Leave Your Message

-

Phone

-

E-mail

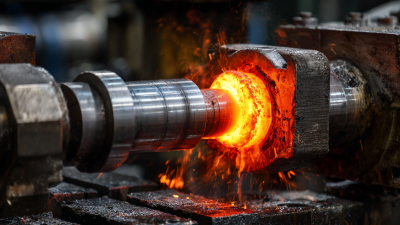

As industries continue to evolve and demand for advanced materials and techniques increases, the "Hot Forging Part" sector stands out as a beacon of innovation. In the words of Dr. Emily Chen, a leading expert in forging technology, "The future of Hot Forging Part innovations lies in our ability to integrate cutting-edge materials science with traditional manufacturing processes." This sentiment encapsulates the shift towards more efficient, resilient, and lighter components that can meet the rigorous demands of modern applications.

In 2025, we anticipate groundbreaking developments that will reshape the landscape of hot forging. From enhanced material compositions to revolutionary process adaptations, the top five innovations to watch will not only redefine the capabilities of Hot Forging Parts but also set new industry standards. These advancements promise to optimize production processes, reduce energy consumption, and ultimately lead to more sustainable manufacturing practices.

As we delve into these exciting innovations, it becomes crucial to recognize the role of collaboration between engineers, material scientists, and manufacturers. Together, they will harness the potential of Hot Forging Parts to push the boundaries of what is possible, paving the way for a new era of industrial excellence.

As we look forward to 2025, the field of hot forging technology continues to evolve with significant innovations that promise to enhance efficiency and product quality. One of the most pressing trends is the integration of advanced automation and robotics within the hot forging process. This shift not only increases production rates but also minimizes human error, leading to more consistent and high-quality forged parts.

Tip: Investing in automation can dramatically streamline your production without sacrificing flexibility. Consider starting with smaller, modular robotic units that can adapt to various tasks in the forging line.

Another emerging trend is the use of advanced materials designed specifically for hot forging. These materials, including high-strength alloys and composites, allow for greater durability while reducing weight in the final products. Such innovations are particularly beneficial in industries like automotive and aerospace, where performance and efficiency are critical.

Tip: Stay informed about new material developments and consider testing them in small batch productions. This can help you assess their compatibility with your existing processes and potential advantages for your products.

The integration of AI and machine learning into hot forging processes marks a significant leap forward in manufacturing technology.

By analyzing vast amounts of historical forging data, these advanced systems can identify patterns and optimize parameters in real-time, leading to improved product quality and reduced waste. For instance, predictive analytics can foresee potential defects before they occur, allowing manufacturers to adjust processes proactively and enhance overall efficiency.

Additionally, AI-driven simulations enable engineers to model and refine forging techniques without the need for extensive physical trials. This not only speeds up the development cycle but also empowers companies to explore innovative designs that were previously deemed too complex or costly.

As machine learning algorithms continue to evolve, their ability to learn from new data ensures that forging practices will become more adaptive, paving the way for bespoke solutions tailored to specific industry needs.

The future of hot forging is, thus, poised to become substantially smarter and more agile.

The hot forging industry is undergoing a transformative phase as manufacturers increasingly prioritize sustainable practices to reduce their carbon footprint. According to a report by the International Energy Agency (IEA), industrial processes, including forging, contribute to nearly 25% of global CO2 emissions. This alarming statistic has prompted many companies to adopt energy-efficient technologies and renewable energy sources. Notably, the implementation of electric heating methods in hot forging can potentially reduce energy consumption by up to 40%, translating into significant emissions reductions.

Moreover, advancements in material science are enabling the development of lower-carbon alternatives to traditional metals. A study published by the World Steel Association highlights that using high-strength steels can reduce the amount of material needed, thereby cutting down on the energy required for production and processing. Companies are increasingly integrating circular economy principles, where scrap metals from production are recycled and reused, further minimizing waste and environmental impact. As these innovations take hold, the hot forging industry is not only optimizing its operational efficiency but also taking a crucial step toward a more sustainable future.

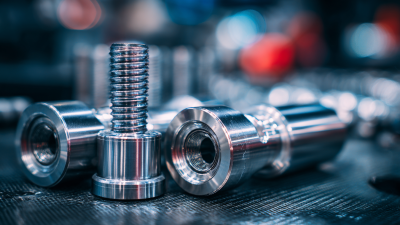

In the dynamic world of hot forging, advanced materials are playing a crucial role in enhancing performance and durability. The integration of high-strength alloys and composite materials is revolutionizing traditional forging processes, allowing manufacturers to create components that not only withstand extreme conditions but also reduce weight. Innovations such as titanium-based alloys and advanced steel grades are becoming increasingly popular, providing a blend of toughness and resilience that is essential for industries like aerospace and automotive.

Moreover, the application of materials like carbon fiber reinforced polymers is pushing the limits of what's possible in forging. These materials offer remarkable impact resistance and fatigue strength, making them ideal for critical components that require longevity and reliability. As manufacturers continue to explore these advanced materials, the potential for reduced manufacturing costs and improved product performance becomes increasingly apparent, setting the stage for groundbreaking innovations in the forging sector by 2025.

The hot forging industry is experiencing significant advancements driven by automation, which promises to enhance both efficiency and precision. As automotive sales continue to rise, the demand for high-quality forged components is surging. To meet this growing need, companies are increasingly turning to automated processes that streamline production lines and reduce human error. This integration of cutting-edge robotics not only improves the speed of manufacturing but also ensures consistent quality in the finished products, crucial for critical automotive applications like engine parts.

Innovations in precision manufacturing are transforming the landscape of hot forging, spearheaded by advancements in technology. The adoption of AI-powered optimization allows manufacturers to fine-tune processes in real-time, leading to better material utilization and reduced waste. Furthermore, the development of ultra-hard coatings enhances tool longevity and performance, ensuring that forging tools can withstand the rigors of industrial production. By embracing these innovative practices, the hot forging sector is not just keeping pace with market demands, but is also setting new standards for quality and sustainability in manufacturing.