approaches, such as in-situ friction stir forging, present groundbreaking methods for gear fabrication, showcasing the versatility of forged materials. With a focus on sustainability, these techniques not only enhance productivity but also aim to minimize waste, aligning with the industry’s shift towards greener manufacturing practices. As the market evolves, the incorporation of cutting-edge methods and materials will undoubtedly shape the future of various sectors reliant on stainless steel, titanium, and beyond.

This chart illustrates the distribution of forged steel part applications across various industries, showcasing their significance and demand in today's market.

When comparing forged steel to other materials such as cast iron, aluminum, and plastics, several key advantages come to light. Forged steel, known for its exceptional strength-to-weight ratio, offers a durability that is often unmatched. Unlike cast iron, which can be brittle, forged steel components can withstand significant stress and impact, making them ideal for high-demand applications like automotive parts and aerospace components. This resilience translates into longer service life and reduced maintenance costs, essential factors in today’s competitive manufacturing landscape.

On the other hand, while materials like aluminum are lighter and potentially more cost-effective for certain applications, they often lack the strength of forged steel. Additionally, the thermal and electrical conductivity of aluminum may be beneficial in specific scenarios, but when it comes to load-bearing capabilities, forged steel reigns supreme. Plastics, while versatile and lightweight, do not provide the same level of strength, especially under extreme conditions. Ultimately, the choice between forged steel and other materials hinges on the specific demands of the application, but for projects requiring high strength and reliability, forged steel remains a leading choice in modern industry.

| Material Type | Tensile Strength (MPa) | Ductility (%) | Weight (kg/m³) | Cost (USD per kg) |

|---|---|---|---|---|

| Forged Steel | 600-1200 | 10-20 | 7850 | 2.00 |

| Cast Iron | 250-400 | 1-3 | 7200 | 1.50 |

| Aluminum Alloy | 300-700 | 12-35 | 2700 | 3.00 |

| Titanium Alloy | 900-1200 | 8-15 | 4500 | 8.00 |

| Composite Materials | 200-500 | 5-15 | 1500 | 5.00 |

As industries evolve, the future trends in forged steel technology are set to shape manufacturing paradigms significantly. According to a recent report by the Global Forging Market Analysis, the global market for forged steel is predicted to reach approximately $72 billion by 2025, driven by increased demands in automotive and aerospace industries. This growth is due, in part, to the development of advanced forging techniques that enhance material properties and enable the production of lighter, yet stronger components.

Moreover, the adoption of automation and digital technologies in forging processes is transforming the landscape, allowing companies to improve efficiency and reduce waste. The integration of smart manufacturing and the Internet of Things (IoT) into forging operations is expected to increase productivity by as much as 20%. As industries aim for sustainability, the shift towards using recycled materials in forging could diminish carbon footprints by 15-25%, highlighting a pivotal movement toward eco-friendly practices. These trends not only promise enhanced performance and cost-effectiveness but also contribute to a more sustainable industrial future.