Leave Your Message

-

Phone

-

E-mail

In the realm of manufacturing, the selection of the right Cold Forging Die is pivotal for achieving optimal production efficiency and product quality. Cold forging, a process that shapes metal at room temperature, relies heavily on precise dies to create intricate components with high accuracy and superior surface finishes. However, the plethora of options available can often overwhelm manufacturers, making the decision process daunting. Understanding the essential factors involved in choosing the right Cold Forging Die—such as material compatibility, design intricacies, and production volume requirements—can significantly influence manufacturing outcomes. In this blog, we will provide valuable tips and insights to guide you through the selection process, ensuring that your manufacturing needs are effectively met with the most suitable forging die.

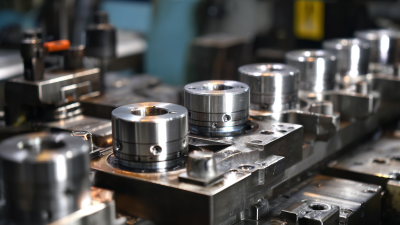

When selecting the right cold forging die for your manufacturing needs, several factors play a crucial role in ensuring maximum efficiency. One of the primary considerations is the material to be forged. Different materials require distinct die designs and tolerances. For example, softer metals may need less intricate dies, whereas harder materials could necessitate more robust and durable designs. Understanding the properties of the materials you work with will help refine your die selection.

Tip: Always consult with your die manufacturer regarding material compatibility. They can offer insights into the specific types of dies that work best with the materials you typically use.

Another vital factor is the complexity of the part being forged. More complex shapes often demand more elaborate dies, which can increase manufacturing time and costs. You should evaluate the balance between the complexity of the design and the production efficiency. Simplifying the part shape can lead to lower production costs and quicker turnaround times.

Tip: Consider investing in modular die systems, which allow for adjustments and modifications. This flexibility can help manage complexity without the need for entirely new dies for every design change.

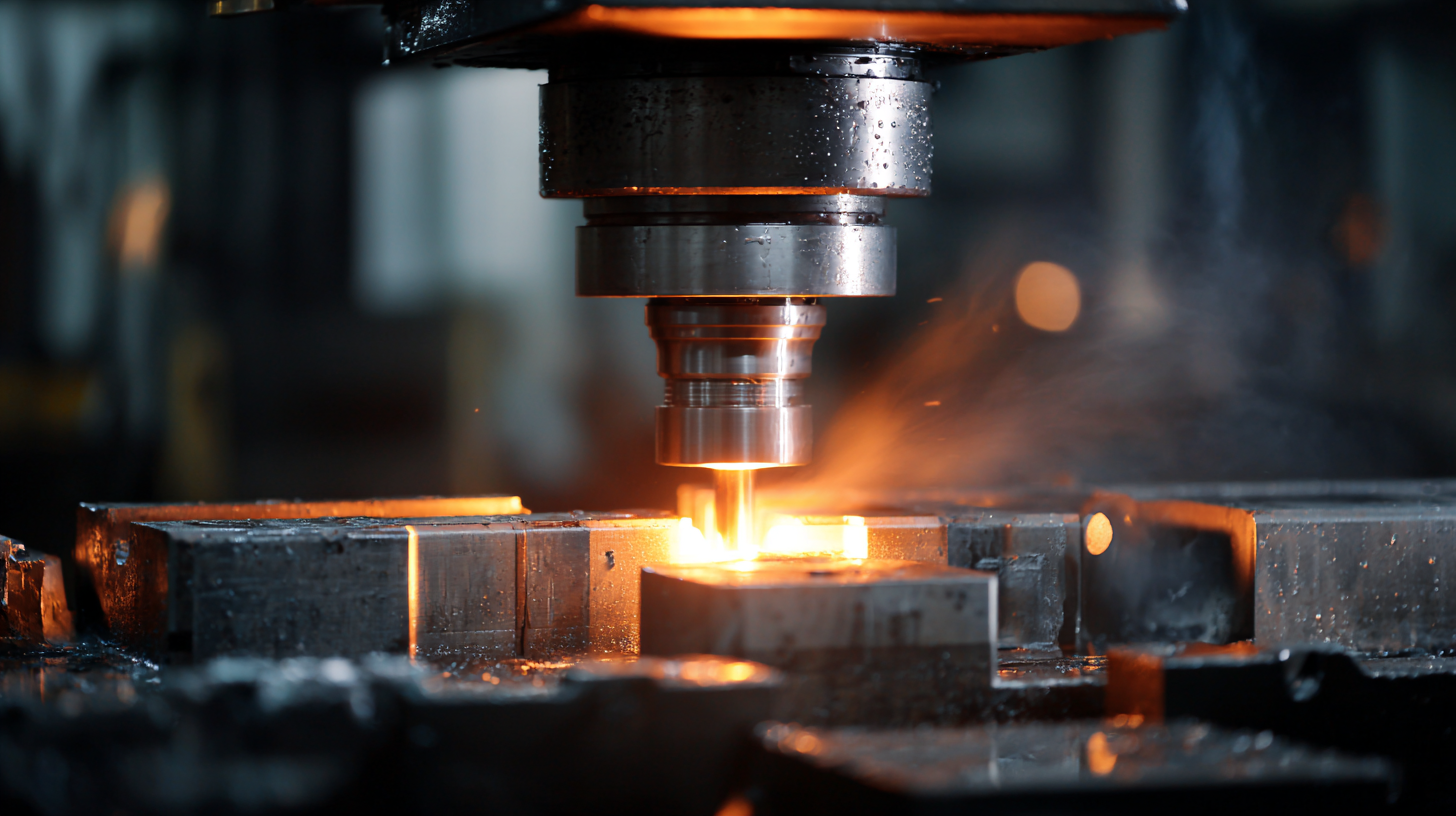

The selection of materials in cold forging die production is crucial for ensuring longevity and effective performance. According to a report by the International Journal of Advanced Manufacturing Technology, the right material can increase die life by as much as 50%, substantially reducing replacement costs and downtime. Common materials such as tool steel, alloy steel, and certain carbide composites offer distinctive benefits; for instance, alloy steels are often favored for their balance between toughness and wear resistance.

In addition, the manufacturing process itself can be influenced by material selection. A study conducted by the Materials Research Society highlights how specific die materials can impact the forging process, affecting parameters like temperature distribution and surface finish. For example, high-speed steels, known for their ability to maintain hardness at elevated temperatures, can enhance productivity in high-volume production settings. Therefore, understanding the properties and potential applications of various materials is essential for manufacturers aiming to optimize their cold forging processes and extend die lifespan.

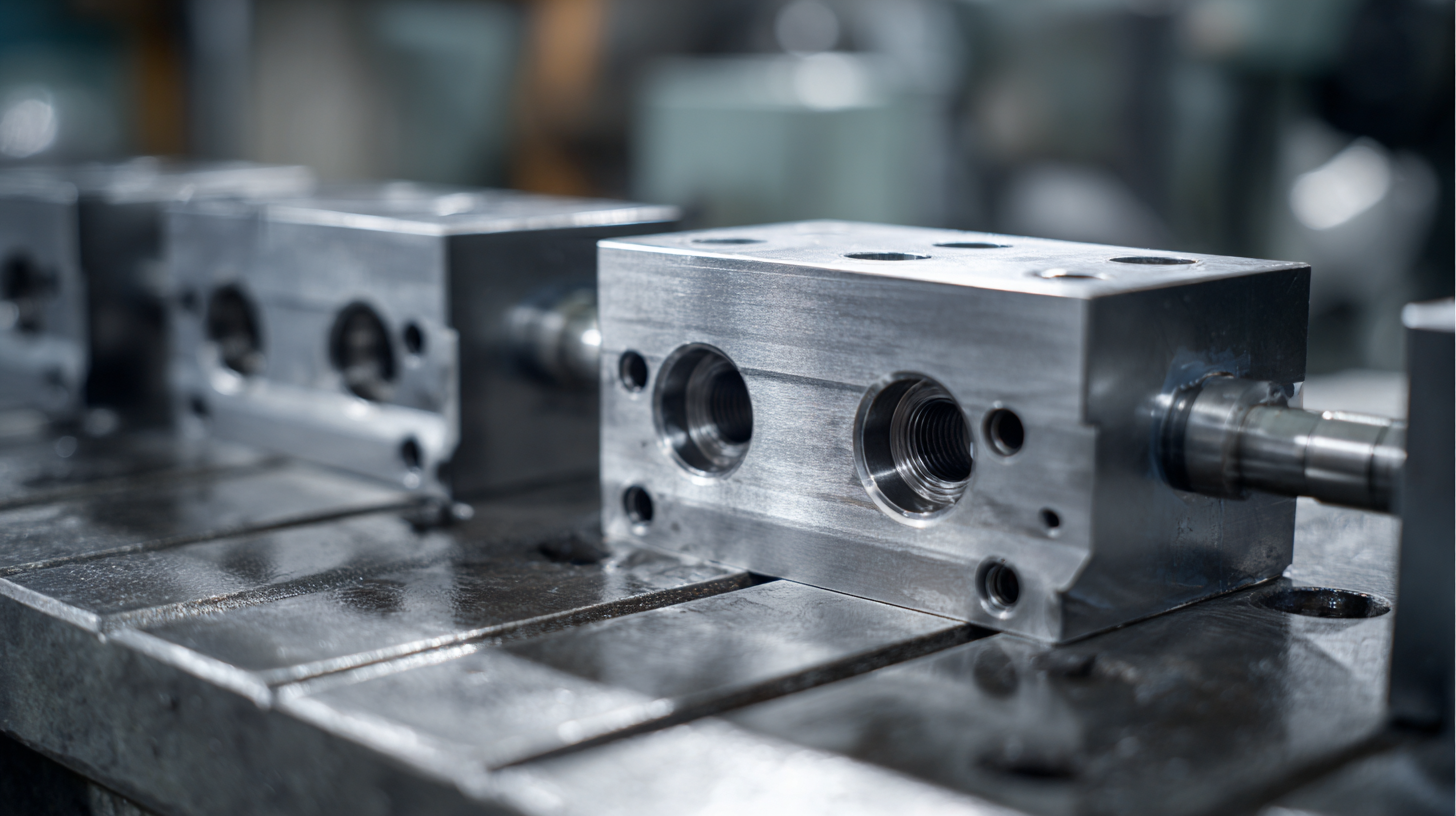

When selecting the right cold forging die for your manufacturing needs, understanding tolerances is crucial. Tolerances refer to the acceptable range of variation in a manufactured product's dimensions. In the cold forging process, precision is essential, as even minor deviations can lead to significant issues down the line. These issues not only affect product quality but can also result in increased waste and production costs. Thus, selecting a die that adheres closely to specified tolerances is imperative to maintain consistency and ensure reliability in your final products.

Moreover, the choice of die influences the overall efficiency of the cold forging process. High precision in the die design allows for smoother operations and minimizes the likelihood of defects during production. It is essential to assess the specific requirements of your project, such as material type and shape complexity, to determine the necessary tolerances. By aligning die selection with these tolerances, manufacturers can optimize the cold forging process, achieve superior quality, and ultimately drive greater customer satisfaction. Understanding the relationship between tolerances and precision not only enhances the manufacturing process but also fosters innovation in design and application.

When selecting the right cold forging die for manufacturing needs, evaluating cost-effectiveness is crucial. Quality and price must be balanced to ensure that the final product meets performance standards without straining the budget. The approach to die selection can be compared to economic evaluations in healthcare, where analyzing the cost and benefits of various options leads to better decision-making. Just as healthcare tools and interventions are assessed for their cost-effectiveness to improve patient care, manufacturers must scrutinize their die options to optimize productivity while maintaining high-quality outputs.

A thorough understanding of the total cost of ownership is essential in this context. This methodology goes beyond the initial purchasing price, taking into account long-term operational costs, maintenance, and potential savings from enhanced efficiency. Manufacturers should consider the performance and durability of the chosen die, as superior quality can lead to reduced defect rates and lower rework costs. By applying principles from economic evaluation, businesses can make informed decisions that align with their financial and operational objectives, ultimately leading to a successful manufacturing process.

In the rapidly evolving landscape of cold forging die technology, recent industry trends highlight significant innovations that are shaping its applications across various sectors. Notably, the aerospace cold forging market is anticipated to grow to USD 7.49 billion by 2032, with a compound annual growth rate (CAGR) of 3.20% between 2025 and 2034. This growth is largely driven by the increasing demand for lightweight materials, which are essential for enhancing fuel efficiency and performance in aviation.

Furthermore, countries like China are asserting themselves as front-runners in innovating advanced manufacturing techniques, including cold forging. The country's universities and domestic companies are pioneering methods that not only enhance the efficiency of die design and production but also significantly reduce production costs. As manufacturers globally seek to incorporate these advanced technologies, the focus on sustainable practices and improved resource management has emerged as critical drivers in the development of new cold forging dies, aligning with the broader trend of sustainability in manufacturing processes.