Leave Your Message

-

Phone

-

E-mail

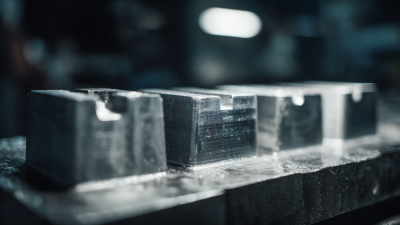

In the competitive landscape of manufacturing, the optimization of the Cold Forging Die is crucial for enhancing production efficiency and reducing operational costs. Recent industry reports reveal that cold forging processes can achieve up to 80% tooling life improvement and a 30% increase in part accuracy compared to traditional methods. By refining die design and utilizing advanced materials, manufacturers can significantly reduce scrap rates—often reported at an impressive reduction of 50%—while speeding up production cycles. As the global demand for high-strength, lightweight components continues to rise, implementing strategies to optimize Cold Forging Dies becomes increasingly vital. This not only supports the lean manufacturing initiatives but also aligns with sustainability goals, making it essential for industry leaders to focus on innovative approaches in die optimization for achieving maximum efficiency.

In the competitive landscape of manufacturing, the optimization of the Cold Forging Die is crucial for enhancing production efficiency and reducing operational costs. Recent industry reports reveal that cold forging processes can achieve up to 80% tooling life improvement and a 30% increase in part accuracy compared to traditional methods. By refining die design and utilizing advanced materials, manufacturers can significantly reduce scrap rates—often reported at an impressive reduction of 50%—while speeding up production cycles. As the global demand for high-strength, lightweight components continues to rise, implementing strategies to optimize Cold Forging Dies becomes increasingly vital. This not only supports the lean manufacturing initiatives but also aligns with sustainability goals, making it essential for industry leaders to focus on innovative approaches in die optimization for achieving maximum efficiency.

Optimizing cold forging die performance is crucial for maximizing efficiency in manufacturing. Several key factors influence this performance, including die material selection, heat treatment processes, and geometrical design. Recent studies indicate that high-quality tool steels can significantly enhance the lifespan of dies, reducing costs and downtime associated with frequent replacements. Additionally, incorporating advanced heat treatment methods can improve wear resistance, allowing for better retention of die integrity during high-stress operations.

Tips: To optimize die performance, consider conducting regular assessments of die wear and tear, which can facilitate early detection of potential issues. Furthermore, adopting in-process monitoring strategies, such as measuring force and temperature, can lead to real-time adjustments that maximize performance and ensure product consistency.

Moreover, the importance of geometry in die design cannot be overstated. Research has shown that optimizing the shape and alignment can lead to enhanced flow of material, thereby reducing scrap rates and improving overall efficiency. Investing in simulation software to analyze die behavior under different conditions can also assist manufacturers in developing robust designs that meet production needs.

When optimizing your cold forging die, selecting the right materials is crucial for enhancing both durability and efficiency. High-performance materials can withstand the extreme pressures and temperatures generated during the forging process. Steel alloys, such as D2 or S7, are often favored for their toughness and wear resistance. Additionally, incorporating surface treatments like nitriding or carbide coating can significantly increase the lifespan of your die.

**Tips:** Consider the trade-offs between cost and performance when choosing materials. While high-end alloys may come with a higher price tag, their long-term performance can lead to lower maintenance costs and greater production efficiency. Always evaluate the specific requirements of your application, such as the type of metal being forged and the complexity of the die design.

Another key factor is the die's geometry, which should align with the selected material's properties. An optimized design can help reduce stress concentrations and improve load distribution, leading to improved efficiency.

**Tips:** Conduct thorough simulations to assess how different materials perform under operational conditions. Utilizing advanced software can help refine your design before physical production, ensuring that the final die maximizes performance.

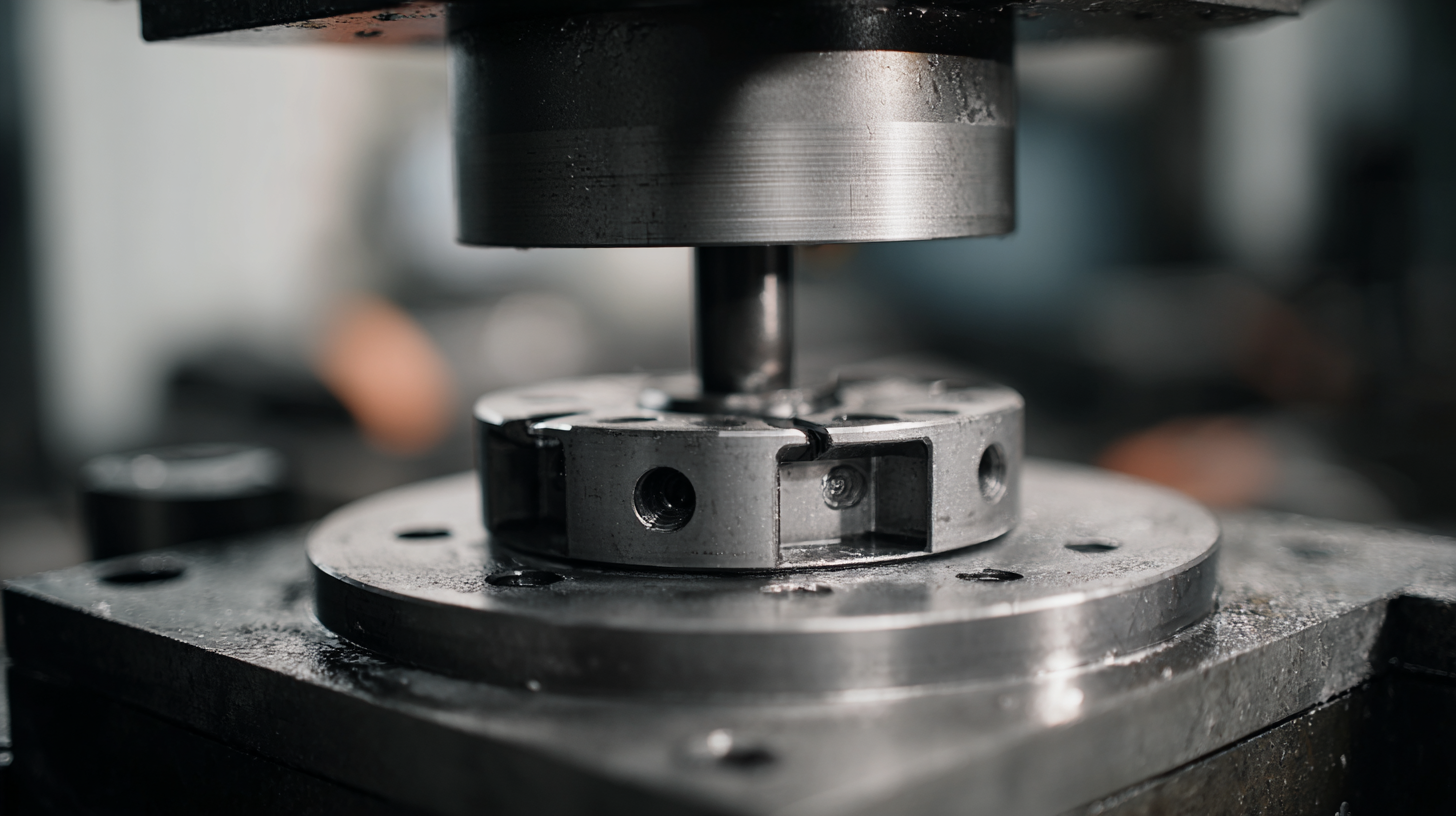

Implementing advanced design techniques for optimal die geometry is crucial in maximizing the efficiency of cold forging processes. The shape and structure of the die play a significant role in determining the material flow, minimizing defects, and ensuring uniform deformation during the forging operation. Utilizing Computer-Aided Design (CAD) software allows engineers to simulate various die geometries and analyze stress distribution, which is vital for identifying the best configuration that enhances performance while minimizing wear.

Moreover, incorporating innovative design features such as variable profile dies, cooling channels, and improved surface finishes can significantly boost productivity. Variable profile dies can adapt to different material flow characteristics, reducing the likelihood of fractures and ensuring a more consistent final product. Cooling channels designed within the die help to dissipate heat effectively, maintaining optimal temperature conditions and extending die life. By focusing on these advanced design strategies, manufacturers can achieve greater efficiency, reduce production costs, and enhance the overall quality of cold-forged components.

| Design Parameter | Impact on Efficiency | Optimization Technique |

|---|---|---|

| Die Geometry | Affects material flow and final part accuracy | Use CAD software for precise modeling |

| Material Selection | Influences die wear and part quality | Choose high-strength tool steel |

| Heat Treatment | Enhances durability and performance | Implement tempering and quenching processes |

| Surface Finish | Reduces friction and enhances life span | Use surface hardening techniques |

| Cooling Channels | Affects cycle time and heat distribution | Design efficient cooling pathways |

Maintaining cold forging dies is crucial for maximizing efficiency and extending their lifespan. One of the best practices is to establish a routine maintenance schedule. Regular inspections can help identify wear and tear early, preventing more extensive damage and costly downtimes. This proactive approach ensures that the dies operate at optimal performance levels, enhancing overall production efficiency.

Tips: Ensure that you clean the dies thoroughly after each use. Residues can accumulate and cause defects in the finished products. Also, consider using appropriate lubricants to minimize friction during the forging process, which can lead to premature wear of the dies.

Another essential practice is to monitor the operating temperatures and pressures. Excessive heat or pressure can negatively impact the die life, so maintaining the correct parameters is vital. Implementing a temperature tracking system can provide real-time data, allowing for quick adjustments when needed.

Tips: Invest in high-quality cooling systems to dissipate heat efficiently. This can significantly reduce thermal stress on the dies. Regularly reviewing operational metrics will also support informed decisions about adjustments to processes that may affect die longevity.

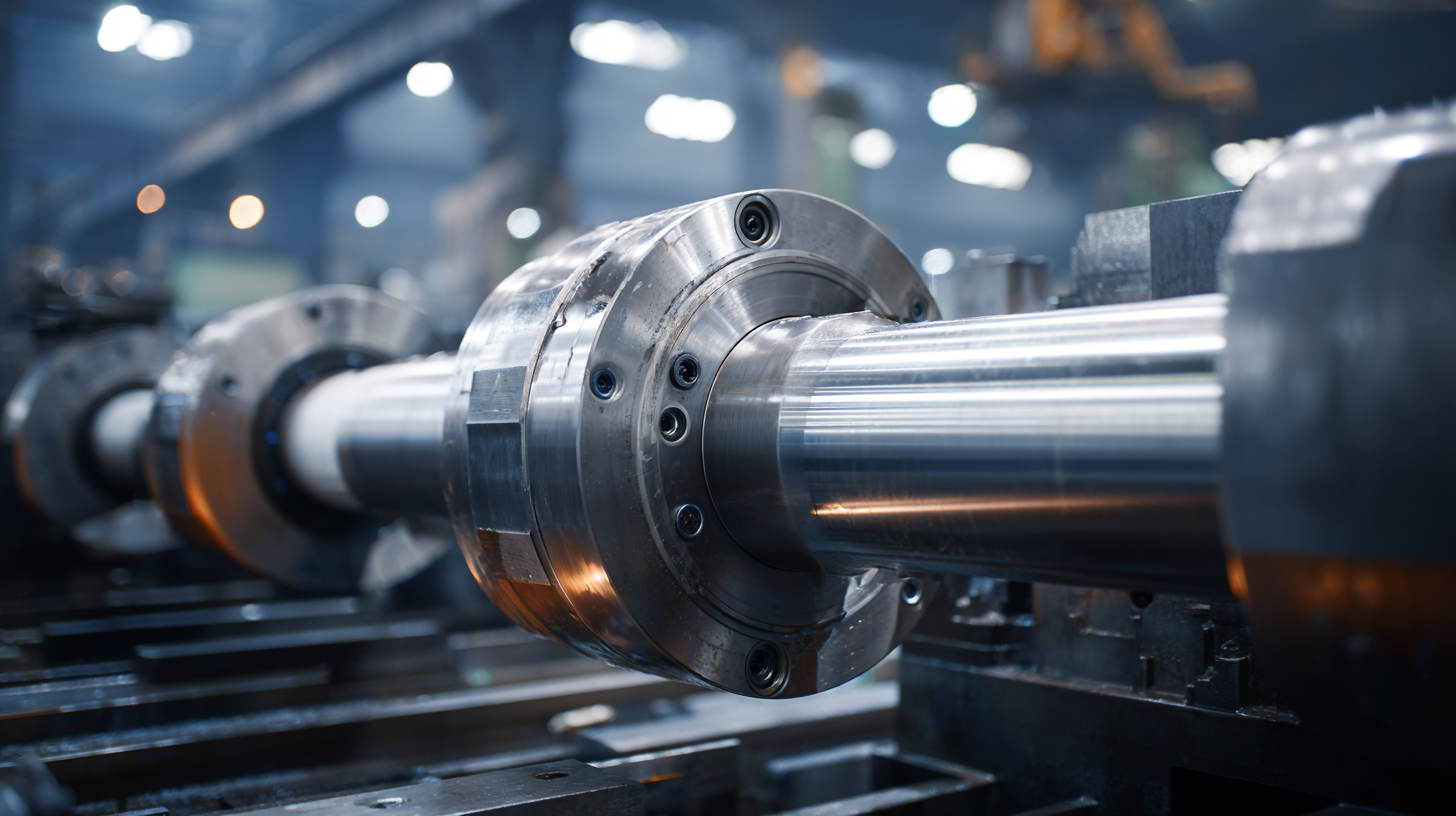

In the cold forging industry, technological innovations play a pivotal role in enhancing process efficiency and producing higher quality products. Recent studies indicate that integrating advanced automation tools can reduce cycle times by up to 30%, significantly increasing production output (Industry Reports, 2022). For instance, the adoption of robotic systems for material handling has not only streamlined operations but also minimized the risk of human error, thus improving overall product consistency and reducing scrap rates.

In the cold forging industry, technological innovations play a pivotal role in enhancing process efficiency and producing higher quality products. Recent studies indicate that integrating advanced automation tools can reduce cycle times by up to 30%, significantly increasing production output (Industry Reports, 2022). For instance, the adoption of robotic systems for material handling has not only streamlined operations but also minimized the risk of human error, thus improving overall product consistency and reducing scrap rates.

Moreover, the implementation of smart monitoring systems utilizing IoT technology allows manufacturers to gather real-time data on production processes. According to the Cold Forging Association, companies that employ these digital tools have reported a 15% improvement in operational efficiency, as they can promptly identify bottlenecks and perform predictive maintenance on machinery (CFA, 2023). These advancements enable a proactive approach to managing production and minimizing downtime, which is crucial in achieving maximum efficiency in cold forging operations. The industry's shift towards embracing digital transformation demonstrates a commitment to leveraging technology not only for enhanced output but also for sustainable manufacturing practices.