Leave Your Message

-

Phone

-

E-mail

When selecting the right Cold Forging Die, it is crucial to consider multiple factors. According to John Smith, a leading expert in the cold forging industry, “Choosing the right die can make or break your production quality.” A well-designed Cold Forging Die not only influences the final product's precision but also impacts production efficiency.

Understanding your specific needs is essential. This may include the material type, desired tolerances, and part geometries. Each aspect plays a vital role in determining which die is suitable. For instance, a complex shape requires a more intricate die design. It's essential to reflect on your production capabilities and the potential limitations of available dies.

Additionally, it’s important to engage with suppliers. Ask questions about their experience and technology. Some manufacturers may not provide adequate support or customization options. The wrong choice can lead to costly errors in production. In this industry, perseverance and research can significantly enhance the outcome. Finding the ideal Cold Forging Die requires careful consideration and sometimes trial and error.

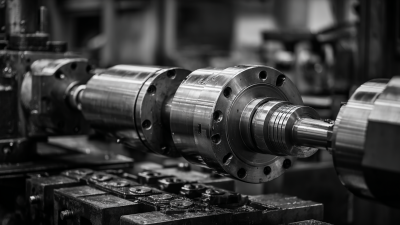

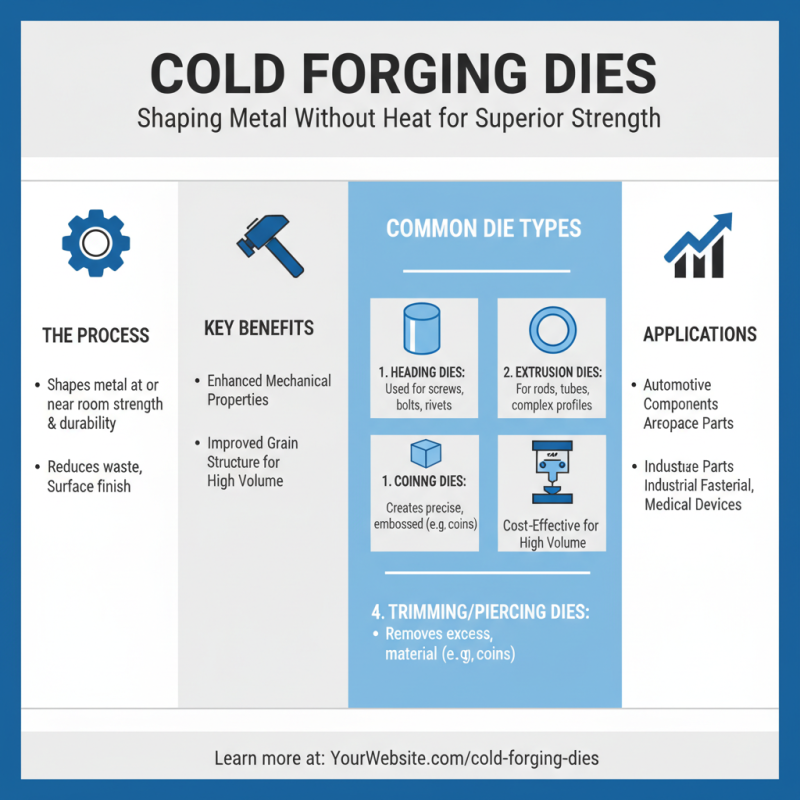

Cold forging dies play a crucial role in the manufacturing process. They shape metal without excessive heat. This method preserves the metal's strength. Different types of dies are available, each suited for specific applications. Next, we explore several die types.

Compression dies create solid parts. They are ideal for items needing tight tolerances. These dies can produce intricate shapes. Open dies, on the other hand, are simpler. They allow for more flexibility but aren't as precise. When choosing a die, consider the complexity of the part. Think about the desired material properties as well.

Some industries use cold forging extensively. Automotive manufacturing relies on these processes. Aerospace components also benefit from cold forging's strength. However, choosing the right die can be challenging. One must reflect on the specific requirements and limitations. Balancing cost and quality is often difficult. Proper research is essential before making a decision.

Choosing the right cold forging die can significantly impact production quality and efficiency. Several factors must be considered during this selection process. One critical aspect is the material compatibility. Different materials require specific die features. For instance, steel and aluminum behave uniquely under pressure, influencing die design.

The die's geometry plays a vital role too. Complex shapes may require advanced tooling. However, intricate designs can lead to higher costs and longer lead times. Balancing precision and cost is essential. According to industry reports, around 70% of manufacturing inefficiencies stem from improper die selection.

Tip: Collaborate with design engineers early in the process. Their insights can help streamline production.

Another factor is the anticipated production volume. Higher volumes often justify the investment in more durable dies. However, for small batches, simpler designs may suffice. It's crucial to reflect on your long-term needs versus immediate project demands. Many companies I’ve observed overlook this aspect and face increased expenses later.

Tip: Always conduct a cost-benefit analysis before making decisions. This approach could save resources and time in the long run. Consider gathering feedback from other teams to minimize risks related to die selection.

Selecting the right material for cold forging dies is critical for ensuring durability and performance. The die material affects the lifespan and efficiency of the forging process. For instance, tool steels like D2 and H13 are popular choices due to their high wear resistance. Research shows that dies made from high-carbon steel have a lifespan of up to 30% longer. This significantly reduces the need for frequent replacements.

However, material choice is not just about hardness. Thermal stability also plays a vital role. Reports indicate that inadequate thermal properties can lead to die failure during operations. Many professionals overlook this aspect. This can result in unexpected downtime and additional costs.

Moreover, the manufacturing process itself impacts the final die’s performance. Poorly processed steel can develop micro-cracks. These imperfections might not be visible initially. They can compromise the die's integrity over time. Investing in high-quality materials and reliable processing methods is essential. It ensures that the die can withstand repeated stresses in cold forging operations.

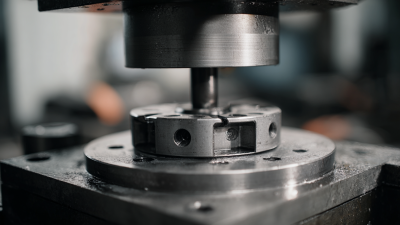

Choosing the right cold forging die requires attention to design features and specifications. The die must accommodate the specific material you intend to forge. Common materials include steel, aluminum, and brass, each with unique requirements. The tensile strength and ductility of the material play crucial roles in die selection.

Die geometry is equally important. A well-designed die must have precise dimensions. Uneven surfaces can lead to defects in the final product. Additionally, consider the die's cooling channels. These features help maintain the correct temperature during forging, ensuring consistent results. If a die overheats, it may warp or fail, leading to costly downtime.

Pay attention to the die's weight and balance. A heavy die can affect the forging machinery's performance. Light dies may not withstand high pressure effectively. Inspecting the quality of the die materials is essential. Inferior materials might result in cracks and shorten the die’s lifespan. Each detail counts when choosing the right cold forging die for your needs.

Choosing the right cold forging die is crucial. It heavily impacts the quality of your components. Evaluate the expertise of manufacturers carefully. Their knowledge can guide you in selecting the right die for your specific needs.

Look for manufacturers with a solid track record. Experience counts when it comes to die selection. A knowledgeable partner can provide insights into material selection and design. However, don’t hesitate to ask questions. Clarifying your doubts fosters a better understanding of the process.

Consider the support offered by the manufacturer post-purchase. Will they assist with maintenance? Are they available for troubleshooting? These factors play a vital role in your long-term satisfaction. Sometimes, manufacturers may not be as responsive as expected. This gap in support could lead to delays and frustrations. Aim for a supportive relationship that can evolve over time.