Leave Your Message

-

Phone

-

E-mail

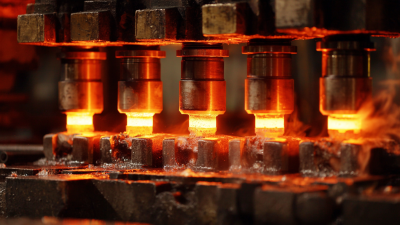

In the highly competitive landscape of manufacturing, the optimization of production processes is critical for enhancing efficiency and reducing costs. One key component in this arena is the Cold Heading Die, which plays a central role in shaping and forming metal parts with precision and speed. According to a recent report by the International Association of Die and Mould Technology (IADMT), the global market for cold heading products is expected to reach $30 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.2%. This underscores the growing demand for innovative solutions that enhance die performance and longevity, ultimately impacting product quality and production speed. As manufacturers seek to adopt advanced techniques to improve the functionality and durability of their Cold Heading Dies, exploring cutting-edge materials, coatings, and design modifications becomes essential to staying ahead in the market.

The performance of cold heading dies is critical to the efficiency and quality of manufacturing processes. According to a recent report from the Precision Metalforming Association (PMA), optimizing die performance can lead to a reduction in production costs by up to 30%. One of the key factors influencing this performance is the material composition of the dies themselves. High-speed steels and carbide materials are commonly used due to their exceptional hardness and wear resistance, but the choice of coating can also significantly impact durability. For instance, titanium nitride (TiN) coatings have been shown to enhance die life by as much as 50% compared to uncoated versions.

Another influential aspect is the design and manufacturing precision of the dies. A study by the International Journal of Advanced Manufacturing Technology highlights that dies with improved geometric accuracy can result in lower reject rates and reduced scrap material, ultimately enhancing overall productivity. Additionally, factors such as heat treatment processes and surface finishing techniques also play a pivotal role in ensuring optimal die performance and longevity. By focusing on these critical elements, manufacturers can significantly improve the operational efficiency of their cold heading processes.

| Factor | Description | Impact on Performance | Optimization Strategies |

|---|---|---|---|

| Material Quality | The grade of steel used in die manufacturing | High | Use premium raw materials |

| Heat Treatment | Process of heating and cooling die material | Medium | Implement advanced heat treatment techniques |

| Die Design | Shape and geometry of the cold heading die | High | Adopt CAD simulations for optimal design |

| Lubrication | Fluids used to reduce friction during operation | Medium | Select the right lubrication materials |

| Manufacturing Precision | Accuracy in die production | High | Utilize precision machining technologies |

In the competitive field of manufacturing, the durability of cold heading dies plays a pivotal role in ensuring both efficiency and quality. The introduction of advanced materials has transformed die manufacturing, offering enhanced resistance to wear and tear. High-performance alloys, such as tool steels and carbide composites, are now being utilized to extend the life cycle of dies, reducing downtime and operational costs.

When considering materials for die production, it’s essential to select options that not only withstand high-pressure environments but also maintain their structural integrity under extreme conditions. One tip is to evaluate the mechanical properties of potential materials, focusing on hardness, toughness, and corrosion resistance. Another critical consideration is the heat treatment processes; optimizing these can improve the material’s lifecycle significantly.

Integrating coatings, such as titanium nitride or diamond-like carbon, can further elevate die performance. These coatings provide additional protection against friction and wear, ensuring smoother operations. Manufacturers should consistently assess the latest advancements in coatings and material composites to stay ahead in a constantly evolving market.

In the competitive landscape of manufacturing, enhancing the lifespan of cold heading dies has become paramount for operational efficiency and cost-effectiveness. Innovative coatings and treatments are emerging as game changers in this arena. For instance, studies show that specialized coatings, such as titanium nitride (TiN) and chromium nitride (CrN), can significantly improve wear resistance. According to a report by the American Society for Metals, TiN-coated dies can extend operational life by up to 50%, greatly reducing the frequency of die replacements and maintenance downtime.

Moreover, advanced thermal treatments, such as nitriding or carburizing, have proven effective in augmenting die durability. Research indicates that these processes can enhance surface hardness by over 20% compared to untreated dies. In an industry where precision and longevity are critical, these treatments not only extend the lifespan of dies but also maintain their performance integrity under rigorous operating conditions.

By adopting these innovative solutions, manufacturers can achieve lower production costs while improving product quality, thus driving greater profitability in the long run.

In the realm of manufacturing, the efficiency and longevity of cold heading dies are critical to production success. Implementing predictive maintenance strategies for die management can significantly enhance this performance, minimizing downtime and reducing costs.

By utilizing advanced analytics and real-time monitoring, manufacturers can gain insight into the operational status of dies, predicting failures before they occur. This proactive approach not only extends the lifespan of the dies but also ensures that production schedules remain uninterrupted.

By utilizing advanced analytics and real-time monitoring, manufacturers can gain insight into the operational status of dies, predicting failures before they occur. This proactive approach not only extends the lifespan of the dies but also ensures that production schedules remain uninterrupted.

Furthermore, predictive maintenance allows for the optimization of maintenance schedules, aligning them with actual usage and wear patterns rather than relying on fixed intervals. This data-driven methodology enables manufacturers to allocate resources more efficiently, focusing efforts where they are most needed.

Moreover, integrating these predictive strategies fosters a culture of continuous improvement, encouraging teams to innovate and adapt to the findings of their monitoring systems. Ultimately, embracing predictive maintenance transforms die management into a more strategic component of manufacturing, paving the way for enhanced operational performance and product quality.

In the modern manufacturing landscape, leveraging technology for real-time monitoring of cold heading die performance is transforming operational efficiency. Industry reports indicate that manufacturers adopting real-time monitoring systems can enhance die lifespan by up to 30%. This improvement not only reduces downtime for repairs but also leads to significant cost savings. By integrating IoT (Internet of Things) sensors, manufacturers can constantly collect data on die temperature, pressure, and wear, allowing them to preemptively address issues before they escalate.

Tip: Implement a predictive maintenance schedule using real-time data analytics to extend the lifecycle of your cold heading dies. This proactive approach can save your facility approximately 20% in maintenance costs annually.

Furthermore, real-time monitoring facilitates the immediate identification of anomalies in die performance. According to a recent study, companies employing such technology reported a 25% reduction in defect rates. Automated alerts can notify operators of deviations from optimal operating conditions, enabling quick interventions that maintain product quality and consistency.

Tip: Train your workforce to utilize real-time data effectively, ensuring they can make informed decisions rapidly. This investment in training can lead to a notable increase in productivity and quality assurance processes.