Leave Your Message

-

Phone

-

E-mail

In the quest for improved production quality and efficiency, industries are increasingly turning to advanced forging machine parts as a pivotal solution. These components are designed to enhance operational precision and durability, leading to remarkable gains in productivity—up to 30% in some cases. By implementing state-of-the-art technology and innovative designs, businesses can optimize their manufacturing processes, reduce material waste, and elevate the performance standards of their products.

This guide will explore the transformative potential of forging machine parts, offering insights into how they can be effectively integrated into existing systems. Companies that invest in these advanced components not only streamline their operations but also position themselves competitively in a rapidly evolving marketplace.

As we delve deeper into the intricacies of forging machine parts, we will uncover best practices and strategies that will help you unlock unprecedented efficiencies in your production line.

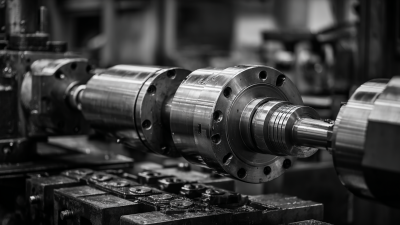

Advanced forging technology plays a crucial role in modern manufacturing by significantly enhancing production quality and efficiency. The precision and control offered by these technologies allow manufacturers to produce parts that meet increasingly stringent specifications. With the integration of computer numerical control (CNC) systems and robotics, advanced forging processes can achieve tighter tolerances and improved material properties, leading to superior products.

Moreover, the ability to automate various aspects of the forging process reduces human error and increases production speed. This efficiency translates to a reduction in waste and rework, directly contributing to cost savings. As industries continue to demand higher performance and reliability from their products, embracing advanced forging technology becomes essential for manufacturers aiming to stay competitive in the market. With the potential to enhance production quality by up to 30%, the adoption of these innovative techniques is not just beneficial but imperative for success in modern manufacturing.

| Dimension | Before Advanced Forging | After Advanced Forging | Improvement (%) |

|---|---|---|---|

| Production Speed (Units/hour) | 80 | 104 | 30 |

| Material Waste (%) | 15 | 10 | 33.33 |

| Defect Rate (%) | 5 | 3.5 | 30 |

| Energy Consumption (kWh) | 1000 | 850 | 15 |

| Overall Equipment Effectiveness (%) | 75 | 90 | 20 |

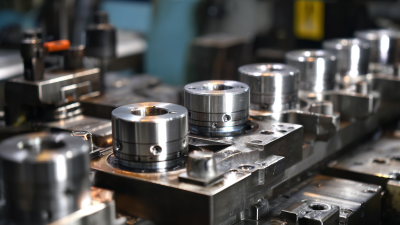

Advanced forging machine parts are revolutionizing production efficiency, contributing to a remarkable 30% enhancement in production quality. Key features of high-quality forging machine parts include precision, durability, and superior material properties, all of which are crucial for achieving optimal performance in manufacturing processes. The integration of predictive maintenance strategies is also significant in this context. As outlined in recent industry reports, predictive maintenance relies on collecting equipment operational data, enabling manufacturers to identify potential failures and performance declines proactively.

Moreover, advancements in machine learning are proving invaluable in quality control for manufacturing processes, including metal additive manufacturing. A recent review published in Advanced Powder Materials emphasizes how machine learning can automate quality assessments, significantly improving product output consistency and reducing waste. Reports indicate that the semiconductor equipment components market is also witnessing growth, projected to reach $6.8 billion by 2030, with applications in precision and reliability further driving demand for high-quality machine parts. These advancements highlight not only the importance of technology but also the evolving landscape of equipment manufacturing, where quality and innovation are paramount.

The implementation of advanced forging machine parts has proven to be a game-changer in manufacturing, particularly in terms of enhancing production quality. By integrating precision-engineered components, manufacturers can achieve a significant uplift in their operational efficiency. This enhancement not only streamlines processes but also minimizes the likelihood of defects, leading to a more consistent product output. As a result, businesses can produce high-quality products at a faster rate, yielding a remarkable 30% increase in quality metrics.

Quantitative benefits of enhanced production quality are evident across various metrics. For instance, reduced waste and downtime translate into lower operational costs, while higher quality standards often lead to increased customer satisfaction and loyalty. Subsequent benefits include improved market competitiveness and a stronger brand reputation. With such advancements in forging technology, companies are empowered to meet growing demand without compromising quality, ultimately laying the foundation for sustainable growth in a highly competitive landscape.

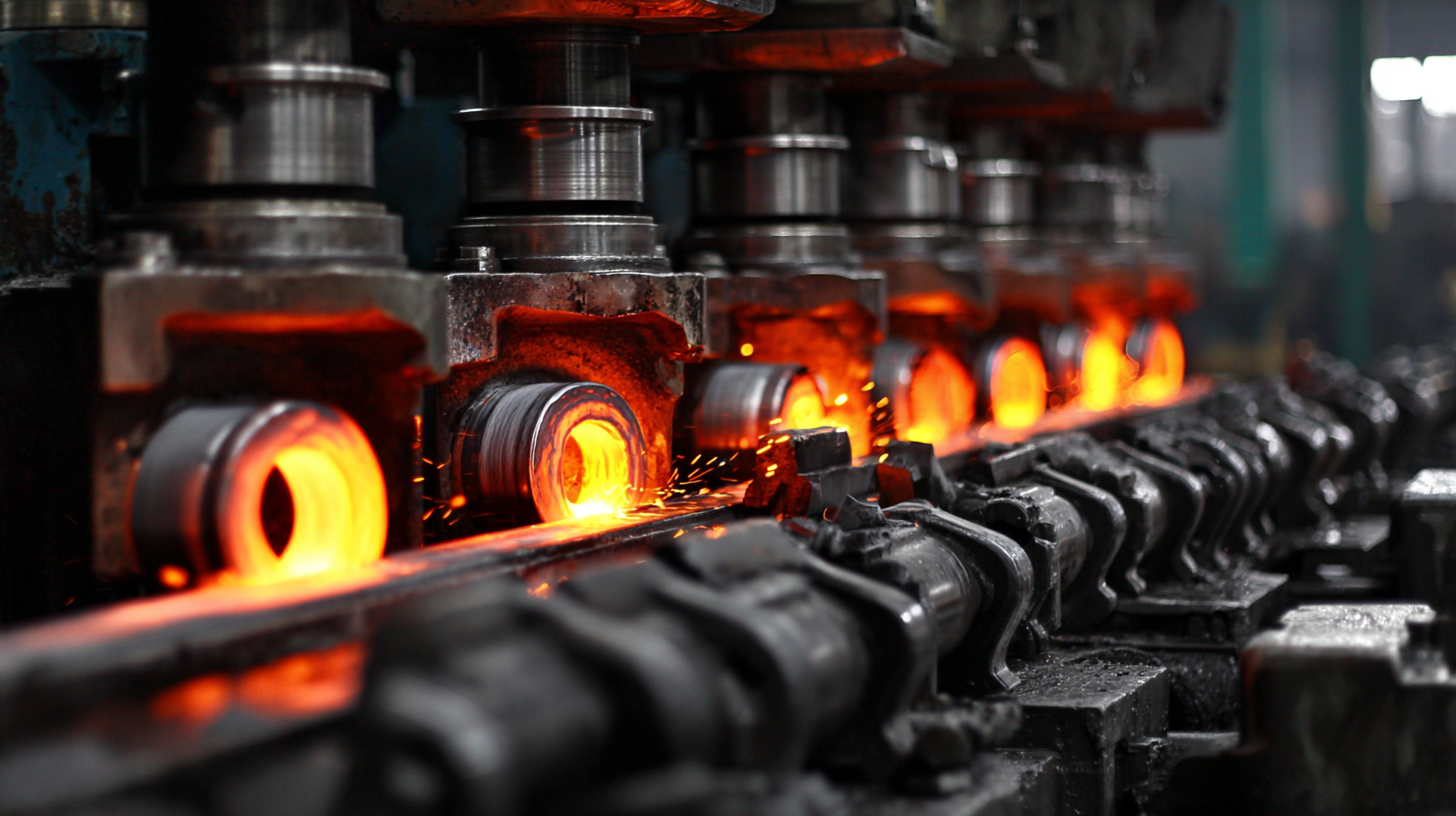

In the world of manufacturing, the choice between traditional and advanced forging techniques can significantly impact production quality and efficiency. Traditional forging methods often rely on manual processes and basic machinery, which can lead to inconsistencies and longer production times. While these age-old practices have their merits, such as lower initial costs and a familiar operational framework, they often struggle to meet the demands of modern industry, especially in terms of precision and scalability.

On the other hand, advanced forging techniques leverage cutting-edge technology, such as automated machinery and computer-controlled processes, to enhance production quality by 30%. These innovations not only reduce human error but also optimize material usage and energy consumption. For instance, sophisticated forging machines can adjust parameters in real-time, ensuring that each piece meets stringent quality standards. By conducting a comparative analysis of both methods, it becomes evident that investing in advanced machinery yields substantial long-term benefits, including improved product durability and reduced waste, ultimately leading to a more efficient manufacturing landscape.

This chart illustrates the comparative analysis of production quality achieved through traditional versus advanced forging techniques. Advanced forging enhances production quality by up to 30%, reaching a quality standard of 100% compared to 70% for traditional methods.

The forging industry is witnessing a transformative shift with the advent of advanced machinery, aimed at boosting production efficiency. According to a recent report by MarketsandMarkets, the global forging machinery market is projected to reach $5.2 billion by 2026, growing at a compound annual growth rate (CAGR) of 4.4%. This growth is driven by the need for high-quality, cost-effective production methods, as industries increasingly seek to enhance their operational capabilities. Advanced forging machines utilize automation and data analytics to streamline processes, significantly reducing downtime and waste.

Future trends in forging machinery are increasingly focused on integrating smart technologies such as IoT and artificial intelligence. A study by Technavio indicates that the use of AI in manufacturing could improve operational efficiency by up to 30%. These technologies enable real-time monitoring and predictive maintenance, facilitating a proactive approach to production. Additionally, advancements in materials science are allowing for the creation of more durable forging machine parts, enhancing performance and longevity. As the industry evolves, these innovations promise to redefine production standards, ensuring manufacturers remain competitive in an increasingly dynamic market.