Leave Your Message

-

Phone

-

E-mail

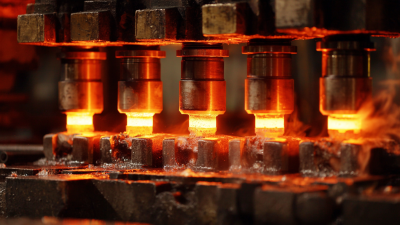

In the highly competitive manufacturing landscape, optimizing production processes for high-quality hot forging parts has become crucial for sustaining market relevance. According to a recent report by Grand View Research, the global hot forging market size is expected to reach USD 40.51 billion by 2025, growing at a CAGR of 6.3%. This accelerating growth underscores the necessity for manufacturers to enhance their production efficiency while maintaining product integrity.

The precision and durability of hot forging parts are paramount, as they are widely used in automotive, aerospace, and heavy machinery applications. By leveraging data-driven strategies and industry best practices, manufacturers can significantly improve their process workflows, ultimately leading to superior product quality and reduced operational costs. This blog will explore various optimization techniques tailored for the hot forging industry, ensuring that organizations can stay ahead in this evolving sector.

When it comes to producing high-quality hot forging parts, identifying key parameters is crucial for ensuring optimal results.

Temperature control is one of the most significant factors; maintaining the correct temperature not only enhances material ductility but also minimizes the risk of defects such as cracks and inconsistencies.

Thermal uniformity throughout the forging process must be closely monitored to ensure that the metal behaves predictably when subjected to stress.

When it comes to producing high-quality hot forging parts, identifying key parameters is crucial for ensuring optimal results.

Temperature control is one of the most significant factors; maintaining the correct temperature not only enhances material ductility but also minimizes the risk of defects such as cracks and inconsistencies.

Thermal uniformity throughout the forging process must be closely monitored to ensure that the metal behaves predictably when subjected to stress.

Another critical parameter is the forging speed. An optimal speed assists in maintaining the shape and quality of the part, while also reducing wear on equipment.

Slower speeds may allow for better control and precision, whereas faster speeds can improve productivity but at a potential cost to quality.

Additionally, tool design plays an essential role in influencing the flow of material during the forging process. Well-designed dies and tooling should accommodate the material's flow and reduce friction, which ultimately leads to more consistent final products.

Prioritizing these parameters can significantly improve the quality of hot forged parts and enhance overall production efficiency.

Implementing advanced technology in the forging process is essential for producing high-quality hot forging parts. One of the most impactful technologies is the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These tools allow for precise modeling of parts, ensuring that specifications are met before actual production begins. This significantly reduces the risk of errors and enhances the overall quality of the forged components.

Tip: Invest in training your workforce on the use of these advanced design and manufacturing technologies. Well-trained staff can leverage software tools more efficiently, leading to improved design accuracy and process optimization.

Another notable advancement is the integration of automation and robotics into the forging process. Automated systems can handle repetitive tasks with high precision, reducing human error and increasing production speed. This ensures that each forged part maintains uniformity and quality standards, which is crucial for applications in industries such as aerospace and automotive.

Tip: Consider implementing predictive maintenance for your equipment. By using sensors and IoT technology, you can monitor machine performance in real-time, addressing potential issues before they lead to costly downtime or production defects.

| Process Step | Technology Implemented | Benefits | Quality Metrics |

|---|---|---|---|

| Material Preparation | Advanced Material Scanning | Improved material consistency | Less than 2% defects |

| Heating | Induction Heating Systems | Faster heating cycles | Uniform temperature distribution |

| Forging | Computer Numerical Control (CNC) Machines | Enhanced precision | Tolerances within 0.01 mm |

| Cooling | Automated Cooling Systems | Controlled cooling rates | Reduction in warping |

| Quality Control | Automated Inspection Systems | Real-time quality checks | 99% pass rate on inspections |

Establishing robust quality control measures during the forging process is crucial for producing high-quality hot forging parts, especially in the context of increasing technological advancements and sustainability goals. The metal forging industry is experiencing rapid growth, driven by market demands for efficiency and environmental responsibility. According to industry reports, the global hot forging market is projected to reach USD 30 billion by 2027, indicating a significant push towards innovation and quality enhancement.

To ensure the highest quality in production, companies can adopt several best practices. First, implementing real-time monitoring systems can greatly enhance traceability and reduce defects. Data analytics tools allow manufacturers to track performance metrics throughout the forging process, ensuring that any deviations are promptly addressed. Additionally, incorporating sustainable materials and energy-efficient practices not only aligns with eco-friendly initiatives but also supports a company's commitment to quality.

Another tip is to invest in employee training focused on quality assurance techniques. A well-informed workforce can better identify potential issues and adhere to stringent quality standards, ultimately minimizing waste and maximizing output. By prioritizing quality control, manufacturers can not only meet but exceed the evolving expectations of their customers in an increasingly competitive market.

Training your team is a pivotal step in optimizing your hot forging production process. The efficiency and quality of hot forged parts largely depend on the skill level of your workforce. Implementing a structured training program can significantly enhance performance. Begin with a solid foundation by providing theoretical knowledge about hot forging principles, materials, and tools. This theoretical grounding prepares your team for real-world applications.

Incorporate hands-on training sessions where employees can practice techniques under supervision. Tips for these sessions include using simulation tools to mimic the forging process and rotating team members through different roles to broaden their skill sets. Encourage team discussions to address challenges and share solutions, fostering a collaborative environment where knowledge can be freely exchanged.

Evaluate your team’s progress through regular assessments and feedback sessions. This will ensure that they not only understand the techniques but also how to apply them effectively in various scenarios. By focusing on continuous improvement and investing in skill development, your team will become more adept at producing high-quality hot forging parts efficiently and consistently.

Optimizing material selection is crucial for enhancing the quality of hot forging parts. The choice of material directly influences the performance and durability of the final product. To achieve the best forging outcomes, it is essential to evaluate different materials and their mechanical properties. This approach not only ensures optimal strength and toughness but also contributes to cost-effectiveness in production.

Tips for material selection: Start by analyzing the specific requirements of the forging application, such as temperature resistance and load-bearing capacity. Consider utilizing advanced decision-making methods, such as Fuzzy Multi Criteria Decision Making (FMCDM), to compare material options based on various criteria. Furthermore, keeping up with current trends in tool steel development can provide insights into new materials that may offer improved performance.

In addition to material selection, it's vital to continuously monitor and assess the production process. Factors such as friction during deformation can significantly impact the quality of the forged parts. Implementing regular evaluations using techniques like the Rotary Compression Test can help identify optimal conditions for reducing friction, thereby enhancing the overall efficiency of manufacturing hot forging components.