Leave Your Message

-

Phone

-

E-mail

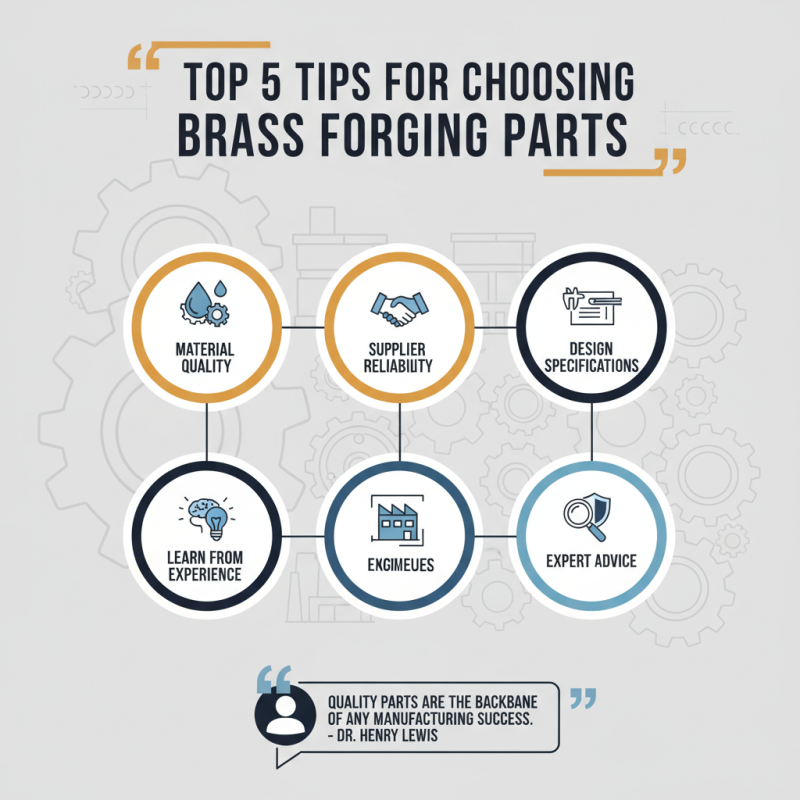

Choosing the right Brass Forging Parts is crucial for any production process. According to industry expert Dr. Henry Lewis, “Quality parts are the backbone of any manufacturing success.” His insights highlight the importance of selecting components that meet specific needs.

When evaluating Brass Forging Parts, consider factors like material quality, supplier reliability, and design specifications. Each aspect plays a critical role in product performance. Poor choices can lead to costly delays and failures. Often, companies overlook details, assuming all parts are equal. This assumption can be detrimental.

Reflecting on previous experiences can provide valuable lessons. Mistakes in part selection have occurred, revealing gaps in understanding. Therefore, a careful and informed approach is essential. Incorporating expert advice can vastly improve outcomes in your projects. As the demand for precision parts grows, ensuring the right choices becomes even more vital.

Brass forging parts play a crucial role in various industries. They are essential for applications that require durability and corrosion resistance. Common uses include plumbing fixtures, electrical connectors, and automotive components. Understanding their significance helps in selecting the right parts for your needs.

When choosing brass forging parts, consider material quality. Look for parts that meet your application standards. High-quality brass increases longevity. Additionally, assess the production method. Forged parts are typically stronger than cast ones. The forging process creates a tighter grain structure, which enhances overall performance.

Keep in mind, not all suppliers are equal. Research potential partners to ensure reliability. Look for experience in specific applications related to your needs. Communication is key. Engage with suppliers to ask about their processes and certifications. Don’t be afraid to voice concerns. A trustworthy partner will address your needs directly.

This chart illustrates the importance ratings of different factors when selecting brass forging parts. Factors such as durability and cost efficiency are rated highly, indicating their critical role in applications.

Choosing the right brass forging parts is crucial for various applications. Evaluating material properties plays a significant role in this. For instance, the tensile strength of brass can vary from 310 to 700 MPa, affecting its usability in different scenarios. A tensile strength above 400 MPa generally indicates it can withstand high-stress applications.

When selecting brass forging parts, consider corrosion resistance. According to industry studies, adding elements like nickel can enhance resistance. Look for specifications that indicate these additions. Furthermore, pay attention to the alloy composition. Different brass alloys, such as C36000 or C26000, have unique properties that can greatly influence performance.

Tip 1: Always request material certificates to confirm property claims. This simple step can prevent costly mistakes.

Another factor to assess is machinability. Brass is often chosen for its ease of machining. However, some alloys may pose challenges. Make sure your selected alloy aligns with your machining capabilities.

Tip 2: Engage with suppliers to gain insights about specific alloy performance. Communication can lead to informed choices that could save time and resources.

Ultimately, think critically about your requirements. Assessing material properties ensures you choose the best brass forging parts for your needs.

| Tip | Description | Material Properties | Recommended Applications |

|---|---|---|---|

| 1. Understand Material Composition | Choose brass with suitable alloying elements to match your application's requirements. | Copper content, Zinc ratio, Lead inclusion | Plumbing fittings, Electrical connectors |

| 2. Evaluate Strength Requirements | Assess the mechanical strength of the brass to ensure it can withstand operational stress. | Yield strength, Tensile strength | Structural components, Fasteners |

| 3. Consider Corrosion Resistance | Select brass with a coating or alloy composition that minimizes corrosion effects. | Corrosion resistance, Surface treatment options | Marine applications, Outdoor fittings |

| 4. Assess Machinability | Determine how easy the brass forging can be machined to meet fabrication needs. | Machining speed, Tool wear | Custom shapes, Precise fittings |

| 5. Verify Compatibility with Other Materials | Ensure that the selected brass parts are compatible with other materials used in assembly. | Thermal expansion, Electrical conductivity | Mixed-material assemblies, Electrical systems |

When selecting brass forging parts, it’s crucial to focus on manufacturing techniques. Quality can vary significantly based on methods used. Look for precision forging processes, as they enhance accuracy. This ensures parts will fit perfectly in their intended application.

One crucial tip is to evaluate the tools used in the forging process. Advanced machinery often leads to better outcomes. Check whether the manufacturer uses CNC machines. These tools minimize human error and improve consistency. Often, companies rely on older methods, which can lead to variability in production.

Another key point is to assess the staff's expertise. Skilled workers can adapt techniques for challenging designs. Their input can greatly affect the quality of the end product. However, not all manufacturers invest in training. This lack of skill can result in poorly made parts, which can compromise your project. Always inquire about staff training programs and their experience with brass materials.

When selecting suppliers for brass forging components, reliability is key. A reported 70% of manufacturers found that quality issues arose from improper supplier vetting. Businesses must prioritize finding partners with a proven track record. Reviews and testimonials from previous customers are invaluable. They often reveal insights into the consistency of product quality and supplier reliability.

It’s essential to verify a supplier's certifications. Look for industry-specific certifications which ensure adherence to quality standards. According to industry analysts, suppliers with ISO certifications are 40% less likely to have quality-related issues. Additionally, consider their production capacity. A supplier with limited capacity may not meet larger order demands, leading to delays and quality variations.

Lastly, assess communication and responsiveness. Poor communication can lead to misunderstandings and mistakes. Regular follow-ups can be crucial. A survey found that 60% of buyers valued efficient communication as a top factor in their supplier choice. Be prepared to reflect on experiences with suppliers to find the right fit.

When selecting brass forging parts, cost-effectiveness and longevity are crucial. Brass components may seem expensive at first, but their durability justifies the investment. You want parts that withstand wear and tear.

Evaluate the price per unit against the expected lifespan. It’s worth paying slightly more for higher quality.

One tip is to assess the application of the brass parts. Heavy-duty applications require more robust components, while lighter uses can prioritize cost. Sometimes, the cheapest option may incur higher replacement costs over time. Always consider the environment where brass components will operate.

Heat, moisture, and other factors impact longevity.

Don’t overlook manufacturer specifications. Quality varies significantly among producers. Poorly made parts might lead to frequent failures. Requesting sample parts can help you judge durability before purchase.

Remember, the decision-making process should factor in both immediate costs and long-term savings. Balancing these aspects ensures you make a smart and effective choice.