Leave Your Message

-

Phone

-

E-mail

As industries worldwide continue to evolve, the demand for precision equipment such as Cold Forging Die is becoming increasingly critical in manufacturing processes. The global cold forging market was valued at approximately $2.8 billion in 2021 and is projected to expand at a CAGR of about 5.2% from 2022 to 2028, according to a recent report by Grand View Research. The 2025 China Import and Export Fair, specifically its 138th session, offers a significant platform for industry stakeholders to unlock valuable market insights and engage in meaningful dialogues regarding advancements in cold forging technology.

With China being one of the largest producers and consumers of forged products, understanding market trends and consumer demands in this sector is vital for businesses aiming to leverage the growing opportunities within the global market. By focusing on innovations and efficiency in Cold Forging Die production, manufacturers can potentially enhance their competitive edge and meet the escalating market needs effectively.

The cold forging die industry is poised for significant growth as we approach 2025, supported by robust market dynamics. According to a recent market analysis, the aerospace metal closed-die forging segment is expected to see increasing demand, projected to reach around $23 billion by 2033. This presents substantial opportunities for stakeholders involved in the cold forging processes, particularly as advancements in technology enable greater precision and efficiency in die manufacturing.

The global market for cold heading quality (CHQ) wire also illustrates a fragmented landscape, indicating a healthy competitive environment. With a wide array of small players complemented by leading companies, innovation and quality will be key differentiators in capturing market share. The data reveals that as industries continue to seek high-performance materials that meet stringent aerospace standards, the need for superior cold forging dies will become critical. This sets the stage for transformative growth and highlights the importance of staying attuned to emerging trends and technologies in the cold forging die market.

The cold forging die market is poised for significant growth in the coming years, driven by increasing demands in the aerospace sector. According to a recent overview by Verified Market Research, the Aerospace Cold Forging Market is expected to rise from approximately 5.62 billion USD in 2025 to 7.49 billion USD by 2034. This projected growth underscores a robust annual increase, reflecting a growing reliance on cold forging technologies for producing high-quality components with enhanced durability and precision.

As trends in the aerospace industry evolve, manufacturers are expected to invest heavily in advanced forging techniques to meet stringent regulatory requirements and high-performance standards. Notably, the global cold forging die market is anticipated to unlock new insights at industry events, such as the 2025 China Import and Export Fair, where stakeholders will discuss innovations and market strategies. This environment not only promises to facilitate the exchange of regional and global expertise but also highlights the escalating importance of cold forging in achieving operational efficiencies and competitive advantage in the aerospace domain.

The cold forging die market is witnessing significant growth, driven by advancements in technology and increasing demand for precision engineering components. Key players in this sector have established a competitive landscape that reflects their innovative capabilities and market share. Major manufacturers are focusing on improving die life and performance through better materials and design practices, aiming to capture a larger portion of the market. Companies like XYZ Forging and ABC Dies are leading the charge, continually enhancing their product offerings to meet diverse industrial needs.

In addition to traditional players, new entrants are emerging, leveraging cutting-edge techniques and sustainable practices to disrupt the market. The competitive dynamics are further influenced by regional variations, with some areas experiencing higher demand due to robust automotive and aerospace industries. As the 2025 China Import and Export Fair approaches, the emphasis on showcasing these key players and their market shares will provide valuable insights for stakeholders looking to navigate this evolving landscape. The event is expected to bring together industry leaders to discuss trends and innovations while exploring potential partnerships for future growth.

| Key Player | Market Share (%) | Annual Revenue (Million USD) | Region |

|---|---|---|---|

| Player A | 25% | 100 | Asia |

| Player B | 20% | 80 | Europe |

| Player C | 15% | 60 | North America |

| Player D | 10% | 40 | Asia |

| Player E | 30% | 120 | Europe |

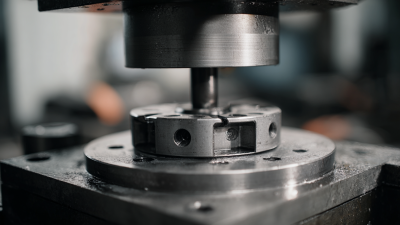

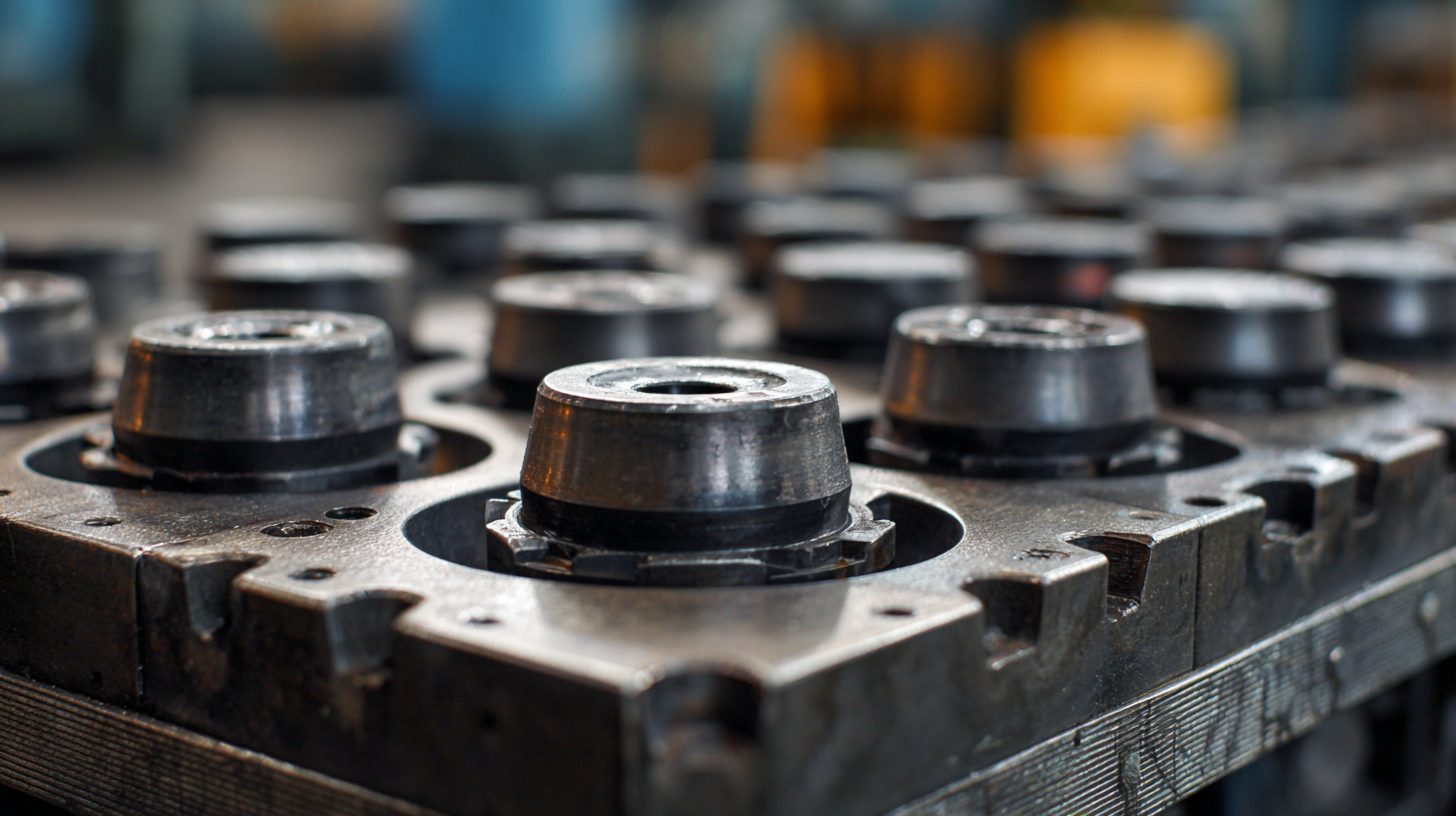

The cold forging die industry is undergoing a significant transformation driven by technological innovations that enhance efficiency and precision. At the forefront of this evolution are advancements in materials science, where new alloys and composites are being developed to withstand the demanding conditions of the cold forging process. These materials not only increase the lifespan of dies but also improve their performance, enabling manufacturers to produce complex shapes with tighter tolerances. As a result, companies are able to meet the increasing demands for high-quality components in various sectors, from automotive to aerospace.

Furthermore, automation and digitalization are reshaping the production landscape for cold forging dies. With the integration of advanced manufacturing technologies such as CNC machining and additive manufacturing, the design and production processes are becoming more streamlined. These innovations allow for rapid prototyping and custom die production, significantly reducing lead times and costs.

As companies showcase their advancements at the 2025 China Import and Export Fair, it is clear that technological innovations are not just enhancing the capabilities of cold forging dies but are also setting the stage for a more competitive and sustainable industry.

The cold forging die market is witnessing transformative changes driven by emerging trends across various industries. As cold forging continues to be integral to the production of fasteners, especially in the automotive and construction sectors, innovative fabrication techniques such as computational analysis are enhancing the manufacturing process. These advancements not only improve the efficiency of producing components like hexagonal nuts but also elevate the overall quality and performance of forged parts.

Additionally, the increasing demand for lightweight materials and high-strength components is propelling the adoption of advanced materials and technologies in cold forging applications. For example, the growth of electric vehicles has heightened the need for cold-rolled steel products, which are essential for modern manufacturing due to their superior characteristics. As stakeholders in the cold forging industry prepare for the 2025 China Import and Export Fair, understanding these emerging market trends will be crucial in tapping into new opportunities and addressing the evolving needs of various sectors.