Leave Your Message

-

Phone

-

E-mail

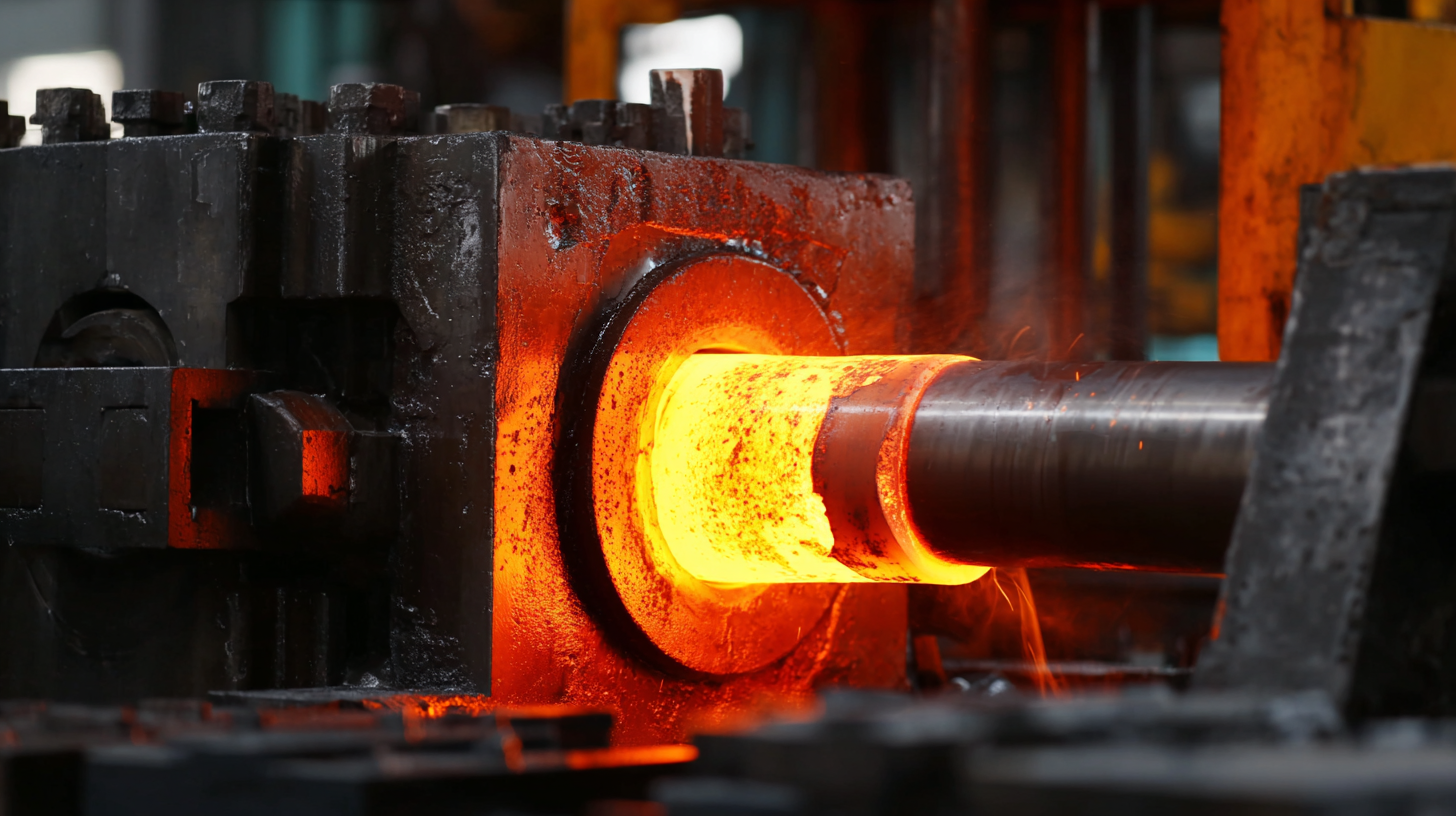

The selection of the right forging machine parts is critical for achieving optimal performance and durability in manufacturing processes. According to industry studies, improper selection can lead to a decrease in operational efficiency by up to 30%, significantly impacting production timelines and costs. As manufacturers seek to enhance productivity, understanding the specific requirements of forging machine parts becomes essential. Reports indicate that the global forging machinery market is projected to grow at a compound annual growth rate (CAGR) of 5.9% from 2021 to 2028, emphasizing the growing demand for high-quality machine components. Selecting the appropriate parts not only ensures a more reliable forging process but also extends equipment lifespan, thus offering a competitive edge in today's fast-paced manufacturing landscape. Therefore, it's imperative for industry professionals to make informed decisions based on material properties, compatibility, and performance metrics when choosing forging machine parts.

When selecting forging machine parts, it is crucial to understand the various types available in the market. Forging machines typically consist of components such as hammers, dies, and anvils, each serving a specific purpose in the forging process. Hammers, for instance, can be pneumatic or hydraulic and are essential for delivering the necessary impact force to shape the metal. The choice between these types depends on factors like the scale of production and the type of material being forged.

When selecting forging machine parts, several key factors must be considered to ensure optimal performance and durability. First, material selection is crucial. Parts made from high-quality steel or alloys can withstand the immense pressure and heat generated during the forging process, reducing wear and tear. It's essential to evaluate the specific requirements of the forging application, including the types of materials being processed and the expected operational conditions.

Another important aspect is the compatibility and precision of the parts. Each component should fit seamlessly with the existing machinery to prevent any misalignment that could lead to operational failures. Additionally, consider the manufacturer's reputation and the parts' adherence to industry standards, as these factors often correlate with reliability and longevity. Regular maintenance and the availability of replacement parts are also vital to sustaining performance over time. By focusing on these factors, manufacturers can choose the right forging machine parts, enhancing their production efficiency and minimizing downtime.

When selecting forging machine parts, the materials utilized play a crucial role in enhancing overall performance and longevity. According to the Forging Industry Association, the choice of materials can significantly affect not only the part's strength but also its wear resistance and ability to withstand extreme temperatures. For instance, high-strength steel alloys, commonly used in critical applications, can exhibit yield strengths exceeding 200,000 psi, which is essential for maintaining structural integrity under heavy loads.

Moreover, advancements in material science have introduced alternatives like titanium and advanced composites, which not only reduce weight but also improve fatigue resistance. A report by the American Society of Mechanical Engineers highlights that using titanium in forging applications can result in a weight reduction of up to 45%, while still providing superior performance characteristics. This is particularly beneficial in industries such as aerospace, where every ounce matters. By carefully evaluating these material options, manufacturers can ensure that their forging machine parts perform optimally and maintain durability over time.

When selecting forging machine parts, ensuring compatibility with existing equipment is crucial for optimal performance and durability. The integration of new parts into the current system can significantly impact the reliability and efficiency of the entire operation. Mismatched components may lead to increased wear and tear, unexpected downtimes, and a decline in product quality. Therefore, before making any purchasing decisions, it's essential to assess the specifications and requirements of both the new parts and the existing machinery.

Moreover, compatibility extends beyond mere physical dimensions. It encompasses the operational standards and technological capabilities of the parts involved. Understanding the working conditions—such as temperature ranges, load capacities, and material types—will guide the selection process and ensure seamless functionality. By prioritizing compatibility, manufacturers can not only enhance productivity but also prolong the lifespan of their machinery, ultimately resulting in cost savings and improved operational outcomes.

| Part Type | Material | Compatibility | Performance Rating | Durability Estimate |

|---|---|---|---|---|

| Anvil | Alloy Steel | High | 4.7/5 | 10 years |

| Die | Tool Steel | Moderate | 4.5/5 | 8 years |

| Hammer | Carbon Steel | High | 4.8/5 | 12 years |

| Ram | Aluminum Alloy | Low | 4.2/5 | 5 years |

| Support Beam | Structural Steel | High | 4.6/5 | 15 years |

Maintaining forging machine parts is crucial for ensuring optimal performance and longevity. According to the National Institute of Standards and Technology, regularly maintained machinery can experience up to 15% additional lifespan compared to neglected counterparts. To maximize the life of your forging machine parts, it is essential to implement a proactive maintenance strategy.

Tip 1: Develop a routine inspection schedule. Inspecting machine parts for signs of wear, such as cracks or uneven surfaces, allows for timely repairs before issues escalate, minimizing downtime and costs. It’s recommended to conduct these inspections at least bi-weekly, depending on usage frequency.

Tip 2: Ensure proper lubrication. Lubrication reduces friction, which is a significant factor in wear and tear. Research by the Society of Manufacturing Engineers indicates that consistent lubrication can extend the life of components by up to 30%. Use the manufacturer's specifications for lubricant types and schedules to maintain optimal performance.

By following these maintenance tips, operators can significantly enhance the durability and performance of their forging machine parts, ultimately leading to increased productivity and reduced operational costs.