Leave Your Message

-

Phone

-

E-mail

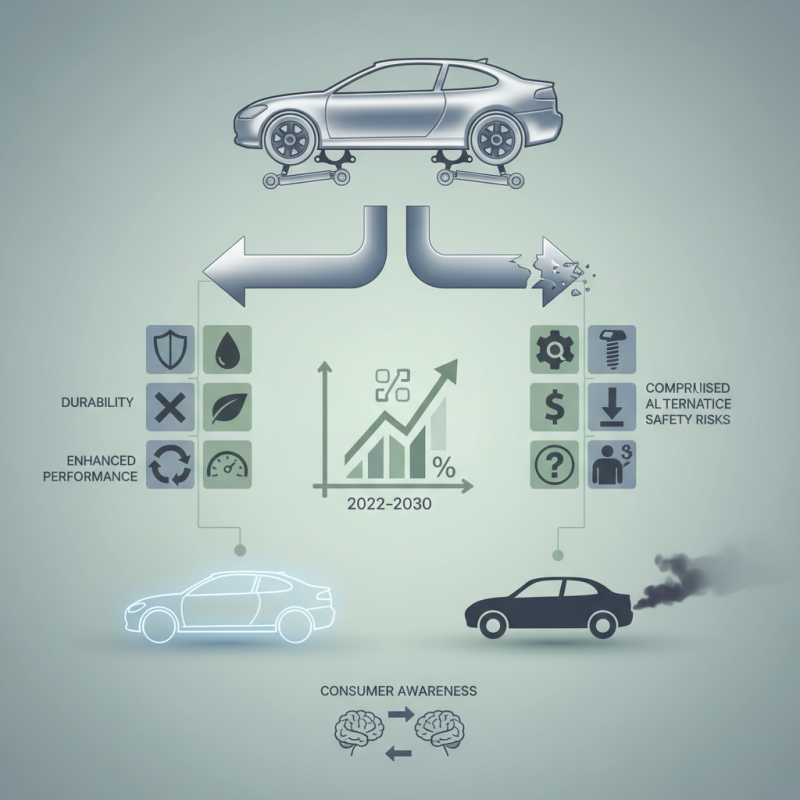

Stainless Steel Auto Parts are crucial in the automotive industry, providing durability and resistance to corrosion. According to a recent industry report by Market Research Future, the market for stainless steel automotive components is expected to grow at a compound annual growth rate (CAGR) of 7.5% from 2022 to 2030. This growth is driven by the increasing demand for lightweight and reliable automotive parts.

Expert John Smith, a leading figure in automotive materials, stated, "Stainless Steel Auto Parts enhance vehicle performance while ensuring longevity." His insights highlight the importance of selecting high-quality materials for automotive applications. However, not all manufacturers prioritize stainless steel. Some opt for cheaper alternatives, which can compromise vehicle quality and safety.

The shift towards sustainability also impacts the choice of materials. Stainless steel can be recycled without losing its properties, making it an eco-friendly option. Yet, awareness among consumers is still lacking. Manufacturers must embrace the advantages of Stainless Steel Auto Parts to meet evolving industry standards and consumer expectations while reflecting on their decisions and potential consequences.

Stainless steel auto parts are essential components in modern vehicles. They are made from an alloy that primarily contains iron, chromium, and nickel. This unique composition gives stainless steel its remarkable resistance to rust and corrosion. The addition of chromium, typically at least 10.5%, forms a protective layer that shields the metal underneath. Without this layer, parts would wear out rapidly.

These auto parts are crucial for various functions. For instance, they are often used in exhaust systems, fuel tanks, and structural components. The durability of stainless steel means that these parts can withstand harsh environments, including extreme temperatures and moisture. However, it's important to note that not all stainless steel grades are created equal. Some may not perform well under certain conditions, leading to potential failures.

Designing auto parts from stainless steel presents challenges. While the material is strong, it can be difficult to work with during fabrication. This sometimes results in pieces that are not perfectly shaped, requiring adjustments. Additionally, the cost of stainless steel can be higher than other materials. It raises questions about balancing cost and longevity. Understanding the trade-offs is key to using stainless steel effectively in the automotive industry.

Stainless steel auto parts play a crucial role in the automotive industry. They provide strength, durability, and corrosion resistance that are essential for vehicle performance. According to industry reports, over 60% of stainless steel used globally is applied in automotive production. This highlights its importance in creating reliable vehicles.

Advantages of using stainless steel in automotive applications are clear. One major benefit is its resistance to rust and corrosion. Vehicles are often exposed to harsh weather and road conditions. Stainless steel can withstand these challenges without compromising integrity. Furthermore, it requires less maintenance compared to traditional materials. This can reduce long-term costs for manufacturers and consumers.

Tips: Choose stainless steel parts for areas prone to moisture, such as exhaust systems. While stainless steel can be more expensive initially, its longevity makes it a smart investment. Keep in mind that not all stainless steel is the same; always check for quality grades. Watch for signs of wear even in stainless parts. Regular inspections can prevent surprises down the road.

Stainless steel auto parts are widely used due to their unique properties. They resist corrosion, making them ideal for vehicles exposed to various weather conditions. Additionally, their strength enhances vehicle durability. Common types of stainless steel auto parts include exhaust systems, fasteners, and brake components. Each of these plays a vital role in vehicle performance.

Exhaust systems made from stainless steel help reduce emissions effectively. They withstand high temperatures and prevent rust. Fasteners, often overlooked, secure parts together. They ensure safety on the road. Brake components, such as rotors and calipers, benefit from stainless steel’s strength. They provide reliable stopping power. However, the manufacturing process can sometimes result in imperfections.

It's essential to consider the environmental impact of production. Stainless steel parts can be recycled, but not all are. Awareness of this can lead to better practices in the industry. Maintenance is also crucial. Regular checks can spot early signs of wear. Understanding these factors can guide car owners in making informed decisions.

Stainless steel auto parts play a crucial role in vehicle performance. These parts enhance strength while reducing weight. A car's frame, exhaust system, or brake components made from stainless steel show improved durability. This is vital, especially for parts that endure harsh conditions. Corrosion resistance ensures longevity, preventing costly repairs.

The impact of stainless steel on vehicle performance is evident. A lighter vehicle accelerates faster and consumes less fuel. For instance, using stainless steel in exhaust systems can improve airflow. This efficiency boosts engine performance and enhances overall driving experience. However, the initial cost of stainless steel parts can be higher than alternatives.

Durability is not just about performance but also safety. Fragile parts can fail unexpectedly. This can lead to accidents or breakdowns. Even with stainless steel, improper installation might result in issues. Continuous maintenance is essential. It’s an ongoing commitment to keep vehicles operating at their best.

Stainless steel auto parts play a vital role in the automotive industry. They are highly durable and resistant to corrosion. This durability extends the lifespan of vehicle components, reducing the need for frequent replacements. According to a report by the International Stainless Steel Forum, up to 90% of stainless steel is recyclable. This feature promotes sustainability in auto manufacturing.

The environmental benefits of stainless steel cannot be overstated. Unlike other materials, stainless steel does not pollute during recycling. Moreover, it requires less energy to produce than new materials. A study indicated that using recycled stainless steel can reduce carbon emissions by up to 70%. This is significant for industries aiming to lower their environmental footprints.

However, challenges remain in optimizing recycling processes. Not all regions have efficient systems in place. Awareness about the recyclability of stainless steel is also lacking. Many consumers are unaware of the sustainable benefits this material provides. Improving education and infrastructure is crucial for maximizing the potential of stainless steel in the automotive sector.