Leave Your Message

-

Phone

-

E-mail

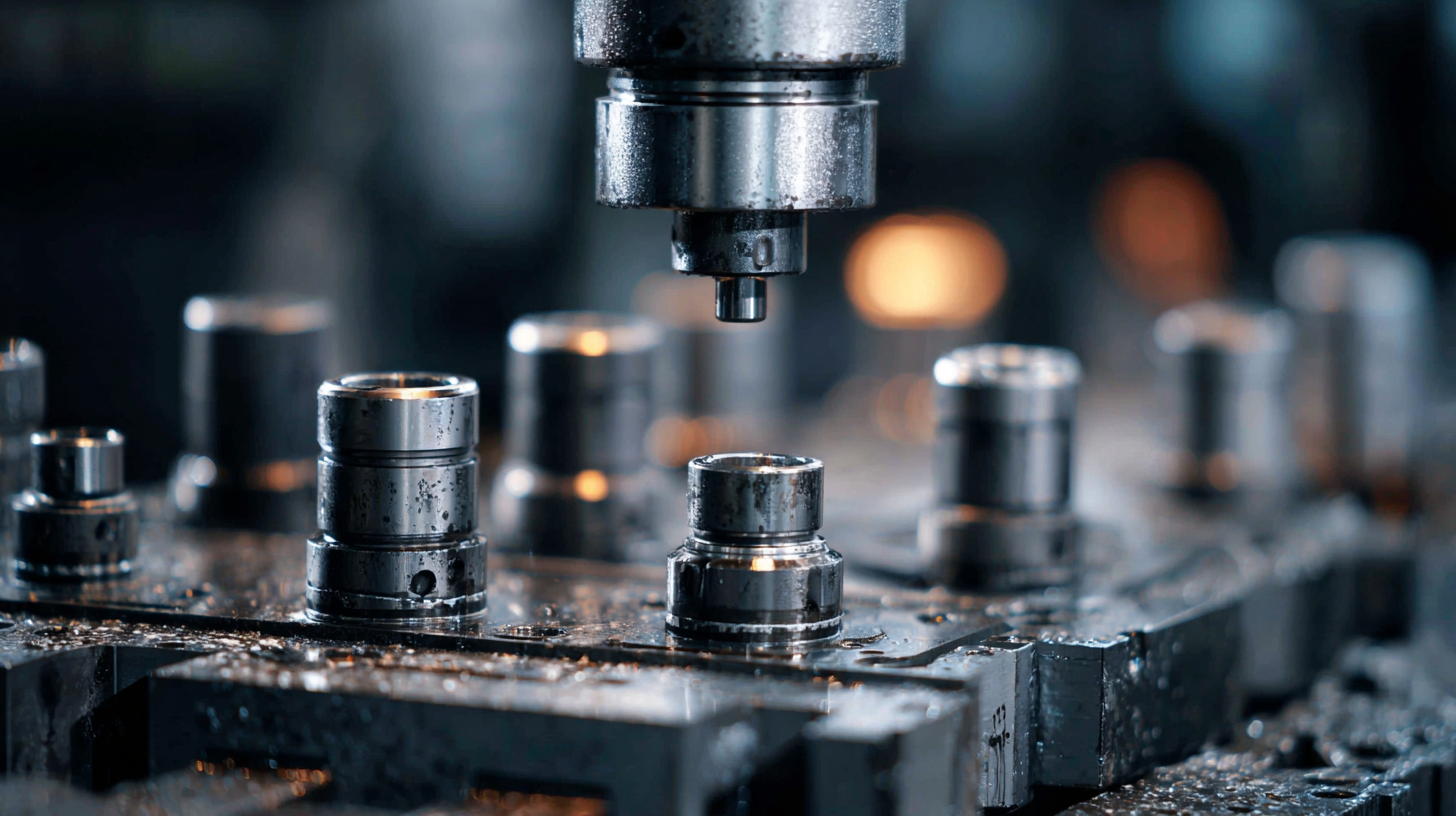

In the ever-evolving landscape of modern manufacturing, achieving efficiency without compromising quality is paramount. One of the pivotal components that significantly contributes to this goal is the Cold Heading Die. Renowned for their precision and durability, Cold Heading Dies have become a cornerstone in the production of various fasteners and metal components. As manufacturers worldwide seek to optimize their processes, the unmatched benefits of utilizing top-tier Cold Heading Dies made in trusted manufacturing hubs, such as China, cannot be overstated. Not only do these dies enhance productivity by ensuring consistent output, but they also embody a commitment to quality that has earned global trust. In this blog, we will explore how investing in the best Cold Heading Die can unlock greater efficiency and reliability in manufacturing processes, ultimately driving innovation and profitability in the industry.

In the realm of modern manufacturing, the precision of tools and processes significantly dictates the quality of the end products. Enhanced precision in cold heading dies is one of the key elements that can drastically improve efficiency and output in production lines. Cold heading dies allow manufacturers to create complex shapes from metal without the need for extensive machining, minimizing waste and reducing production time. The accuracy of these dies ensures that every component produced meets stringent specifications, leading to lower defect rates and increased reliability.

Moreover, the integration of advanced technologies in the design and production of cold heading dies has paved the way for enhanced customization capabilities. This means manufacturers can produce tailored components that fit specific customer needs without compromising on precision. The precise shaping of materials also results in more durable products, which can withstand rigorous applications. As industries continue to demand higher standards, investing in quality cold heading dies will be crucial for companies looking to maintain a competitive edge while optimizing their manufacturing processes.

In modern manufacturing, the push for increased production speed is more critical than ever, making advanced die technology an invaluable asset. The implementation of best cold heading dies has proven to significantly enhance efficiency. According to a report by MarketsandMarkets, the global cold heading market is expected to reach USD 3.1 billion by 2025, driven largely by the need for faster production times and higher precision in parts manufacturing. Cold heading dies are designed to handle complex shapes and forms with unparalleled accuracy, which reduces the cycle time and increases output.

Additionally, advanced die technology contributes to material savings and scrap reduction, key factors in optimizing manufacturing processes. A study by the National Association of Manufacturers found that companies utilizing improved die designs reported a 30% increase in production speed while reducing waste by as much as 25%. This efficiency not only results in cost savings but also enhances competitiveness in a rapidly evolving market. As manufacturers continuously seek avenues for optimization, embracing state-of-the-art cold heading technology remains a strategic move to unlock new levels of productivity.

In the landscape of modern manufacturing, particularly in food production, the adoption of best practices such as cold heading dies has emerged as a game changer for enhancing cost efficiency. The integration of cold heading dies significantly minimizes material waste, which is a critical concern in an industry facing increasing pressure from climate change and supply chain vulnerabilities. Reports indicate that manufacturers employing advanced cold heading technologies can reduce waste by up to 30%, translating into substantial savings and improved profit margins.

A pivotal strategy for optimizing operations in food manufacturing is the Lean Six Sigma approach. This methodology focuses on eliminating waste and enhancing process efficiency. By incorporating cold heading dies into their processes, manufacturers can streamline production, effectively minimize defects, and ensure consistent quality. In fact, businesses that utilize such technologies alongside Lean Six Sigma practices report increases in operational efficiency by as much as 25%, underscoring the potential benefits of integrating innovative solutions into traditional manufacturing processes. As the industry evolves, leveraging cold heading dies may not only safeguard competitiveness but also contribute to a more sustainable and resilient food supply chain.

In modern manufacturing processes, the durability of cold heading dies plays a pivotal role in driving sustainable production practices. As industries increasingly prioritize energy efficiency and environmental impact, the adoption of advanced cold heading dies can significantly enhance manufacturing outcomes. According to recent market studies, the aerospace cold forging market is projected to reach USD 7.49 billion by 2032, culminating in a compound annual growth rate (CAGR) of 3.20% from 2025 to 2034. This growth is largely attributed to the rising demand for lightweight materials that improve fuel efficiency and reduce emissions.

Technological advancements, such as the implementation of a smart cold forging die life cycle management system, are unlocking new efficiencies by enabling real-time monitoring of forging loads. This innovative approach not only extends the life of the dies but also minimizes energy consumption during the forging processes. A notable study highlighted the positive influence of water mist cooling on the durability of punches, showcasing how additional cooling systems can enhance performance and sustainability in metal forming. As the industry continues to evolve, these developments in durability and efficiency are essential for meeting the growing global emphasis on sustainable manufacturing practices.

| Feature | Description | Benefits | Durability Rating |

|---|---|---|---|

| Material Composition | High-grade tool steel | Increases die lifespan and performance | A+ |

| Machining Precision | Tight tolerances up to 0.001 mm | Reduces material waste and increases product quality | A+ |

| Heat Treatment | Induction hardened | Enhances wear resistance under high stress | B+ |

| Cost-Effectiveness | Long-term investment | Lower replacement frequency reduces costs | A |

| Eco-Friendly Practices | Recyclable materials | Supports sustainable manufacturing processes | A+ |

In the realm of modern manufacturing, the versatility of cold heading dies has become a game changer for various industries. With customizability at the forefront, manufacturers can create unique designs tailored to specific applications, enhancing both efficiency and production rates. Recent studies reveal that the global cold heading market is projected to grow at a CAGR of 6.5% from 2023 to 2030, driven by the increasing demand for precision-engineered components across sectors like automotive, aerospace, and electronics.

Furthermore, technological advancements in cold heading die manufacturing—such as improved materials and innovative design techniques—have significantly boosted operational efficiency. This evolution not only maximizes output but also aligns with the demand for sustainable practices within the industry. As companies increasingly shift toward green manufacturing processes, the integration of energy-efficient technologies and reduced waste production in forging will become paramount. The combination of customization capabilities and sustainable practices positions cold heading dies at the forefront of the metal forging industry's dynamic landscape, ultimately contributing to market growth and resilience in a competitive environment.