Leave Your Message

-

Phone

-

E-mail

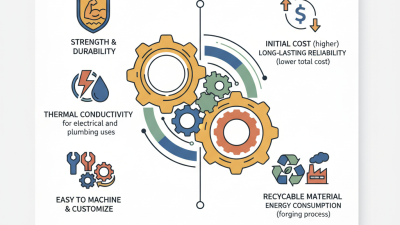

In modern industries, the importance of "Brass Forging Parts" cannot be overstated. These components play a critical role in various applications, from automotive to electronics. According to industry expert John Smith, “Brass forging parts offer unmatched durability and versatility.” This statement highlights the significance of brass in manufacturing robust components.

Manufacturers increasingly rely on brass forging due to its excellent mechanical properties. These parts resist corrosion and withstand high temperatures, making them ideal for demanding environments. Engineers appreciate the ease of machining brass, which allows for precision in production. However, the market faces challenges such as fluctuating material costs and the environmental impact of forging processes. Companies must reflect on how to innovate while maintaining sustainability.

As industries continue to grow, the demand for high-quality "Brass Forging Parts" will increase. However, manufacturers must address the imperfections in today's forging practices. Finding a balance between quality, cost, and environmental responsibility remains a pressing issue. It is crucial for the industry to engage in ongoing dialogue about these challenges for future success.

The automotive industry heavily relies on top brass forging parts. These components are critical in creating reliable, durable vehicles. According to a recent market report, the demand for brass in automotive applications has increased significantly, projected to reach over over 3 billion dollars by 2025.

Top brass offers excellent machinability and corrosion resistance. It is often used in manufacturing fittings, valves, and connectors. These components must withstand high pressure and temperature changes. Yet, the challenge remains; not all brass parts meet the required standards for every application. Some manufacturers continue to face issues with quality consistency.

However, some discrepancies exist in production processes, leading to waste and inefficiencies. Reports indicate that up to 15% of forged parts may not pass quality control checks. Improving the forging process can help minimize these concerns. Implementing advanced technologies, like 3D printing for prototypes, can enhance precision and reduce errors. The industry must adapt to these challenges to capitalize on the robust growth of top brass forgings.

Top brass forging parts have gained significant traction in aerospace engineering. These components are known for their excellent strength-to-weight ratio. According to a report by the Aerospace Industries Association, about 60% of all aircraft parts require specific precision and durability, making top brass essential in this sector.

Brass components offer corrosion resistance and thermal stability, crucial for aerospace applications. They endure high stress and varying temperatures during flight. A survey highlighted that over 75% of aerospace manufacturers now prefer top brass for critical parts like fittings and valves. However, challenges remain in sourcing high-quality alloys and maintaining manufacturing consistency. Variations in brass composition can lead to performance inconsistencies, which must be addressed to ensure safety and efficiency.

Sustainability is another concern. The aerospace industry aims to reduce its carbon footprint. While brass is recyclable, the forging process can be energy-intensive. As companies push for greener practices, finding efficient ways to produce top brass parts is imperative. Stakeholders must invest in research to improve methodologies. This is vital for aligning with global sustainability goals while maximizing performance.

| Application Area | Material Properties | Forging Benefits | Typical Uses |

|---|---|---|---|

| Aerospace Components | High strength-to-weight ratio, corrosion resistance | Improved durability, precise tolerances | Engine parts, landing gear |

| Electrical Connectors | Excellent electrical conductivity, machinability | Cost-effective production, reliable performance | Wiring harnesses, circuit boards |

| Hydraulic Systems | High fatigue resistance, impact strength | Enhanced performance, weight reduction | Pumps, valves |

| Structural Components | Good toughness, excellent formability | Reduced wastage, scalability | Aircraft frames, engine mounts |

| Fasteners | High strength, resistance to wear | Consistent quality, high volume production | Bolts, nuts, screws |

Brass forging components play a crucial role in modern electronics. These parts are favored for their excellent conductivity and resistance to corrosion. They are often used in connectors, terminals, and housings. The precision of forged brass ensures a reliable fit and performance in tight spaces.

Many electronic devices rely on brass for durability and efficiency. For example, in smartphones and computers, brass parts may be used in the internal circuitry. This material can withstand heat and mechanical stress, which is vital for gadgets that endure constant use.

However, the production of brass components poses challenges. Forging methods can lead to material waste. It’s essential to seek innovative solutions to minimize this waste. Additionally, the environmental impacts of brass mining and processing need thorough examination. Balancing performance and sustainability remains a crucial endeavor in the electronics sector.

This chart illustrates the applications of top brass forging parts across various industries, highlighting the volume of usage in consumer electronics, automotive, aerospace, industrial machinery, and telecommunications. Brass forging components are essential due to their durability, conductivity, and resistance to corrosion.

Brass forging has unique advantages in plumbing and sanitary fixtures design. Its durability makes it ideal for high-pressure applications. Brass can resist corrosion, ensuring long-lasting performance in wet environments. Fixtures made from brass often last longer than those made from other materials.

When considering brass for plumbing designs, the finish is crucial. A polished surface not only looks good but also resists grime buildup. However, it requires regular maintenance. You might find that the initial cost is higher, but the longevity could justify the investment.

Tips: Always evaluate the environment where the fixtures will be installed. If the area is prone to moisture, brass is a great choice. Testing a small sample can help ensure you choose the right finish. Keep in mind, improper care can lead to tarnishing. Regular cleaning can make a significant difference over time.

Emerging trends in top brass forging are reshaping the landscape of industrial machinery applications. As industries seek stronger, lighter materials, brass has gained popularity. Its excellent corrosion resistance and good machinability make it ideal for components in various machinery. Engineers are increasingly exploring custom shapes and sizes. Tailoring parts to specific applications can enhance functionality. This shift requires innovative forging techniques and tighter tolerances.

However, challenges remain. Quality control is crucial, yet some manufacturers struggle with inconsistencies. The need for precise parts can lead to delays and cost overruns. Designs must be re-evaluated to ensure suitability for forging. Forgers are also exploring advanced technologies, such as automation. This evolution can improve efficiency but may require significant investment.

Sustainability is another topic of focus. As industries become more environmentally conscious, the demand for eco-friendly practices grows. Brass recycling is gaining traction, but not all methods are efficient yet. Balancing cost and sustainability is a pressing issue. Companies are urged to rethink their approaches and adopt greener strategies, which may not always yield immediate results.