Leave Your Message

-

Phone

-

E-mail

As industries continue to evolve in the face of rapid technological advancements, the demand for high-performance materials is more pressing than ever. Among these materials, Forged Aluminum Parts have emerged as critical components in sectors such as aerospace, automotive, and industrial machinery, driven by their superior strength-to-weight ratio and enhanced durability. According to a market research report by MarketsandMarkets, the global aluminum forging market is projected to reach USD 7.31 billion by 2025, growing at a CAGR of 5.4% from 2020. This growth is fueled by the increasing adoption of innovative manufacturing processes and the need for lightweight, high-strength components.

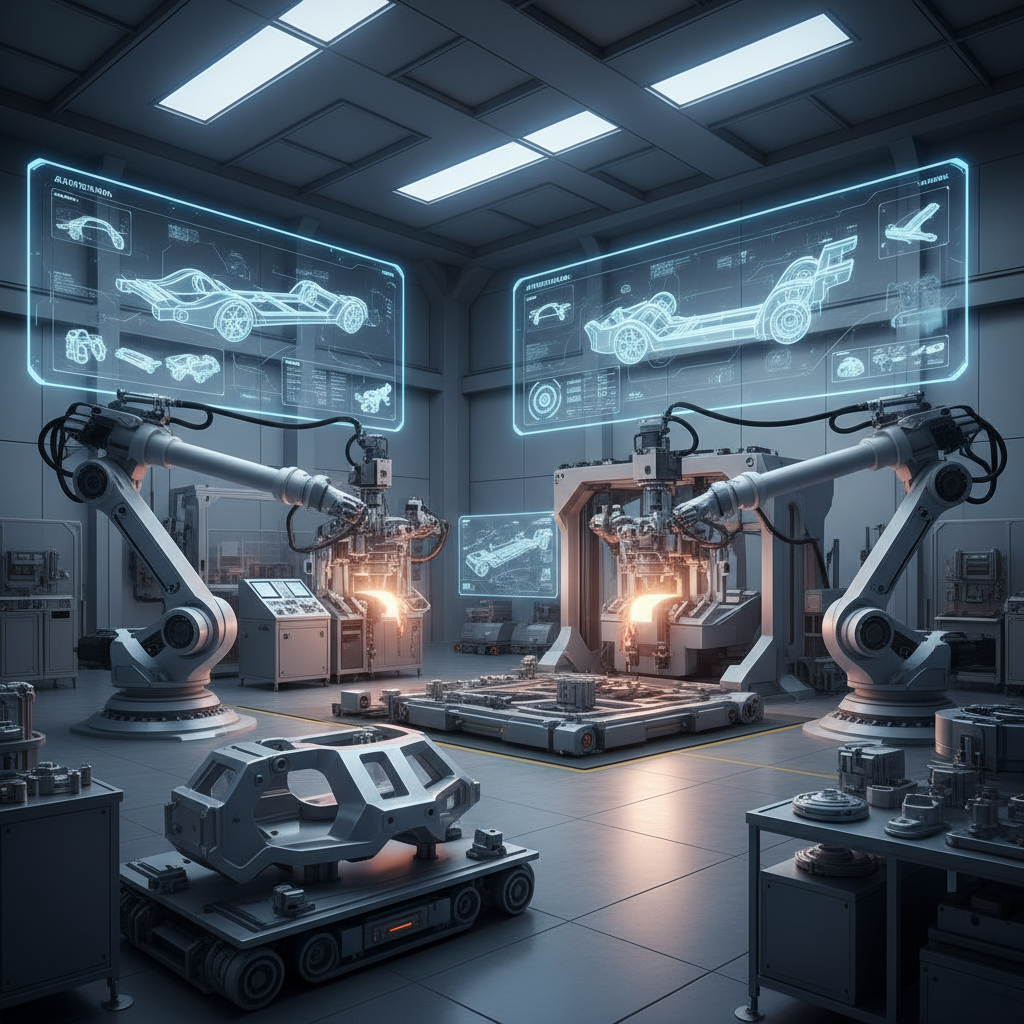

In recent years, innovations in forging techniques and technologies have paved the way for a remarkable transformation in the production and application of Forged Aluminum Parts. For instance, advancements in digital manufacturing and computer-aided design (CAD) tools enable manufacturers to create complex geometries that were previously unattainable. This not only enhances the performance of end products but also significantly reduces waste, contributing to more sustainable manufacturing practices. The integration of automation and robotics in forging processes further streamlines production, leading to improved efficiency and cost savings.

As we look ahead to 2025, it is crucial to recognize the role that these innovations will play in redefining sectors that rely heavily on Forged Aluminum Parts. With a focus on technological advancements, this article will highlight the top 10 innovations that are setting the stage for advanced applications, ultimately driving industry standards toward greater performance, reliability, and sustainability.

The manufacturing landscape for forged aluminum parts is evolving rapidly, with innovative techniques emerging to meet the demands of advanced applications in various industries. As we head into 2025, key advancements are focusing on enhancement in strength-to-weight ratios, which are critical for aerospace and automotive sectors. According to a recent report by Research and Markets, the forged aluminum market is projected to grow at a CAGR of 6.5%, driven by the increased demand for lightweight materials that improve fuel efficiency and reduce emissions.

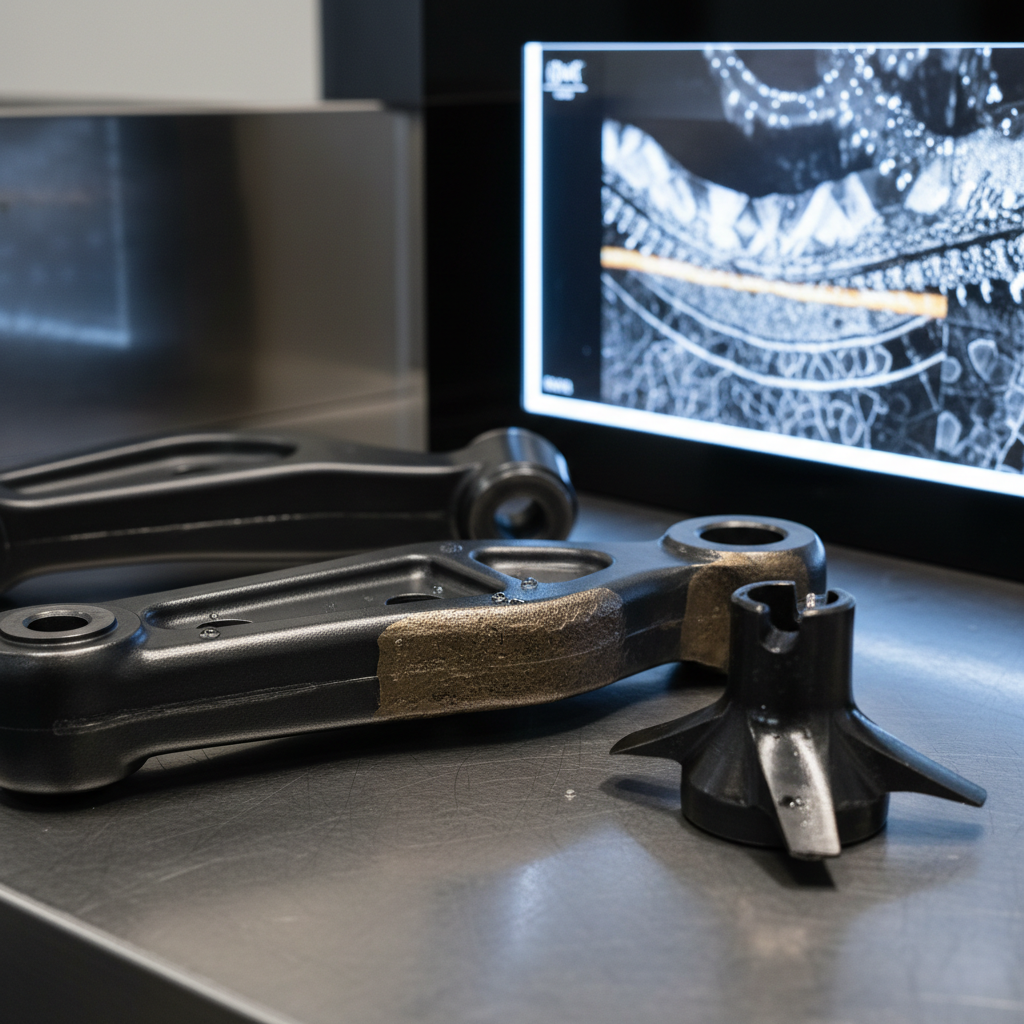

One notable trend is the integration of artificial intelligence in the forging process, enabling manufacturers to optimize operational efficiency and reduce waste. AI-driven predictive maintenance is also on the rise, allowing for real-time monitoring of equipment and minimizing downtime. Additionally, additive manufacturing techniques are being incorporated with traditional forging methods, resulting in hybrid processes that offer significant improvements in material properties and design flexibility.

**Tips:** When considering innovations in forged aluminum parts, manufacturers should evaluate the implementation of smart technologies to streamline production. Investing in staff training on advanced manufacturing processes can further ensure that teams are equipped to leverage these innovations effectively. Moreover, exploring partnerships with technology providers can facilitate access to cutting-edge tools that enhance product quality and manufacturing speed.

This chart illustrates the projected advancements in forged aluminum manufacturing techniques for 2025, highlighting key innovations and their expected impact on various applications.

The advancements in forged aluminum alloys are critical for enhancing the

strength-to-weight ratio, a key factor in various advanced applications,

particularly in the automotive and aerospace sectors. As industries push for greater efficiency and performance,

the North American aluminum market is projected to witness significant growth. According to recent industry analyses,

the market size could expand notably, driven by the demand for high-performance alloys that offer

superior mechanical properties. By 2033, the global market for aluminum crankshafts alone is estimated to reach

USD 7279.4 million, illustrating the rising need for reliable materials in automotive manufacturing.

Moreover, trends indicate a shift toward using innovative aluminum alloys that incorporate advanced elements,

such as scandium, which can greatly improve the mechanical strength of products

without significantly increasing weight. As reported, sales in various segments, including mobile phone alloys, are

expected to grow at a CAGR of 4.3%, hinting at the broader applicability and ongoing innovation

within the aluminum alloy market. The focus on sustainability and the development of new alloys positions the industry

well for future advancements, ensuring that forged aluminum parts remain integral to meeting modern application demands.

The advancements in surface treatments for forged aluminum parts are revolutionizing their performance and longevity in advanced applications. These treatments enhance the material properties of aluminum, making it more resistant to wear, corrosion, and fatigue. Techniques such as anodizing and hard coating not only improve surface hardness but also provide excellent bonding for lubricants, which is crucial in high-stress environments like automotive and aerospace applications. As a result, the durability of forged aluminum components is significantly increased, reducing the frequency of replacements and maintenance.

In the context of the automotive industry, the impact of these innovations cannot be overstated. High-performance piston systems, which are integral to engine efficiency, benefit immensely from the enhanced durability of aluminum parts. As engine builders seek to optimize performance, the integration of advanced surface treatments into casting processes ensures that components like connecting rods and pistons sustain their integrity under extreme conditions. Consequently, manufacturers are able to push the boundaries of what is possible in engine design, leading to more powerful, efficient, and reliable vehicles.

As the aluminum industry embraces digital transformation, the integration of automation and artificial intelligence (AI) is set to revolutionize forged aluminum production processes. China's significant investments in factory automation are already yielding results, providing a competitive advantage in sectors like automotive manufacturing. A recent report forecasts that the metal product market is expected to reach a valuation of USD 2,200 billion by 2035, indicating a robust growth trajectory driven by advanced technologies.

Innovations in AI are enabling companies to optimize manufacturing workflows, reduce costs, and enhance productivity. For instance, the collaboration between industry leaders aims to harness AI-driven smart manufacturing solutions, facilitating a shift towards greater efficiency and sustainability. Furthermore, the emergence of synthetic brains for industrial robotics, as exemplified by a significant funding round for a robotics company, illustrates the industry's commitment to advancing automation without the complexity of traditional coding. These developments reflect a broader trend in the aluminum sector, where innovative processes are critical for meeting the demands of a rapidly evolving market.

| Innovation | Description | Key Benefits | Application Areas |

|---|---|---|---|

| Advanced Alloy Composition | Utilization of new alloy compositions to enhance strength and reduce weight. | Improved performance in high-stress environments. | Aerospace, Automotive |

| 3D Forging Technology | Integrating 3D printing techniques with forged processes for complex designs. | Greater design flexibility and reduced material waste. | Medical Devices, Aerospace |

| AI-Driven Quality Control | Utilizing AI algorithms to monitor and control production quality in real-time. | Increased accuracy and reduced defect rates. | Manufacturing, Automotive |

| Smart Manufacturing Data Analytics | Leveraging big data to optimize production schedules and resource allocation. | Enhanced efficiency and cost savings. | All Industries |

| Sustainable Manufacturing Practices | Incorporating eco-friendly materials and processes in forging operations. | Reduction of carbon footprint and resource waste. | Construction, Automotive |

| Robotic Automation in Forging | Implementation of robotic systems for repetitive forging tasks. | Increased production speed and worker safety. | Manufacturing, Aerospace |

| Real-Time Monitoring Systems | Using IoT sensors to continuously monitor forging equipment health. | Predictive maintenance and reduced downtime. | Manufacturing, Industrial |

| Digital Twin Technology | Creating virtual replicas of physical forging processes for simulation. | Enhanced design validation and process optimization. | R&D, Manufacturing |

| Enhanced Surface Treatment Techniques | Innovative surface treatments for increased durability and corrosion resistance. | Extended component lifespan and performance. | Aerospace, Automotive |

The drive towards sustainability in the forged aluminum industry is increasingly prominent as companies prioritize environmentally friendly practices. A notable trend is the focus on recycling, with developing technologies allowing for the production of aluminum components from up to 95% recycled materials. According to recent industry analyses, the North America aluminum market is projected to expand significantly, driven by the growing demand for eco-friendly products. The market size for aluminum caps and closures alone is expected to reach approximately USD 14.60 billion by 2035, reflecting the shift towards sustainable packaging solutions.

Furthermore, innovative practices in manufacturing have led to the emergence of low-carbon aluminum casting methods, which utilize fully recycled scrap to minimize both energy consumption and environmental impact. Companies are increasingly adopting such practices to meet the dual challenge of meeting production needs while adhering to rigorous sustainability standards. As the global aluminum sector navigates a landscape marked by a shift towards green processes, companies are not only enhancing their carbon footprint but also setting the stage for a circular economy, which is essential for the future of advanced applications in the industry.