Leave Your Message

-

Phone

-

E-mail

Choosing the right Forging Machine Parts can significantly impact production efficiency. Industry expert John Smith, a well-known specialist in forging technologies, once stated, “Selecting quality parts is essential for optimal machine performance.” His insights reflect the crucial nature of this decision.

When looking for Forging Machine Parts, several factors demand attention. Quality materials play a vital role in durability and effectiveness. It's not merely about cost; investing in reliable components often brings long-term savings. Specialized suppliers can offer tailored solutions, which are crucial in today's competitive market.

However, not all suppliers meet high standards. Poorly chosen parts can lead to machine failure, resulting in costly downtime. It is important to assess suppliers thoroughly. Look for customer reviews and verify their industry experience. Such criteria can guide you to the right decision, refining your choices in the forging industry. This process requires both careful consideration and a willingness to adapt as needed.

When selecting forging machine parts, quality cannot be overstated. High-quality parts ensure durability and performance. A recent industry report indicates that nearly 75% of equipment failures are linked to poor-quality components. This statistic is alarming and highlights the need for careful consideration in this area.

Quality in forging machine parts directly affects production efficiency. Manufacturers using subpar components report a 30% increase in downtime. This means lost revenue and missed deadlines. Investing in quality parts can prevent these issues. It's not just about the initial cost; it’s about long-term savings and reliability.

Many buyers overlook certifications and quality standards. It's essential to ensure that parts meet industry specifications. Ignoring this can lead to catastrophic failures. A well-structured quality assurance process can make a significant difference. However, achieving high standards requires continuous improvement. This is a challenge many companies face, but it's critical for success.

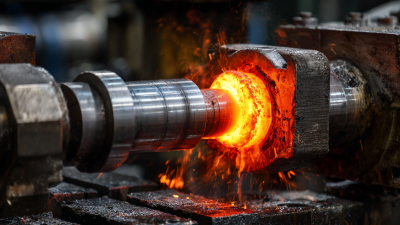

Choosing the right forging machine parts is crucial for optimal performance. Start by identifying the key specifications that affect your operations. Material quality plays a significant role. Choose parts made from durable, high-grade materials. They withstand the stress and heat of the forging process, ensuring longevity. Look at the size and dimensions. Accuracy in these specifications prevents fitting issues, which can lead to downtime.

Next, consider the compatibility of the parts. They should match the specifications of your forging machine. Different models have unique requirements that must be met. Sometimes, parts appear similar but may not fit properly. This oversight can result in costly repairs. Pay attention to the design and functionality as well. Parts that offer better performance may come at a higher price. Evaluate if the investment aligns with your production goals.

Lastly, reflect on your needs. What do you really require from these parts? Don't just go for the most expensive options. Think about the long-term benefits. Sometimes, a cheaper part may serve your purpose adequately. Carefully weigh the pros and cons. Making informed choices is essential for the overall efficiency of your operations.

| Specification | Importance | Recommended Value | Comments |

|---|---|---|---|

| Material Type | High | Carbon Steel, Alloy Steel | Choose based on mechanical properties required. |

| Temperature Resistance | Medium | Up to 800°C | Important for high-temperature applications. |

| Finish Type | Medium | Machined, Blasted | Affects final product performance and aesthetics. |

| Tolerance Level | High | ±0.01 mm | Precision is critical for fit and function. |

| Weight Capacity | High | Up to 10 tons | Ensure machinery can handle the load requirements. |

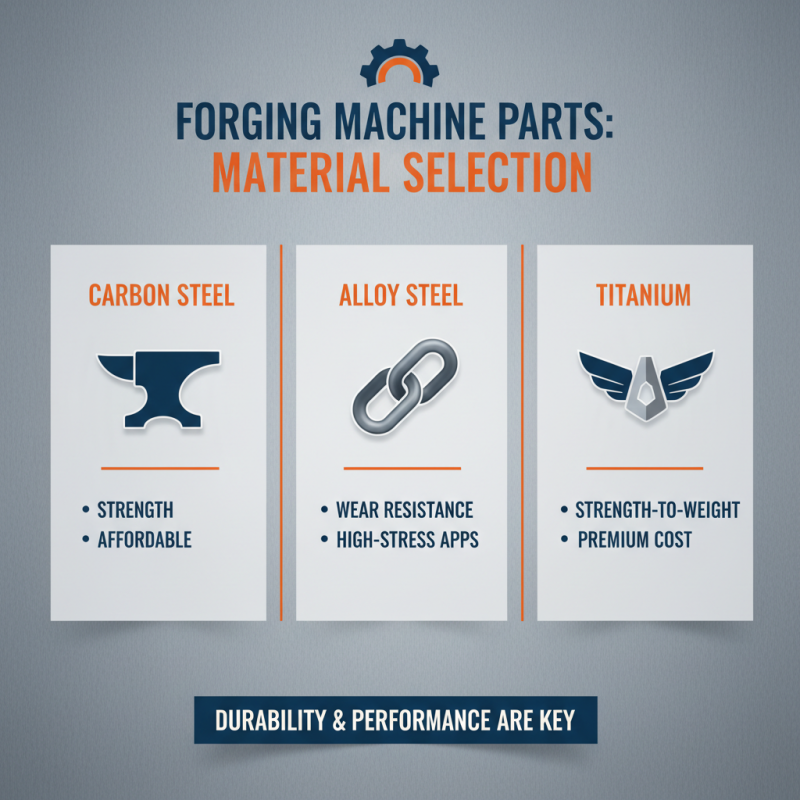

When selecting materials for forging machine parts, several factors are crucial. The type of material significantly influences the part's durability and performance. Common materials include carbon steel, alloy steel, and titanium. Carbon steel is popular due to its strength and affordability. Alloy steel offers better resistance to wear, which is vital in high-stress applications. Titanium, while expensive, provides excellent strength-to-weight ratios.

The American Society for Metals reports that nearly 80% of machinery failures are related to material issues. This statistic underscores the importance of thorough material assessments. Buyers need to consider thermal properties, tensile strength, and resistance to corrosion. For instance, parts exposed to extreme temperatures require specific alloys. In addition, improper material selection can lead to disastrous failures, affecting productivity and safety.

Testing is critical before final decisions. Industrial standards recommend conducting hardness and tensile tests. Engaging with suppliers who prioritize quality assurance is also beneficial. Yet, some manufacturers overlook these tests, leading to potential issues down the line. Inadequate understanding of material properties can result in costly mistakes, reducing overall efficiency. Therefore, investing time in material assessment is essential for achieving reliable and effective forging machine parts.

When choosing forging machine parts, the reputation of a supplier is essential. A strong reputation often indicates reliability. Look for reviews from other customers. A few negative comments don’t always reflect the entire picture, but consistent complaints should raise red flags.

Service quality is equally important. A good supplier responds quickly to inquiries. They should be willing to share their manufacturing processes. Ask about their quality control measures. It’s crucial to know how they ensure each part meets specifications. Reliable communication can prevent future misunderstandings.

Consider visiting the supplier’s facility. Seeing their operations in person provides valuable insights. Observing the workflow can highlight potential issues. Also, check how they handle customer service. If they show care and attention, that’s a positive sign. Neglect in this area can lead to problems down the line.

Budgeting effectively for high-quality forging machine parts is crucial. The costs can vary widely depending on materials and specifications. Setting a realistic budget will help avoid overspending. It’s essential to consider the cost of raw materials. Prices fluctuate, impacting your overall expense.

Sometimes, manufacturers offer deals that seem attractive. However, lower prices can compromise quality. It might be tempting to go for the cheapest option. This could lead to additional costs in the long run through repairs or replacements. Quality often correlates with price, so weigh your options carefully.

Do your research on suppliers and their reputations. Read customer reviews and check ratings. Engaging with peers can provide insights into their experiences. Negotiate pricing without compromising quality. Sometimes, investing a bit more upfront saves money later. Always reflect on your choices to ensure your budget aligns with your needs. Keep your long-term goals in mind when allocating funds.