Leave Your Message

-

Phone

-

E-mail

In the modern manufacturing landscape, optimizing production efficiency is pivotal for gaining a competitive edge, particularly in sectors utilizing Brass Forging Parts. According to a report from the Global Brass Forging Market, the demand for brass components is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.6% from 2023 to 2030. This growth is driven by the increasing applications of brass in various industries, including automotive, aerospace, and electronics. By leveraging advanced forging techniques and employing data-driven strategies, manufacturers can enhance the performance and durability of Brass Forging Parts. Recent industry analyses suggest that adopting optimized manufacturing processes can lead to efficiency gains of up to 30%, significantly reducing waste and production time. Emphasizing the integration of digital tools and best practices is essential for ensuring that Brass Forging Parts meet the evolving demands of the market while maintaining cost-effectiveness and quality standards.

In the modern manufacturing landscape, optimizing production efficiency is pivotal for gaining a competitive edge, particularly in sectors utilizing Brass Forging Parts. According to a report from the Global Brass Forging Market, the demand for brass components is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.6% from 2023 to 2030. This growth is driven by the increasing applications of brass in various industries, including automotive, aerospace, and electronics. By leveraging advanced forging techniques and employing data-driven strategies, manufacturers can enhance the performance and durability of Brass Forging Parts. Recent industry analyses suggest that adopting optimized manufacturing processes can lead to efficiency gains of up to 30%, significantly reducing waste and production time. Emphasizing the integration of digital tools and best practices is essential for ensuring that Brass Forging Parts meet the evolving demands of the market while maintaining cost-effectiveness and quality standards.

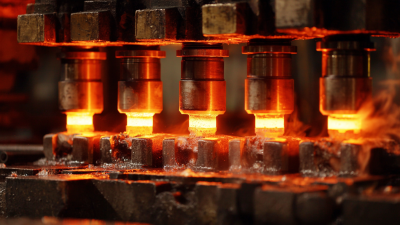

Brass forging plays a crucial role in enhancing manufacturing efficiency across various industries. The process of forging brass not only improves the mechanical properties of the material but also contributes to better accuracy and durability in the final products. This enhanced performance translates into reduced waste, fewer defects, and minimized production downtime, ultimately leading to a more streamlined manufacturing process.

Brass forging plays a crucial role in enhancing manufacturing efficiency across various industries. The process of forging brass not only improves the mechanical properties of the material but also contributes to better accuracy and durability in the final products. This enhanced performance translates into reduced waste, fewer defects, and minimized production downtime, ultimately leading to a more streamlined manufacturing process.

Tips for Optimizing Brass Forging:

By focusing on these aspects, manufacturers can harness the benefits of brass forging to achieve greater production efficiency and maintain a competitive edge in the market.

Brass forging parts have become increasingly vital in manufacturing industries due to their numerous advantages that contribute to optimizing production efficiency.

A report by the National Association of Manufacturers highlights that utilizing forged components can enhance the strength and reliability of products, as forgings typically exhibit superior tensile strength compared to castings or machined parts.

This inherent quality reduces the likelihood of product failure, thus minimizing downtime and associated costs during production.

Moreover, the use of brass forging parts in production processes can lead to significant cost savings. A study from the Forging Industry Association indicates that forging can reduce material waste by up to 30% when compared to traditional machining methods. This decrease in waste not only lowers raw material costs but also contributes to more sustainable manufacturing practices.

Additionally, brass alloys offer excellent corrosion resistance and thermal conductivity, making them particularly beneficial in applications such as plumbing and electrical components, where durability and performance are critical.

By integrating brass forging parts into their operations, manufacturers can achieve a leaner production process without compromising on quality or reliability.

In the manufacturing industry, optimizing production efficiency through brass forging parts is essential for achieving high output and reducing costs. One effective technique to improve brass forging procedures is the implementation of advanced heating methods. According to a 2022 industry report, utilizing induction heating can enhance temperature uniformity, resulting in a 15% reduction in energy consumption and improved material properties. By ensuring that brass reaches optimal forging temperatures more efficiently, manufacturers can not only streamline the process but also increase the lifespan of the equipment.

Another key technique for maximizing output is the integration of automation in the forging process. A study by the Brass Manufacturers Association reveals that companies adopting automated systems can boost production rates by up to 30%. Automation minimizes human error, accelerates workflow, and enables more precise control over forging parameters. Therefore, integrating robotics and smart technologies into brass forging operations can significantly enhance overall production efficiency.

Tips: To further optimize your forging processes, consider conducting regular maintenance checks on your machinery to prevent downtime. Additionally, investing in employee training can help workers better understand new technologies and improve overall operation efficiency. Lastly, analyzing production data systematically can identify bottlenecks and areas for continuous improvement.

| Technique | Description | Expected Output Increase (%) | Implementation Complexity |

|---|---|---|---|

| Die Design Optimization | Utilizing advanced CAD tools to improve die shapes and reduce production defects. | 15% | Moderate |

| Temperature Control | Maintaining optimal metal temperatures during forging to enhance malleability. | 20% | High |

| Automation of Processes | Implementing robotic systems to oversee repetitive tasks for increased precision and speed. | 30% | High |

| Quality Control Integration | Real-time monitoring of product quality metrics to swiftly address defects. | 10% | Moderate |

| Material Selection | Choosing higher-quality brass alloys to improve result consistency and durability. | 25% | Low |

Integrating advanced technologies into brass forging processes is pivotal for enhancing production efficiency in manufacturing industries. The adoption of automation and robotics in forging operations significantly reduces manual labor while increasing precision and speed. For instance, automated machines can handle complex tasks such as material feeding and product shaping, minimizing human error and ensuring consistent quality. Additionally, real-time monitoring systems powered by IoT enable manufacturers to track production metrics, allowing for immediate adjustments that optimize workflow and reduce downtime.

Furthermore, the integration of simulation software in the design phase of brass forging parts can streamline the production process. By using advanced modeling techniques, manufacturers can predict and analyze how materials will behave under different conditions, leading to more effective designs and fewer trials. This not only saves time and resources but also enhances overall output quality. In combination with techniques like 3D printing for creating molds, manufacturers can achieve a more agile and responsive production environment that meets the evolving demands of the market while maintaining cost efficiency.

Quality control measures play a crucial role in ensuring the effectiveness and reliability of brass forging parts in manufacturing industries. The recent announcement by the Ministry of Industry and Information Technology highlights the importance of maintaining high quality standards, particularly in the non-ferrous metals sector, to drive growth from 2025 to 2026. This reflects a broader recognition of quality as a pivotal factor influencing production efficiency and overall product performance.

To optimize production efficiency, manufacturers must implement stringent quality control protocols throughout the forging process. This includes regular inspection of raw materials, real-time monitoring during forging operations, and thorough testing of finished parts. By integrating advanced welding technologies, which serve as a vital bridge between material formation and product completion, companies can further enhance the structural integrity and longevity of brass components. Adopting these measures not only improves product quality but also contributes to the overall competitiveness of the manufacturing landscape.