Leave Your Message

-

Phone

-

E-mail

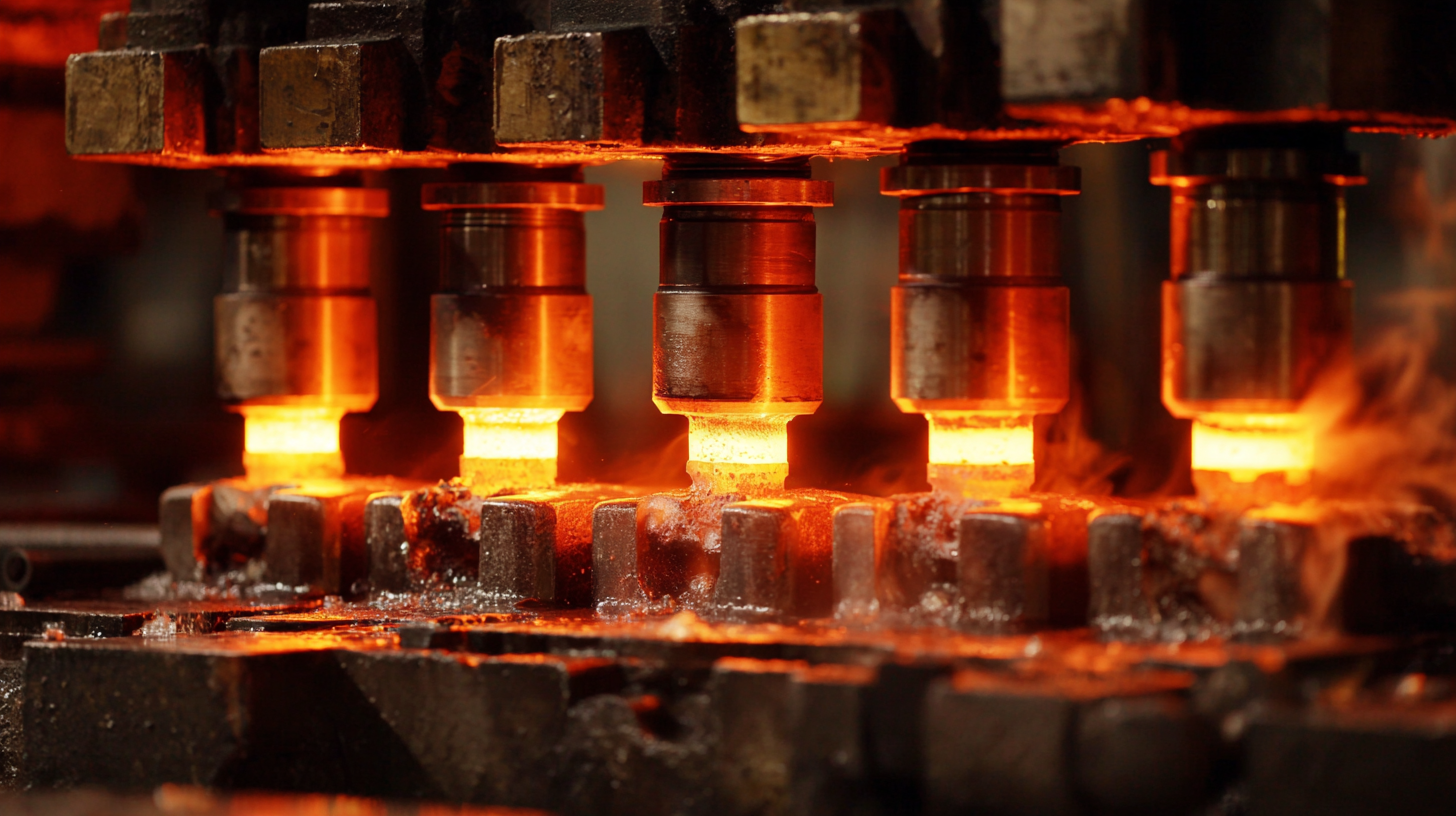

In today's global manufacturing landscape, sourcing high-quality brass forging parts is crucial for industries ranging from automotive to electronics. Brass forging parts, known for their excellent strength and corrosion resistance, play a vital role in ensuring product reliability and longevity. However, with numerous suppliers and varying quality standards across different regions, identifying the best sourcing strategies is essential to meet both performance and cost-effectiveness.

In this blog, we will explore detailed technical parameters that define superior brass forging parts, alongside practical "how to" tips for navigating the complexities of the global supply chain. By understanding these strategies, businesses can enhance their procurement process, ensuring they obtain the finest components tailored to their specific needs.

As the demand for brass forging parts continues to rise, emerging trends in sourcing are shaping the landscape for 2025. A recent report on the global forging market indicates that from 2025 to 2032, the sector is expected to witness significant growth, driven by an increasing emphasis on innovation and sustainability. Companies are now prioritizing partnerships with suppliers who can offer advanced manufacturing techniques and environmentally friendly practices.

Tip: Diversifying your sourcing strategy can help you tap into new markets and access high-quality materials. Consider working with suppliers in emerging economies, where cost-effective production and innovative forging technologies are on the rise.

Another notable trend is the growing importance of digital tools in the sourcing process. The adoption of smart technologies, such as AI and IoT, is facilitating better inventory management and enhanced communication with vendors. As the market evolves, suppliers who leverage these technologies will have a competitive edge.

Tip: Stay updated on technological advancements and invest in digital solutions that maximize efficiency. Embracing these changes can streamline operations and improve the overall quality of the brass forging parts you source.

Brass forging has become a vital component in various industries, from automotive to electronics, due to its strength and corrosion resistance. A comparative analysis of key global markets reveals significant trends shaping brass forging. For instance, Asia-Pacific is projected to dominate the brass forging market, accounting for over 40% of the total revenue by 2026, as reported by Market Research Future. This is largely driven by burgeoning manufacturing sectors in countries like China and India, where the demand for cost-effective and durable components continues to rise.

Tip: When sourcing brass forging parts, consider regions with established industrial infrastructures. Understanding local manufacturing capabilities and regulations can lead to better quality and lower overhead costs.

North America also plays a crucial role, with a significant focus on innovation and advanced forging technologies. According to Grand View Research, the U.S. brass forging market is expected to grow at a CAGR of 3.5% from 2021 to 2028, spurred by the demand for precision-engineered components. With many companies focusing on sustainability, sourcing from environmentally compliant suppliers can enhance your brand’s reputation while meeting regulatory standards.

Tip: Engage in regular supplier assessments to evaluate their production processes and environmental practices to ensure they align with your company’s sustainability goals.

When sourcing brass forging parts, eco-conscious buyers should prioritize sustainability by seeking out manufacturers that adopt green practices. One essential tip is to evaluate the sourcing of raw materials. Look for suppliers who utilize recycled brass or ethically sourced metals, as this can significantly reduce the carbon footprint associated with production. Additionally, inquire about the supplier's commitment to environmental certifications, which can provide assurance of their sustainable practices.

Another strategy is to assess the production processes employed by potential partners. Opt for manufacturers that use energy-efficient machinery and processes that minimize waste. Implementing lean manufacturing principles can also lead to more streamlined production, reducing unnecessary energy consumption and material waste. Additionally, consider suppliers who prioritize waste recycling and have programs in place to repurpose scraps generated during the forging process.

Finally, transparency in the supply chain is vital. Partner with suppliers who are open about their sourcing and production methods. By fostering relationships with companies that prioritize sustainability, you not only support eco-friendly practices but also ensure the quality and longevity of the brass forging parts you source.

In today’s fast-paced manufacturing landscape, technology plays a pivotal role in sourcing brass forging parts efficiently. By leveraging advanced software solutions, companies can streamline their procurement processes, improving both speed and accuracy. Tools such as artificial intelligence (AI) and machine learning algorithms help identify the best suppliers by analyzing market trends, pricing models, and quality ratings. This data-driven approach not only reduces the time spent searching for vendors but also enhances the overall decision-making process.

Furthermore, the use of digital platforms facilitates better communication between manufacturers and suppliers. Online marketplaces and sourcing platforms allow businesses to connect with verified suppliers worldwide, fostering transparency and trust. Additionally, technologies like blockchain can provide a secure way to track the entire supply chain, ensuring that each part meets the desired specifications and standards. By embracing these technological advancements, companies can avoid delays, minimize costs, and ultimately ensure they are sourcing the highest quality brass forging parts in the global market.

When sourcing brass forging parts globally, evaluating the quality control measures of suppliers is paramount. According to a study by the International Association of Engineering Industries, companies that implement rigorous quality control processes can reduce defects by up to 50%, significantly impacting overall operational efficiency. This is particularly critical in the brass forging industry, where precision and durability are non-negotiable for sectors such as automotive and aerospace.

Key quality control measures include the adoption of ISO 9001 standards, which have been shown to enhance customer satisfaction and operational performance. A report from the International Organization for Standardization highlights that organizations certified under ISO 9001 typically enjoy a 20% improvement in customer satisfaction rates. Additionally, implementing advanced testing methods, such as non-destructive testing (NDT) and material composition analysis, ensures the brass parts meet the required specifications and are free from flaws. By prioritizing these quality assessments, companies can secure reliable brass forging parts that align with industry standards and expectations, ultimately driving long-term success in their supply chain.

| Supplier Location | Quality Control Certification | Average Lead Time (Weeks) | Inspection Frequency | Customer Satisfaction Rating (1-5) |

|---|---|---|---|---|

| China | ISO 9001 | 8 | Every Batch | 4.5 |

| India | ISO 14001 | 10 | Every 2nd Batch | 4.2 |

| Germany | IATF 16949 | 6 | Every Batch | 4.8 |

| USA | AS9100 | 5 | Every Batch | 4.6 |

| Brazil | ISO 9001 | 12 | Every 3rd Batch | 4.0 |